Manufacturing method of PN node of P-type pseudo-single crystal silicon solar cell

A manufacturing method and technology of quasi-single crystal silicon, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc. Performance and conversion efficiency and other issues, to achieve the effect of reducing the difference in battery square resistance and improving electrical performance and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

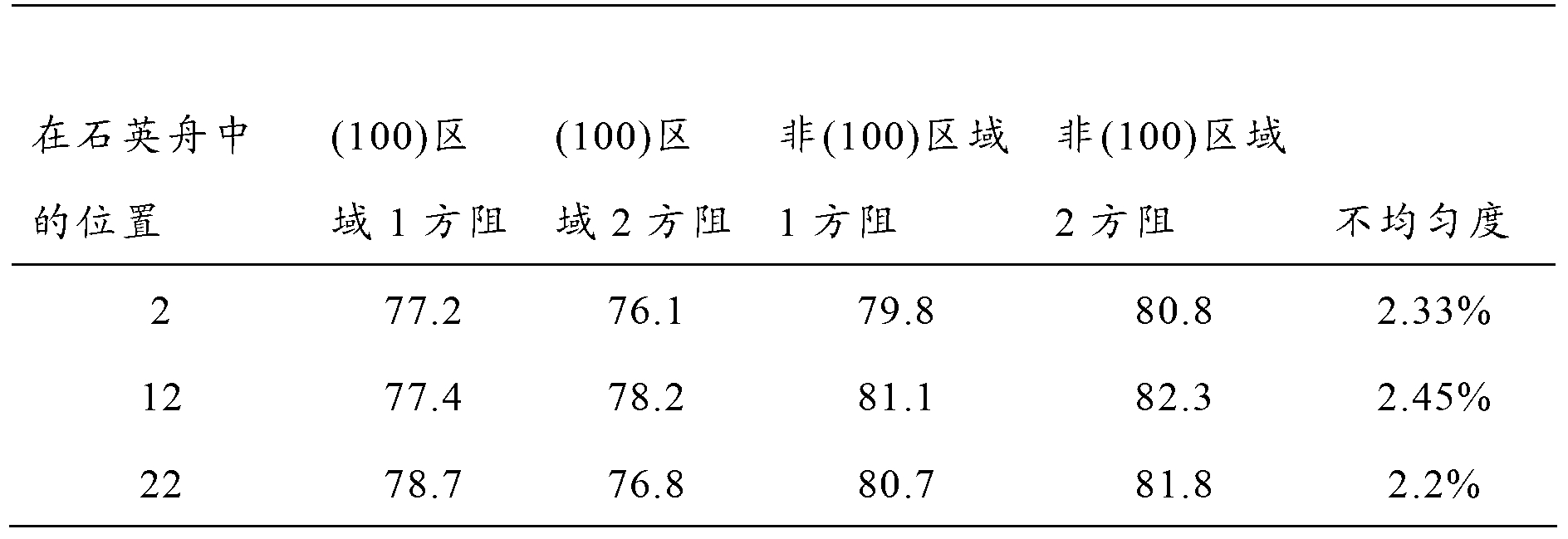

Embodiment 1

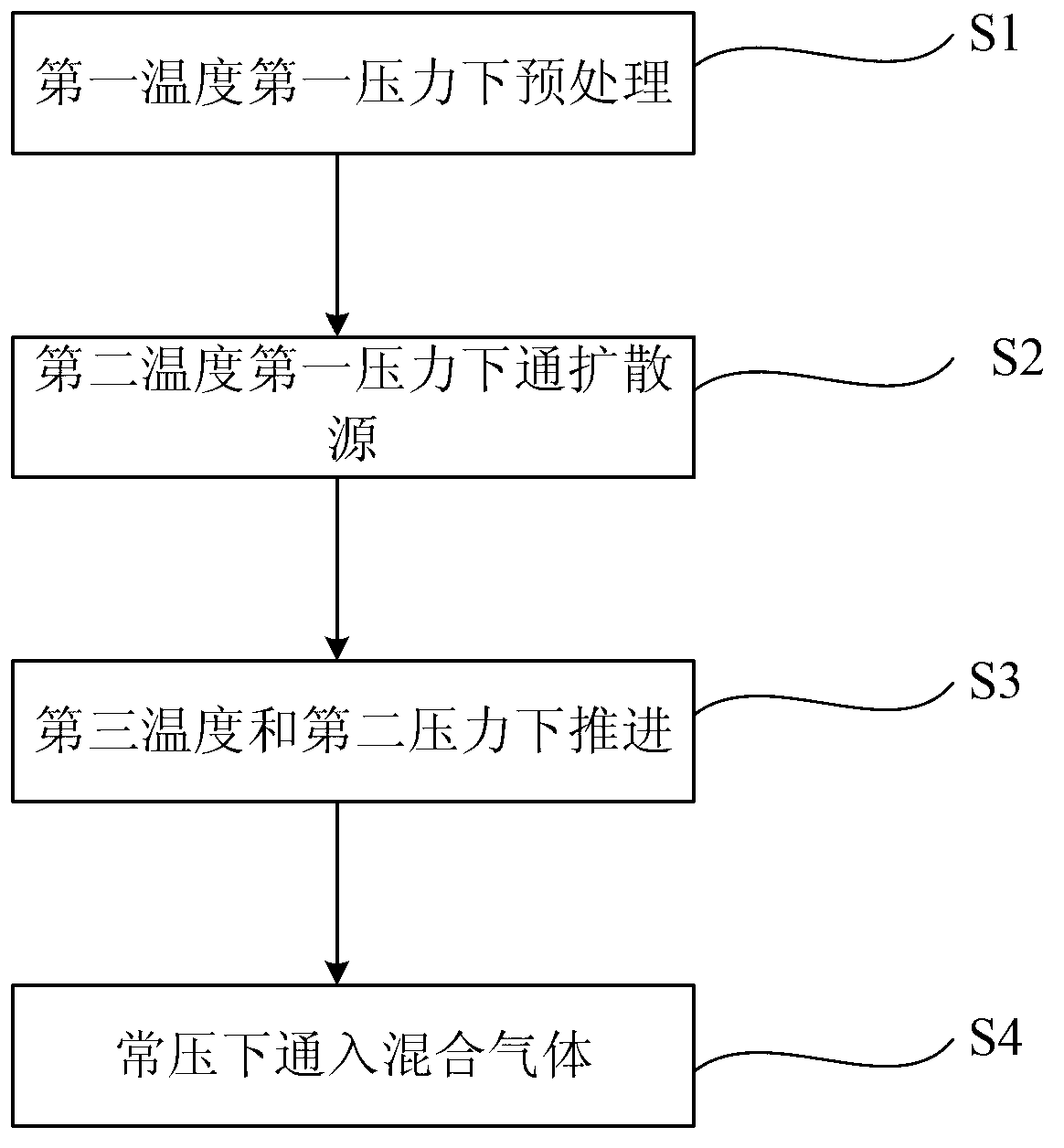

[0038] Put a set of P-type quasi-monocrystalline silicon wafers after texturing and cleaning into the diffusion furnace. In this embodiment, a set of P-type quasi-monocrystalline silicon wafers is specifically 25 pieces, which are carried by a quartz boat. Quasi-monocrystalline silicon wafers are processed as follows:

[0039] Adjust the temperature in the diffusion furnace to 750°C (that is, the first temperature), and pretreat the P-type quasi-monocrystalline silicon wafers at a pressure of -50pa (first pressure). The processing time is preferably 5-10 minutes ;

[0040] Then increase the temperature to increase the temperature in the diffusion furnace to 800°C (the second temperature), and carry phosphorus oxychloride into the diffusion furnace by nitrogen at a pressure of -50pa, maintaining the flow rate of phosphorus oxychloride at 1L / min, the duration is 10 minutes;

[0041] Then lower the temperature, stop the introduction of phosphorus oxychloride, keep the temperature in ...

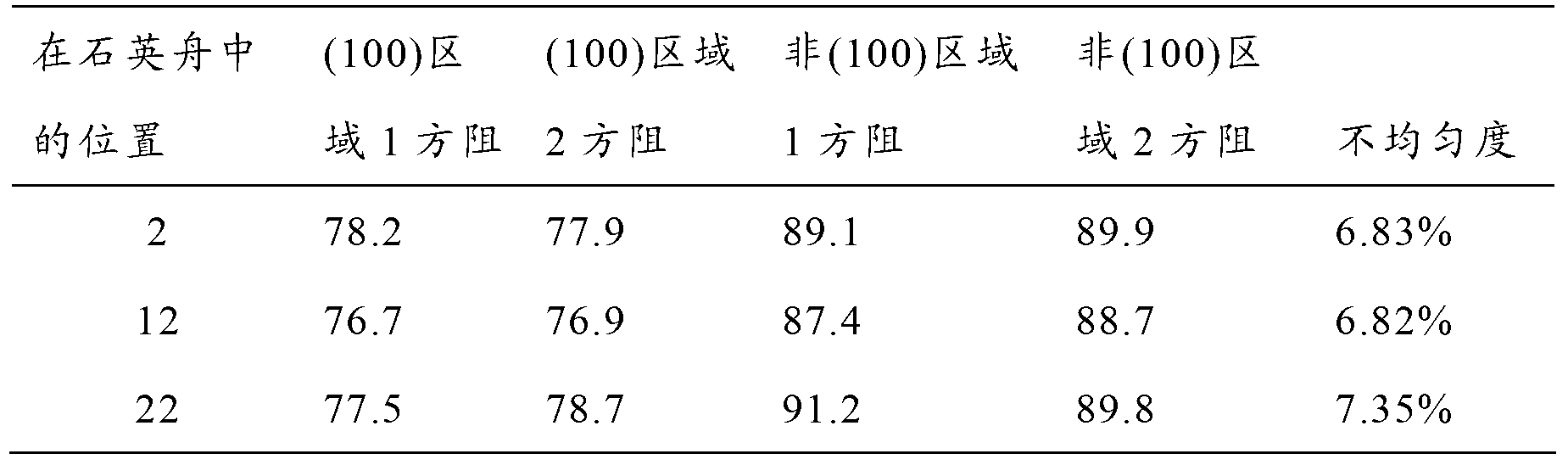

Embodiment 2

[0053] Put a set of P-type quasi-monocrystalline silicon wafers after texturing and cleaning into the diffusion furnace. In this embodiment, a set of P-type quasi-monocrystalline silicon wafers is specifically 25 pieces, which are carried by a quartz boat. Quasi-monocrystalline silicon wafers are processed as follows:

[0054] Adjust the temperature in the diffusion furnace to 750°C (ie the first temperature), and pretreat the P-type quasi-single crystal silicon wafers at a pressure of -100pa (first pressure). The processing time is preferably 5-10 minutes ;

[0055] Then increase the temperature to increase the temperature in the diffusion furnace to 750°C (the second temperature), and carry phosphorus oxychloride into the diffusion furnace by nitrogen at a pressure of -100 pa, keeping the flow rate of phosphorus oxychloride at 0.5 L / min, duration is 15 minutes;

[0056] Then lower the temperature, stop the introduction of phosphorus oxychloride, keep the temperature in the diffus...

Embodiment 3

[0068] Put a set of P-type quasi-monocrystalline silicon wafers after texturing and cleaning into the diffusion furnace. In this embodiment, a set of P-type quasi-monocrystalline silicon wafers is specifically 25 pieces, which are carried by a quartz boat. Quasi-monocrystalline silicon wafers are processed as follows:

[0069] Adjust the temperature in the diffusion furnace to 725°C (that is, the first temperature), and pretreat the P-type quasi-single crystal silicon wafers under a pressure of -75pa (first pressure). The processing time is preferably 5-10 minutes ;

[0070] Then increase the temperature to increase the temperature in the diffusion furnace to 775°C (the second temperature), and carry phosphorus oxychloride into the diffusion furnace by nitrogen at a pressure of -75pa, keeping the flow rate of phosphorus oxychloride at 0.75 L / min, duration is 12 minutes;

[0071] Then lower the temperature, stop the introduction of phosphorus oxychloride, keep the temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com