Casting burning-on device and method

A casting and melting pool technology, applied in the field of casting repairing equipment, can solve the problems of inclusions, large size, scrapping of castings, etc., and achieve the effect of avoiding overall scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

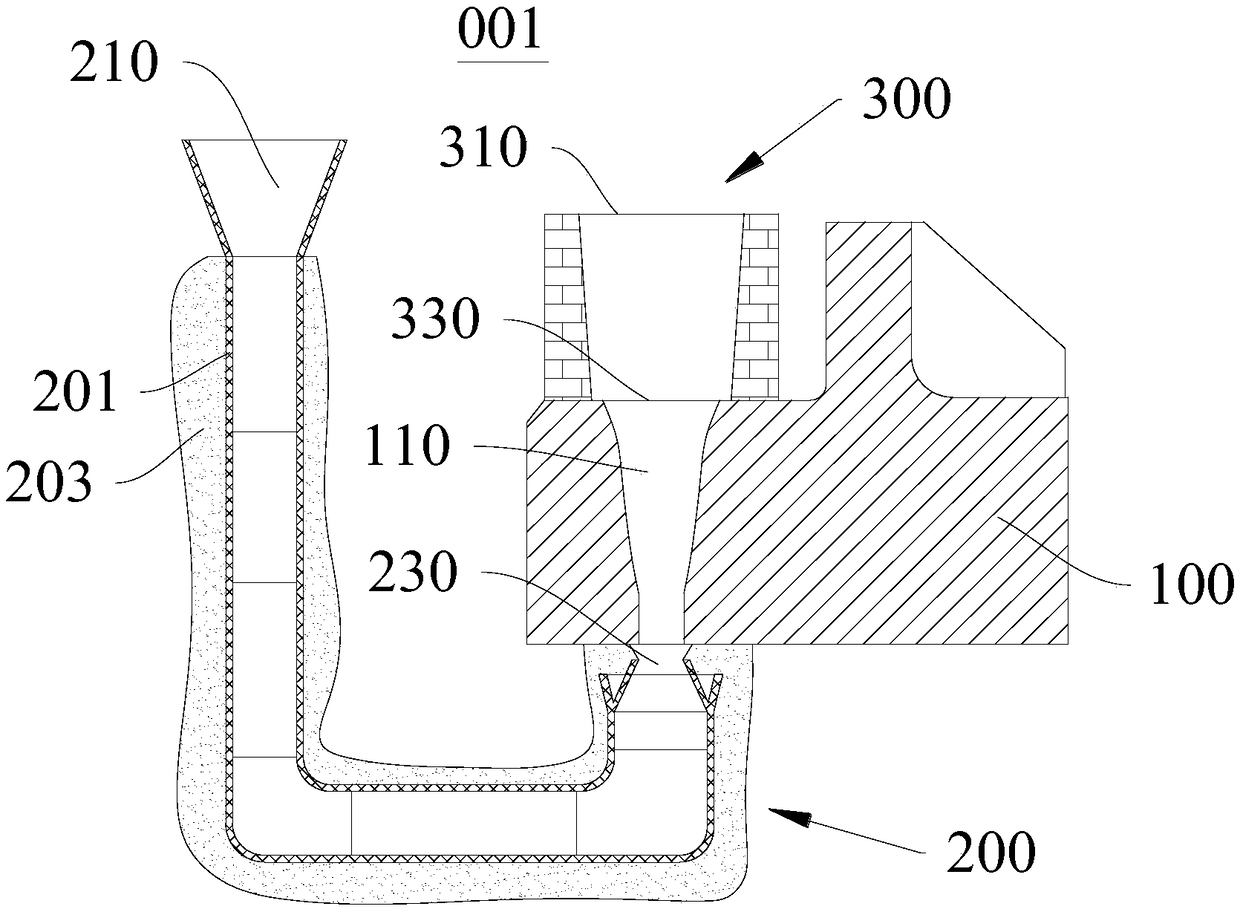

[0036] This embodiment provides a casting 100 welding device 001, please refer to figure 1 , this casting 100 welding repair device 001 is used for welding and repairing the defective part 110 of the casting 100. The defective part 110 here should penetrate the opposite sides of the casting 100. If it does not penetrate, it needs to be artificially penetrated by grinding to facilitate the subsequent metal fluid filling.

[0037] Casting 100 welding device 001 includes overflow channel 200 and flushing molten pool 300; overflow channel 200 includes gate end 210 and is used to align the water outlet end 230 of the lower end opening of defective part 110, and water outlet end 230 is provided with for sealing The first sealing member of the connecting part of the water outlet 230 and the casting 100 .

[0038] In this embodiment, the first seal is formed by filling the gap between the water outlet 230 and the casting 100 with resin sand, and the setting of the first seal ensures ...

Embodiment 2

[0046] This embodiment provides a casting 100 weld repair method, please refer to figure 1 In this casting 100 repairing method, the casting 100 repairing device 001 described in the first embodiment is used to repair the defective part 110 of the casting 100 .

[0047] Its specific implementation steps include:

[0048] The morphology of the defect 110 is analyzed, including that the defect 110 is mainly in the casting 100 , the size of the defect 110 , and the composition analysis of the defect 110 . According to the above analysis, the way of repairing the defect, the way of placing the casting 100 and the composition of the poured molten metal are determined.

[0049] The interior of the defective part 110 is polished and smoothed to eliminate sharp corners. If the defective part 110 is a perforation defect, the edges and corners on both sides of the perforation are blunted directly; two sides.

[0050] After the castings 100 are placed, they are spliced with refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com