A transport-erection integrated construction process for conveyors and large-tonnage bridge components

A technology of construction technology and transport vehicles, which is applied in the direction of transporting objects, goods transport vehicles, bridges, etc., and can solve problems such as long construction time of bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a transport vehicle.

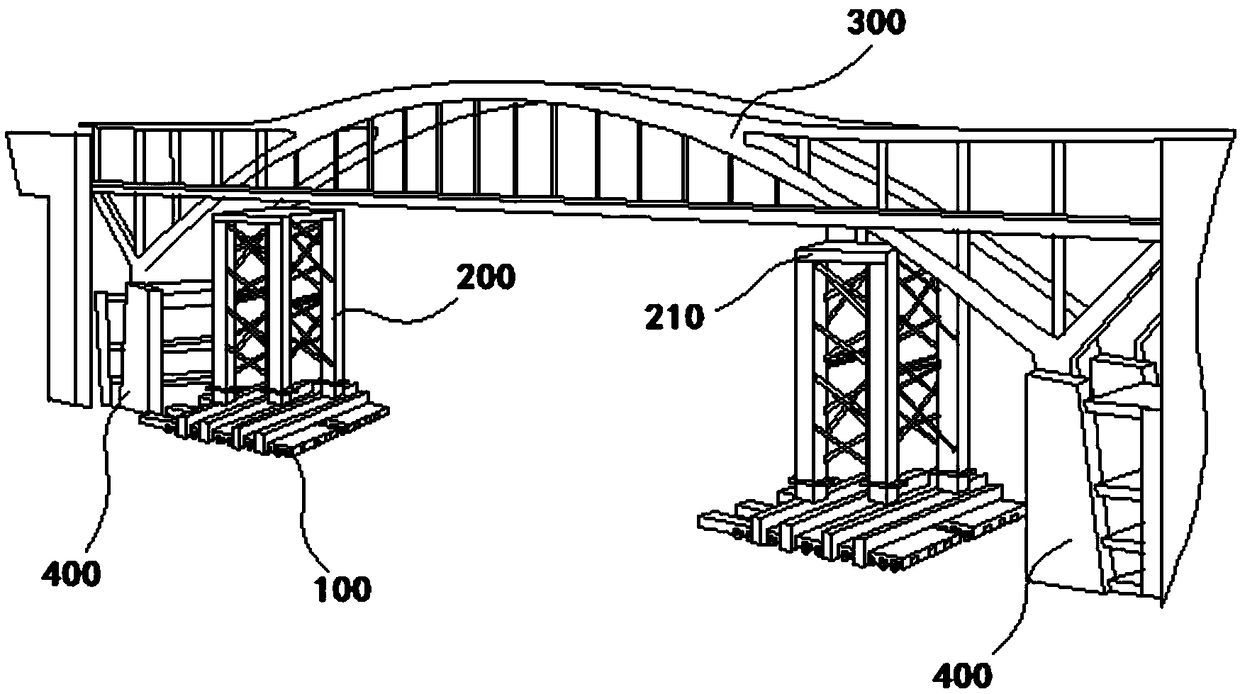

[0047] Please refer to figure 1 , the transport vehicle includes a self-propelled module transport vehicle 100 and a jacking device 200.

[0048] Wherein, the jacking device 200 is installed on the self-propelled module transport vehicle 100, and the jacking device 200 is used to output lifting motion.

[0049] The above self-propelled module transport vehicle 100 is the SPMT, which is mainly used for the transportation of heavy, large, high, and special-shaped structures. More than 50000 tons. It is widely used in engineering fields such as equipment manufacturing, petroleum, chemical, offshore oil, and bridge construction.

[0050] It should be noted that the self-propelled module transport vehicle 100 can use any of the existing technologies.

[0051] Likewise, the above-mentioned jacking device 200 can also adopt any one of the prior art.

[0052] In this embodiment, through the combined use of the self-propelled ...

Embodiment 2

[0061] This embodiment provides an integrated construction process for large-tonnage bridge components.

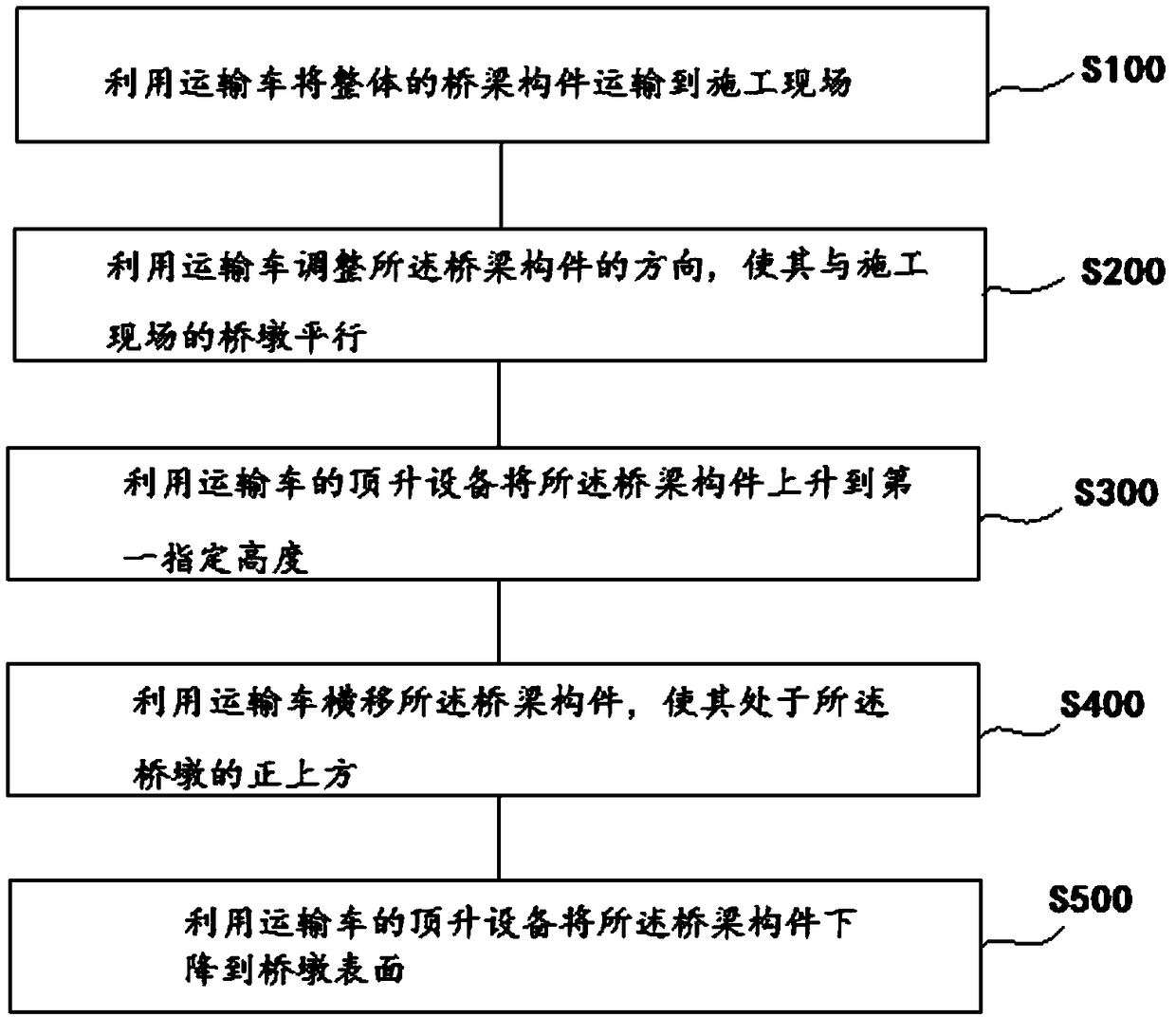

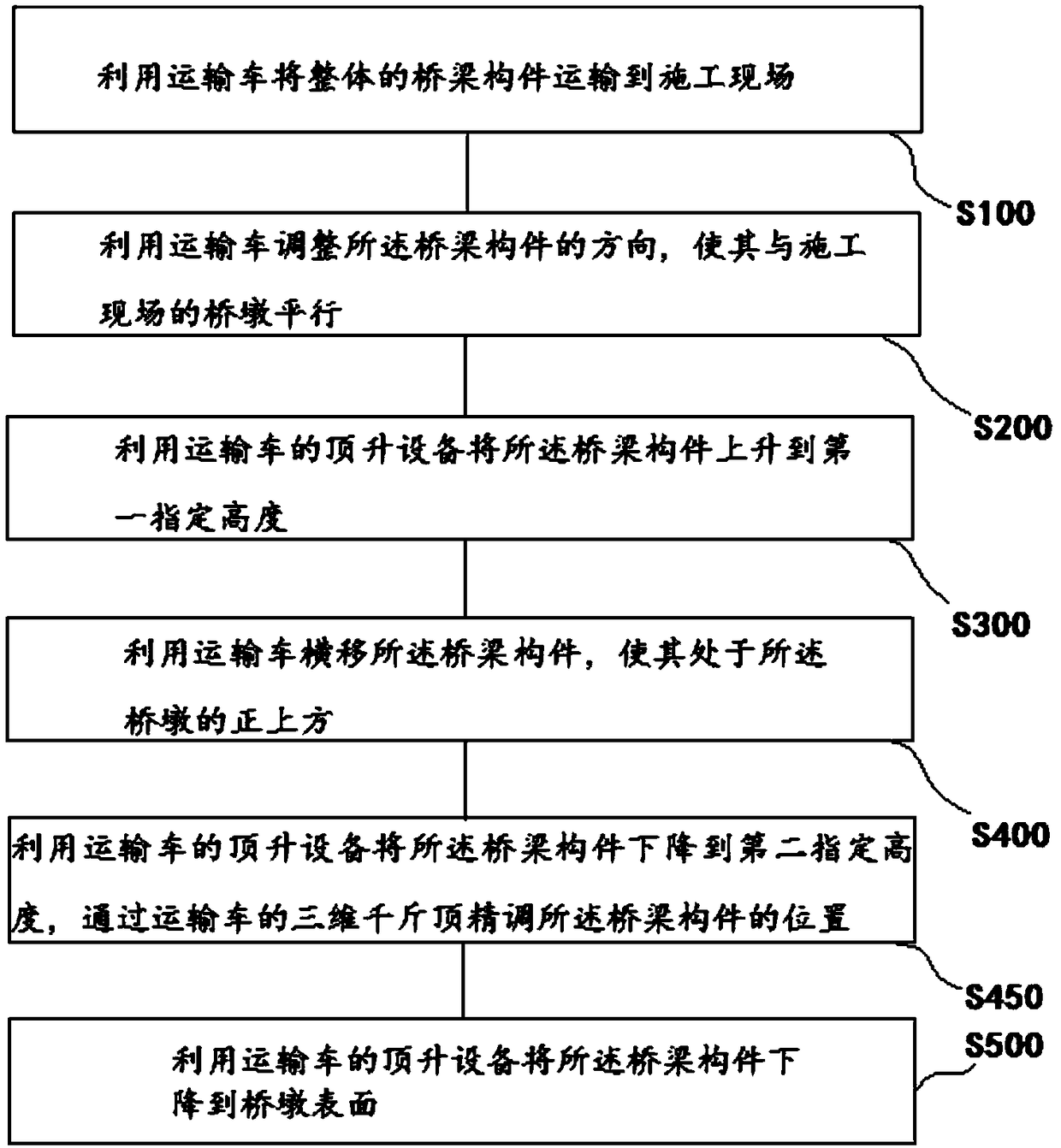

[0062] Please refer to figure 2 , in this embodiment, the integrated construction process of transporting frames includes the following steps:

[0063] S100, using a transport vehicle to transport the entire bridge component 300 to the construction site;

[0064] S200. Adjust the direction of the bridge component 300 with the transport vehicle so that it is parallel to the bridge pier 400 on the construction site;

[0065] S300, using the jacking device 200 of the transport vehicle to raise the bridge member 300 to a first specified height;

[0066] S400. Transversely move the bridge member 300 with a transport vehicle so that it is directly above the pier 400;

[0067] S500. Lower the bridge member 300 to the surface of the bridge pier 400 by using the jacking device 200 of the transport vehicle.

[0068] Wherein, the transport vehicle is introduced in detail in Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com