A relay bin system of a deep sea ore conveying device

A technology of conveying equipment and relay silo, which is applied in the mining of minerals, special mining, earth-moving drilling, etc., and can solve the problems of blocked nozzles and accumulated materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

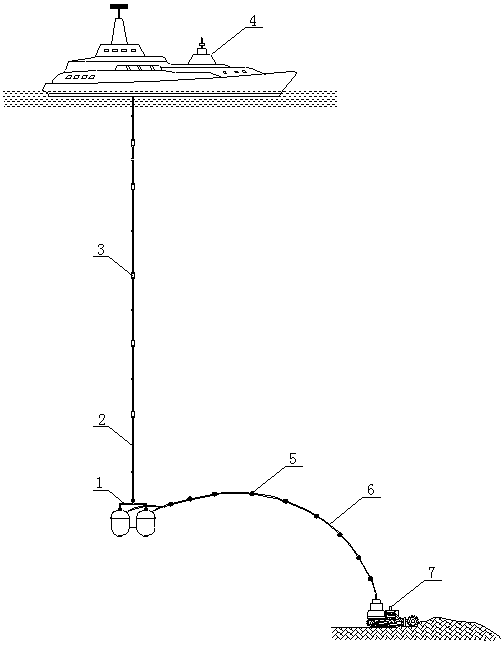

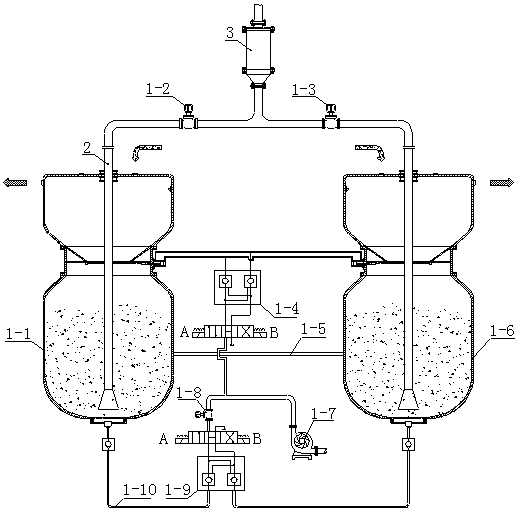

[0022] Such as Figure 1 to Figure 8 As shown, a deep-sea ore conveying equipment relay warehouse system is mainly composed of relay warehouse components (1) 1-1, electric control switch (1) 1-2, electric control switch (2) 1-3 , Pincer unloading device hydraulic control system 1-4, rigid support rod 1-5, relay warehouse assembly (2) 1-6, water pump 1-7, electric control switch (3) 1-8, jet hydraulic control system 1-9 and pipelines 1-10, etc., and the applicable mining system is mainly composed of lifting hard pipe 2, slurry pump 3, sea surface transport ship 4, buoyancy ball 5, slurry delivery hose 6 and ore collector 7 and so on.

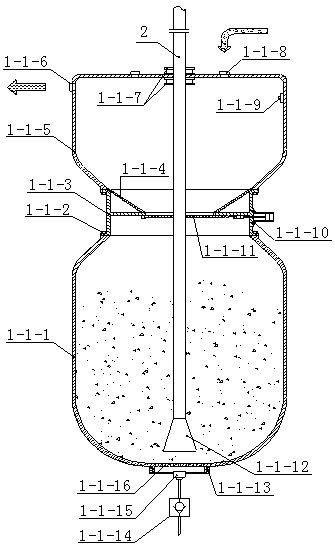

[0023] The relay warehouse assembly (1) 1-1 and the relay warehouse assembly (2) 1-6 contained in the relay warehouse system 1 have the same structure, and both are composed of the lower warehouse body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com