A hybrid transmission system

A hybrid and hybrid drive technology, applied in the automotive field, can solve the problems of complex torque output structure control, and achieve the effects of facilitating space loading, reducing design complexity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

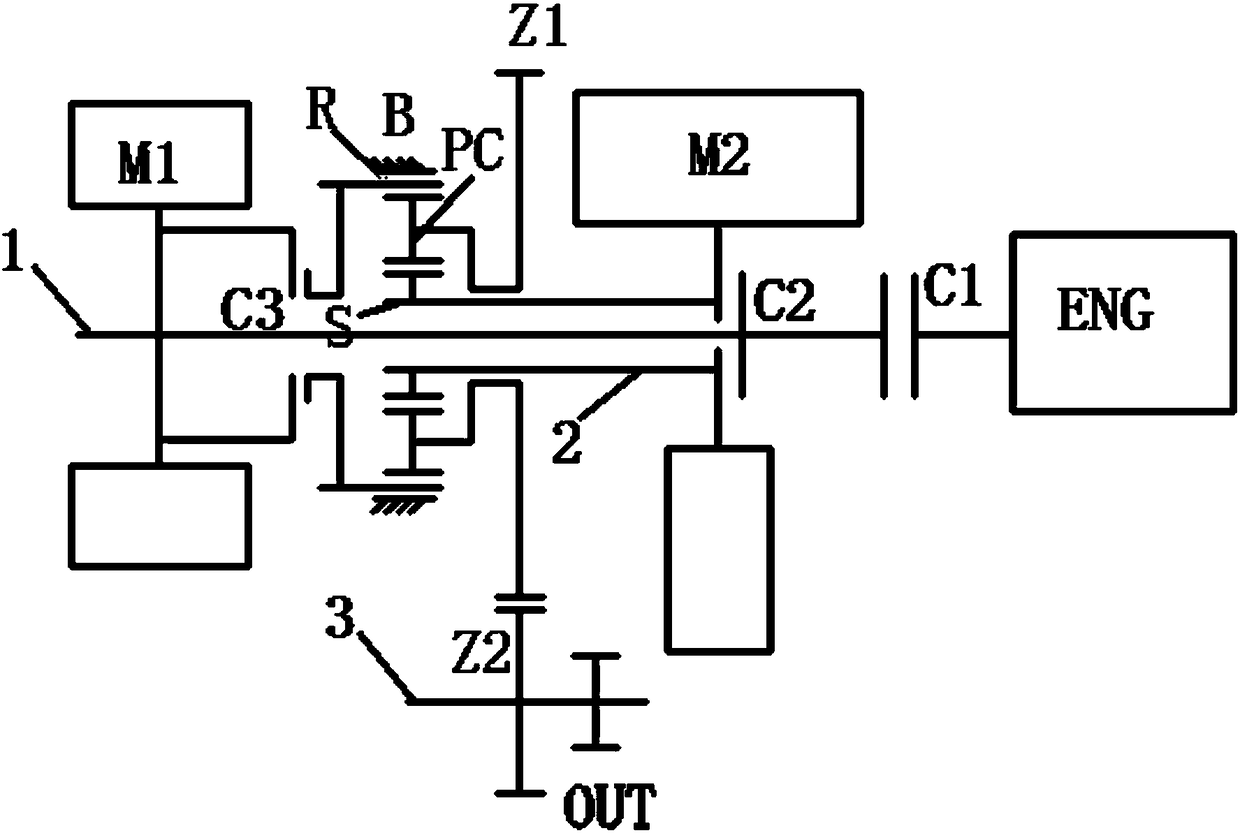

[0024] refer to figure 1 , is a schematic diagram of a hybrid transmission system described in an embodiment of the present invention, and may specifically include:

[0025] engine ENG, first motor M1 and second motor M2, first clutch C1, second clutch C2 and third clutch C3 and first transmission shaft 1, second transmission shaft 2 and third transmission shaft 3, planetary carrier PC, Brake B, first gear Z1 and second gear Z2, ring gear R, sun gear S, power output interface OUT, where:

[0026] The engine ENG is connected to the first clutch C1 through a crankshaft;

[0027] The planet carrier PC is engaged with the ring gear R and the sun gear S respectively to form a planetary row structure;

[0028] The planetary row structure is respectively directly connected with the first gear Z1 to output power;

[0029] The first motor M1 is selectively connected to the ring gear R through the third clutch C3, so as to output electric power to the planetary row structure;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com