Stone reversing-laying technology capable of reducing cracks

A technology of stone and craftsmanship, which is applied in the field of stone anti-beating technology, can solve the problems of different expansion coefficients, uneven concrete density, affecting the beauty of stone and wall stability, and achieve the effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

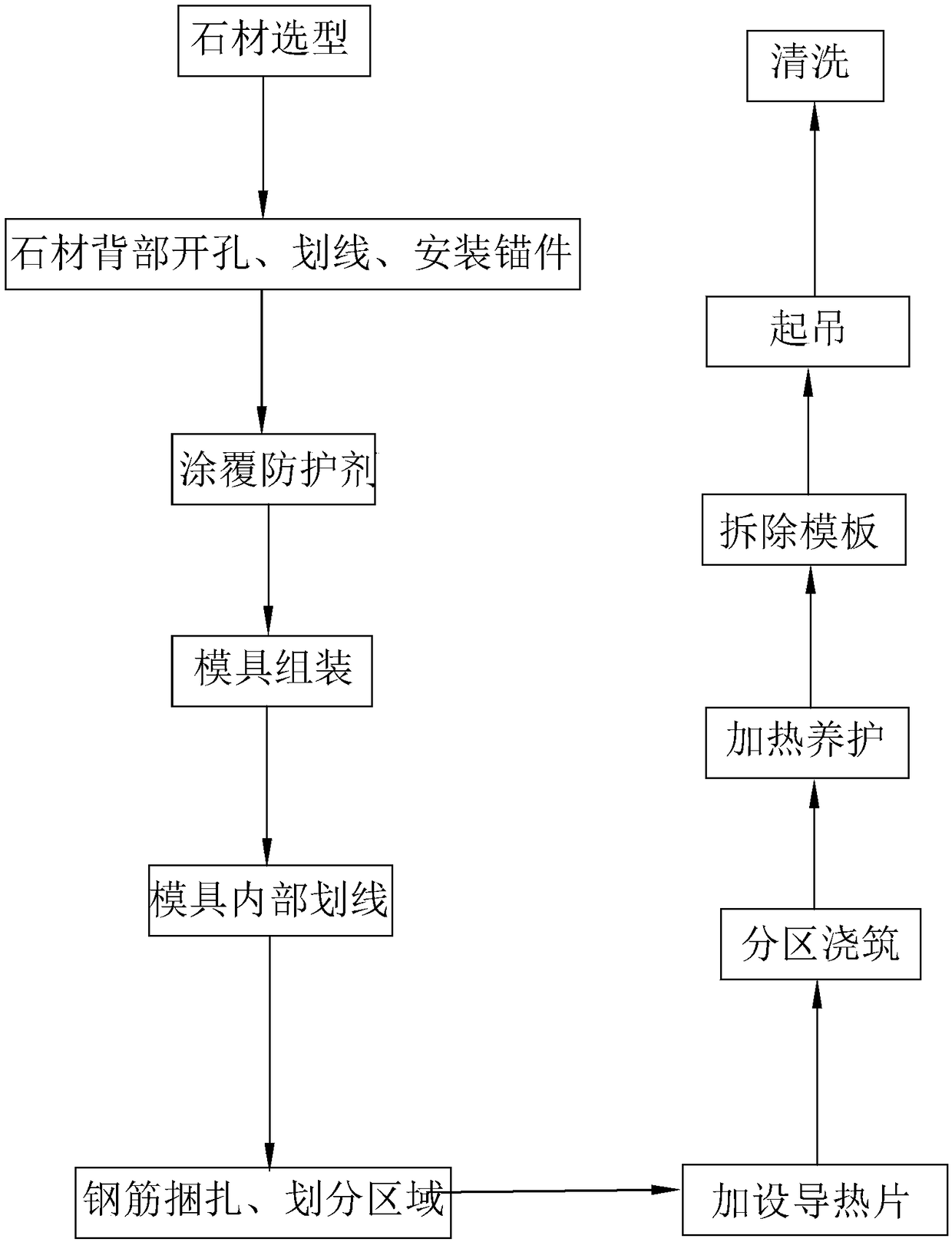

[0028] Embodiment 1: A kind of stone anti-beating process that reduces cracks, including:

[0029]Step 1, stone selection, choose arc stone, the arc of the stone is the same as the arc of the column to be formed, choose the size and specification of the stone according to the column to be made, and use granite and marble as the best types, and can Choose some other stones with better color, check the stones when purchasing, remove some stones with cracks, weathering and impurities, and reduce the collision of stones in the process of transportation and handling of the selected stones.

[0030] Step 2, draw a line on the back of the stone, measure and mark the hole position, the drilling machine drills the inner surface of the stone according to the marked hole position, and each stone is at the four corners or the center of the stone Open 4-5 pairs of holes, the depth of the drill bit should be 15-25mm, then inject the glue-planting bars into each hole, and then directly inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com