High-pressure jet grouting piling device and high-pressure jet grouting piling method with same

A technology of high-pressure rotary grouting pile machine and grouting port, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., which can solve the problems of uneven diffusion of grout, slow diffusion of grout, and inconsistent pile diameters, etc. Uniform diffusion speed, balanced and stable grouting pressure, uniform pile diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

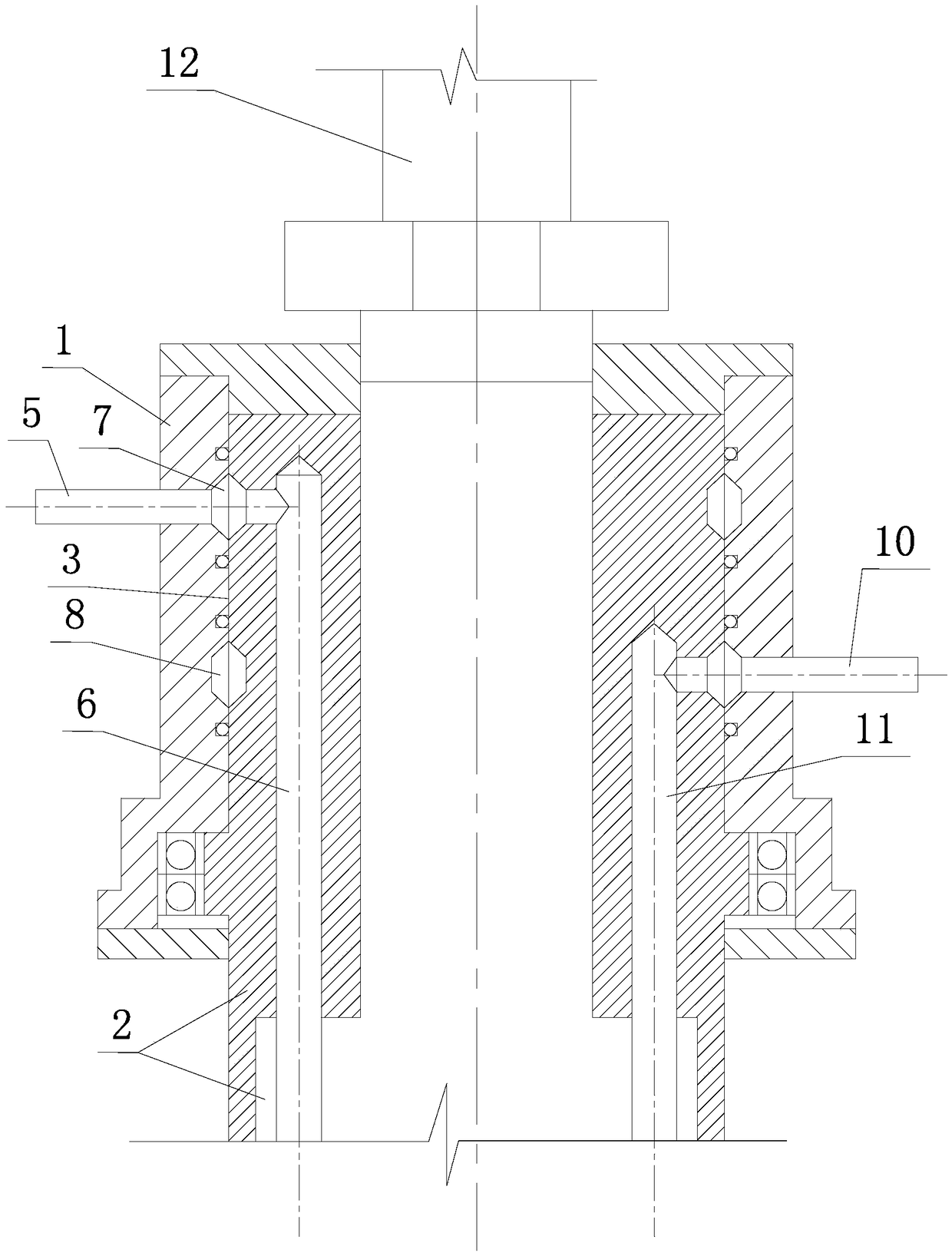

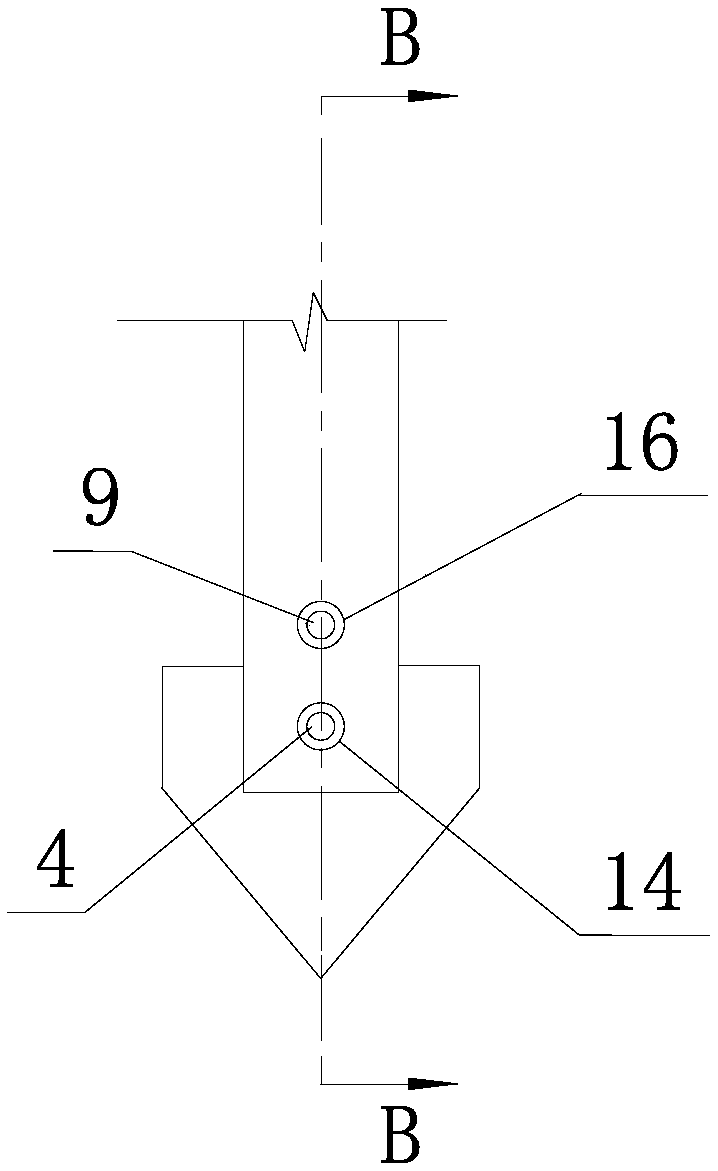

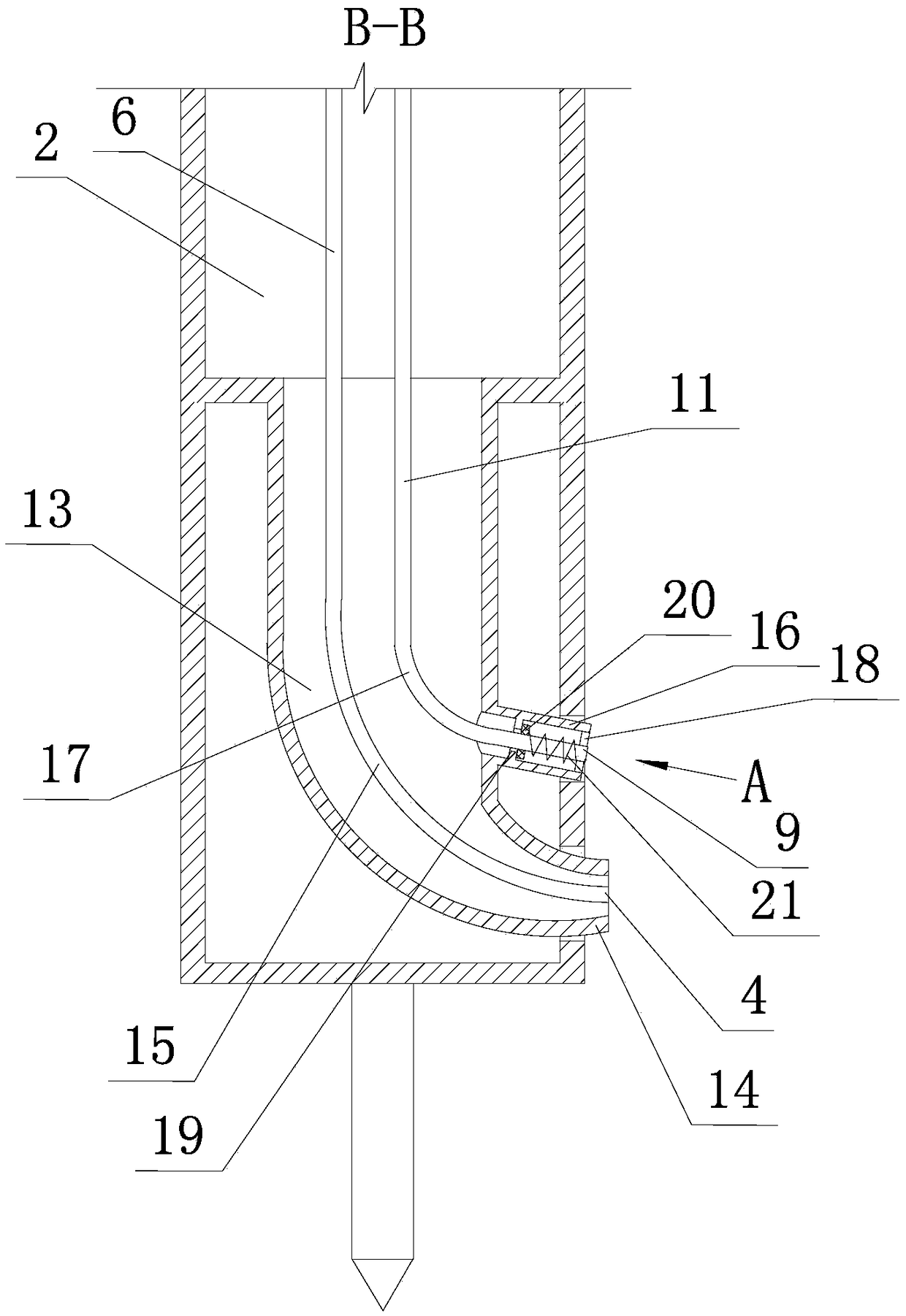

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the high-pressure rotary grouting pile machine of the present invention includes a power head 1, a drill pipe 2, a drill bit positioned at the lower end of the drill pipe 2, a first grouting pipe communicated with the first grouting pump, and a second grouting pump. The second grouting pipe

[0027] The power head 1 is provided with a cylindrical installation chamber 3. Since the power head 1 is a conventional prior art, only a part of the power head 1 is shown in the accompanying drawings of the application, that is, the installation chamber in the power head 1 3 side wall parts. The upper part of the drill rod 2 is rotatably installed in the installation chamber 3 of the power head 1 through bearings. An upper annular chamber 7 and a lower annular chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com