Designing method for realizing self-folding of high polymer by macroscale

A design method and polymer technology, applied in the field of polymer self-folding design, can solve problems such as difficult control of experimental conditions and complicated experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A design method for realizing polymer self-folding on a macro scale, the steps of the design method are as follows:

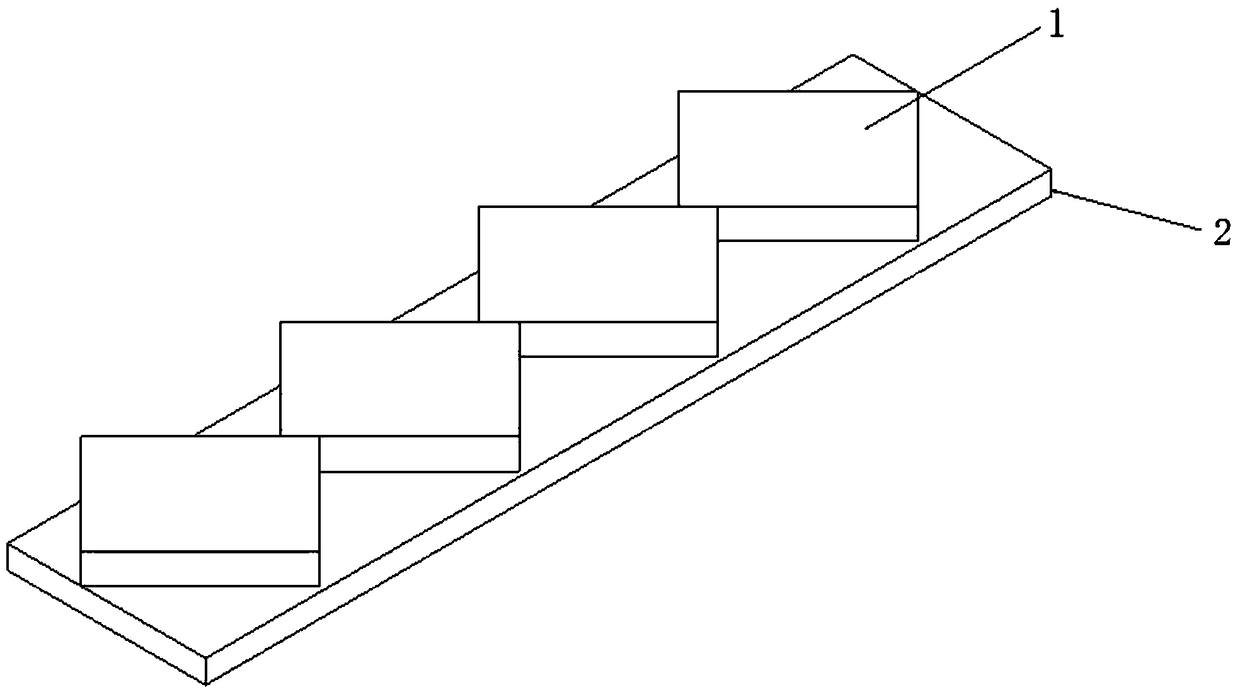

[0039] (1) be length 5cm, the high polymer (1) sheet material of glass state that width is 1cm carries out tensile deformation with stretching machine, and its final length uniform deformation is 180%, and length is 9cm, and width is 0.7cm , in this embodiment, the polymer (1) is polyethylene terephthalate-1,4-cyclohexanedimethanol;

[0040] (2) Cut the polymer (1) pre-deformed in step (1) into small sections with a length of 1 cm, and then cut the rubber (2) into strips with a length of 6 cm and a width of 1 cm. In this embodiment, Rubber (2) is silicone rubber;

[0041] (3) Use a rubber surface treatment agent to treat the strip-shaped rubber (2), the polymer (1) is superimposed on the surface of the rubber (2), and the angle between the two is 45°, and the polymer (1) is glued with instant adhesive (1) The surface in contact with the rubber (2) is p...

Embodiment 2

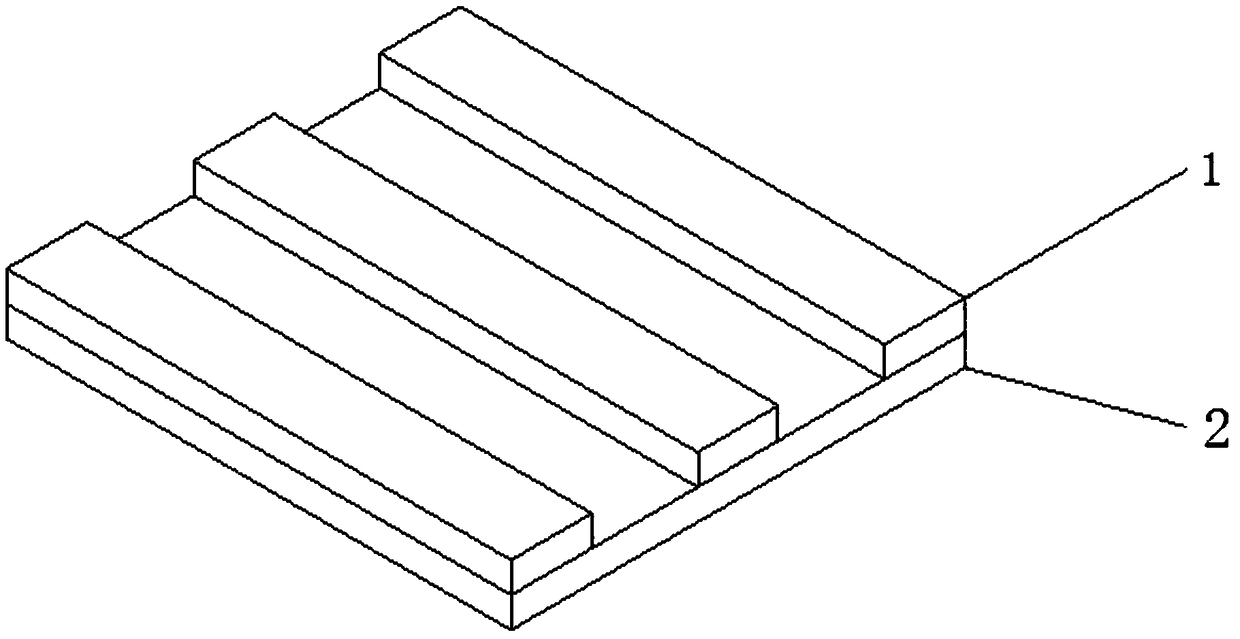

[0048] A design method for realizing polymer self-folding on a macro scale, the steps of the design method are as follows:

[0049] (1) be length 5cm, the high polymer (1) sheet material of glass state that width is 1cm carries out tensile deformation with stretching machine, and its final length uniform deformation is 180%, and length is 9cm, and width is 0.7cm , in this embodiment, the polymer (1) is polyethylene terephthalate-1,4-cyclohexanedimethanol;

[0050](2) Cut the polymer (1) pre-deformed in step (1) into a small section with a length of 3 cm, and then cut the rubber (2) into a sheet with a length of 5 cm and a width of 3 cm. In this embodiment, Rubber (2) is silicone rubber;

[0051] (3) Use a rubber surface treatment agent to treat the strip-shaped rubber (2), and evenly superimpose the small segment of the high polymer (1) on the surface of the rubber (2), and the length of the small segment of the high polymer (1) and the sheet rubber ( 2) are parallel to each...

Embodiment 3

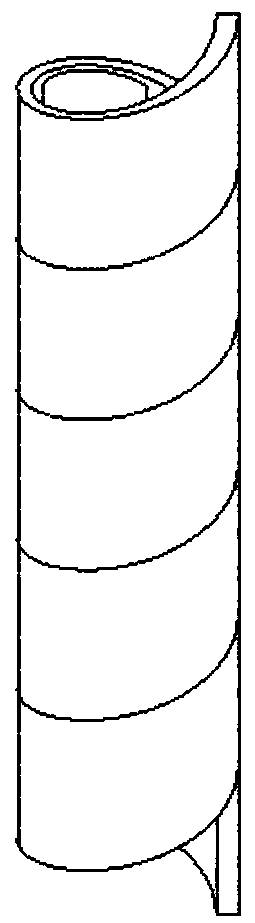

[0058] A design method for realizing polymer self-folding on a macro scale, the steps of the design method are as follows:

[0059] (1) be length 5cm, the high polymer (1) sheet material of glass state that width is 1cm carries out tensile deformation with stretching machine, and its final length uniform deformation is 180%, and length is 9cm, and width is 0.7cm , in this embodiment, the polymer (1) is polyethylene terephthalate-1,4-cyclohexanedimethanol;

[0060] (2) The polymer (1) after step (1) pre-deformation is not processed, and then the rubber (2) is cut into strips with a length of 9 cm and a width of 0.7 cm. In this embodiment, the rubber (2) is Silicone Rubber;

[0061] (3) Use a rubber surface treatment agent to treat the strip-shaped rubber (2), and evenly superimpose the high polymer (1) on the surface of the rubber (2), and the high polymer (1) and the strip-shaped rubber (2) Parallel to each other (there is an angle of 0° between the two), use instant adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com