Light transmitting concrete light guide module and application method thereof

A technology of light-transmitting concrete and light-guiding columns, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult to guarantee construction quality, easy damage to light-transmitting materials, damage to mold structure, etc. The effect of improving strength, quality, safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

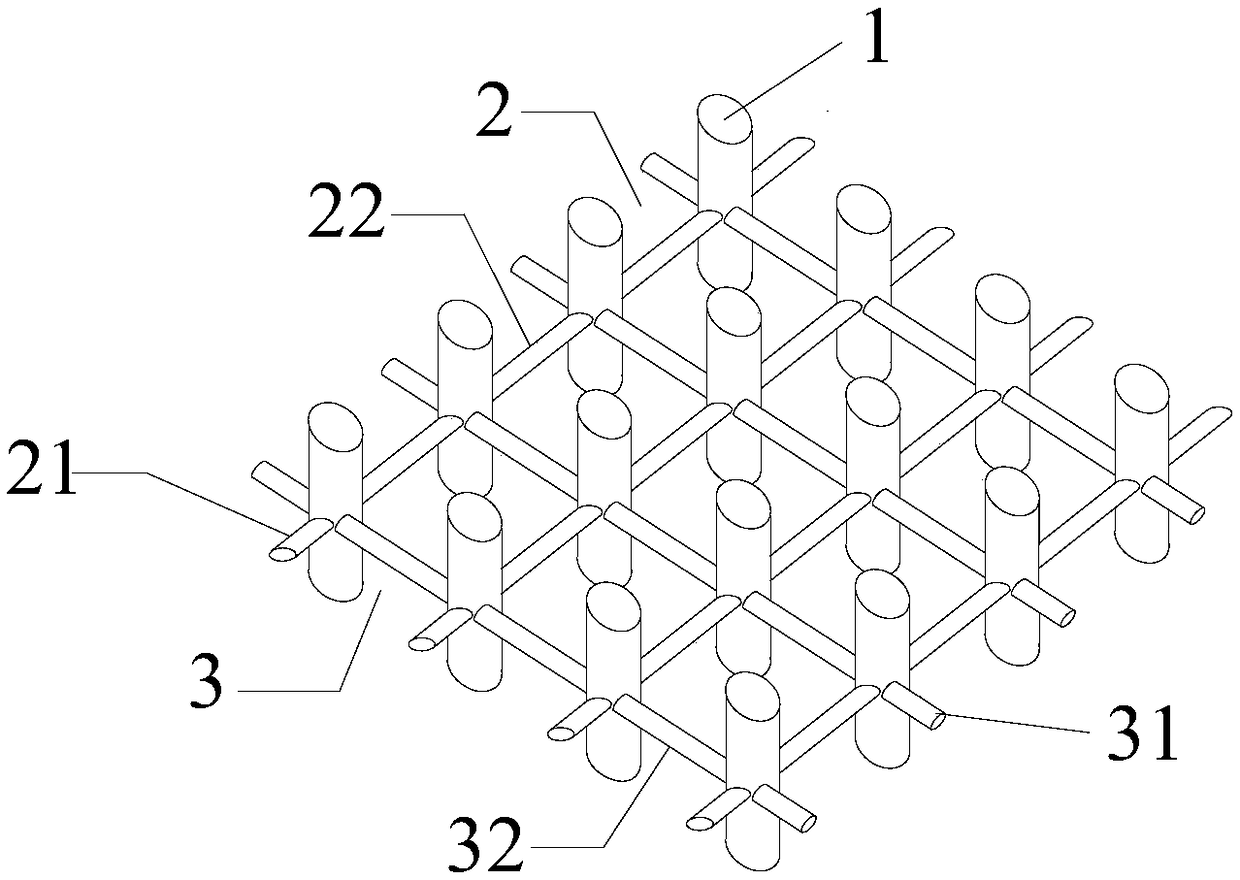

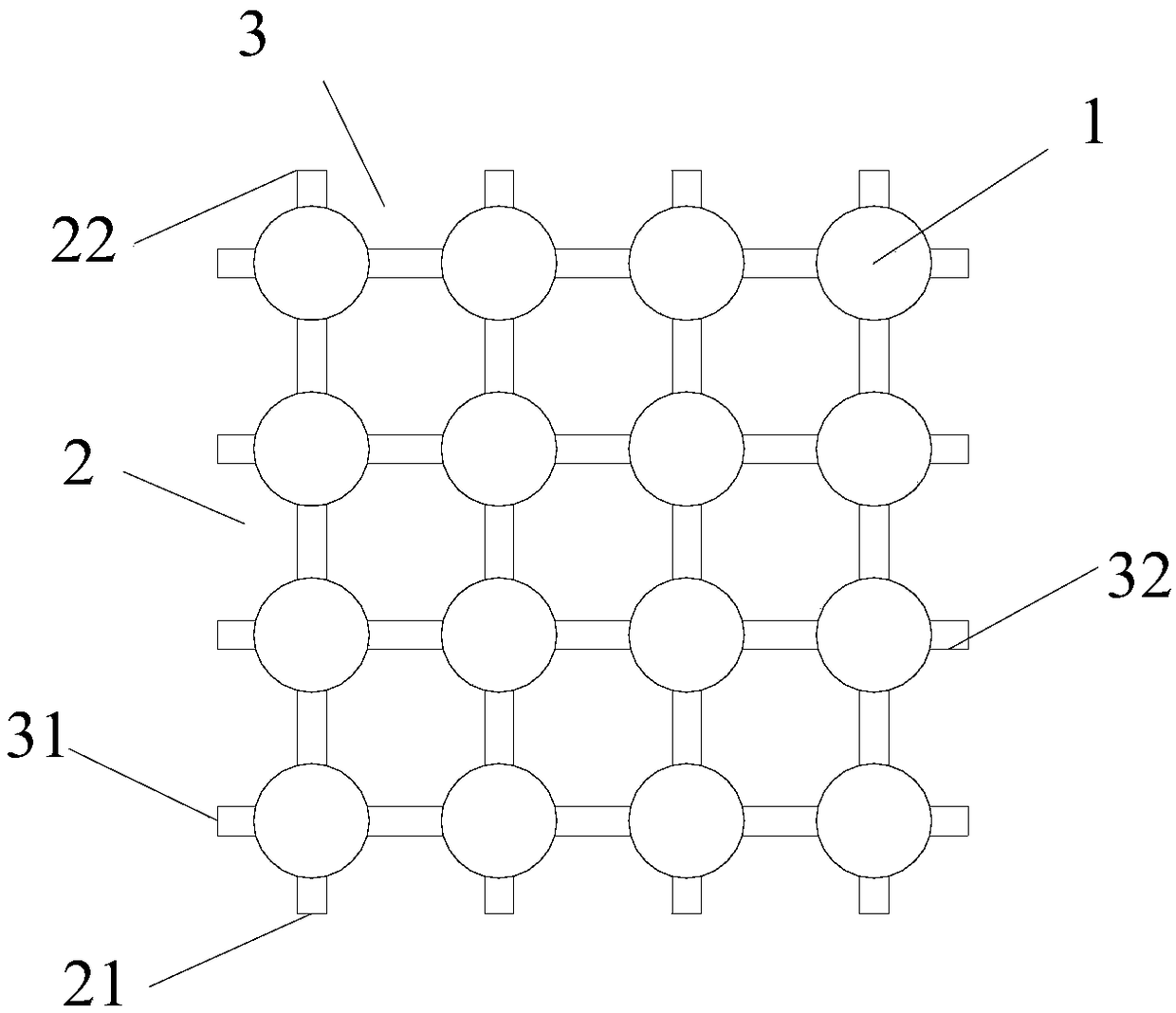

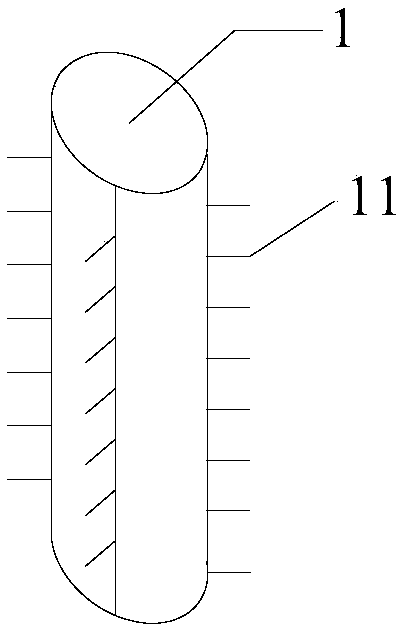

[0033] like figure 1 As shown in -2, a light-transmitting concrete light guide column module includes sixteen light guide columns 1, longitudinal connecting columns 2, and horizontal connecting columns 3. The sixteen light guiding columns 1 are arranged in a vertical and horizontal matrix, and each horizontal The middle parts of the light guide columns 1 of the rows are all connected by the horizontal connecting columns 3, and the middle parts of the light guiding columns 1 of each longitudinal row are connected by the longitudinal connecting columns 2; Any fixing measures can well fix its position, which greatly facilitates the arrangement of light-guiding materials in the light-transmitting concrete and ensures the construction quality; In order to play a role similar to the steel mesh, it improves the strength of the light-transmitting concrete.

[0034] The light guiding column 1 , the longitudinal connecting column 2 and the horizontal connecting column 3 are integrally ...

Embodiment 2

[0041] Embodiment 2 is the method of using the light-transmitting concrete light guide column module of Embodiment 1, comprising the following steps:

[0042] (1) According to the area of the light-transmitting concrete to be constructed, calculate the number of light-transmitting concrete light-guiding column modules required, and prepare a sufficient number of light-transmitting concrete light-guiding column modules;

[0043] (2) Lay the first light-transmitting concrete light guide column module close to the corner of the mold box;

[0044](3) Apply glass glue to each lateral end connection column 31 on one side of the second light-transmitting concrete light guide column module, and coat the horizontal end connection column 31 of the second light-transmitting concrete light guide column module with glass glue. The first piece of light-transmitting concrete light-guiding column module is closely bonded to the lateral end connecting columns 31 on the opposite side of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com