Electronic component hardness detection device

A technology for electronic components and testing devices, applied in measuring devices, testing material hardness, instruments, etc., can solve problems such as waste of manpower, deviations, omissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

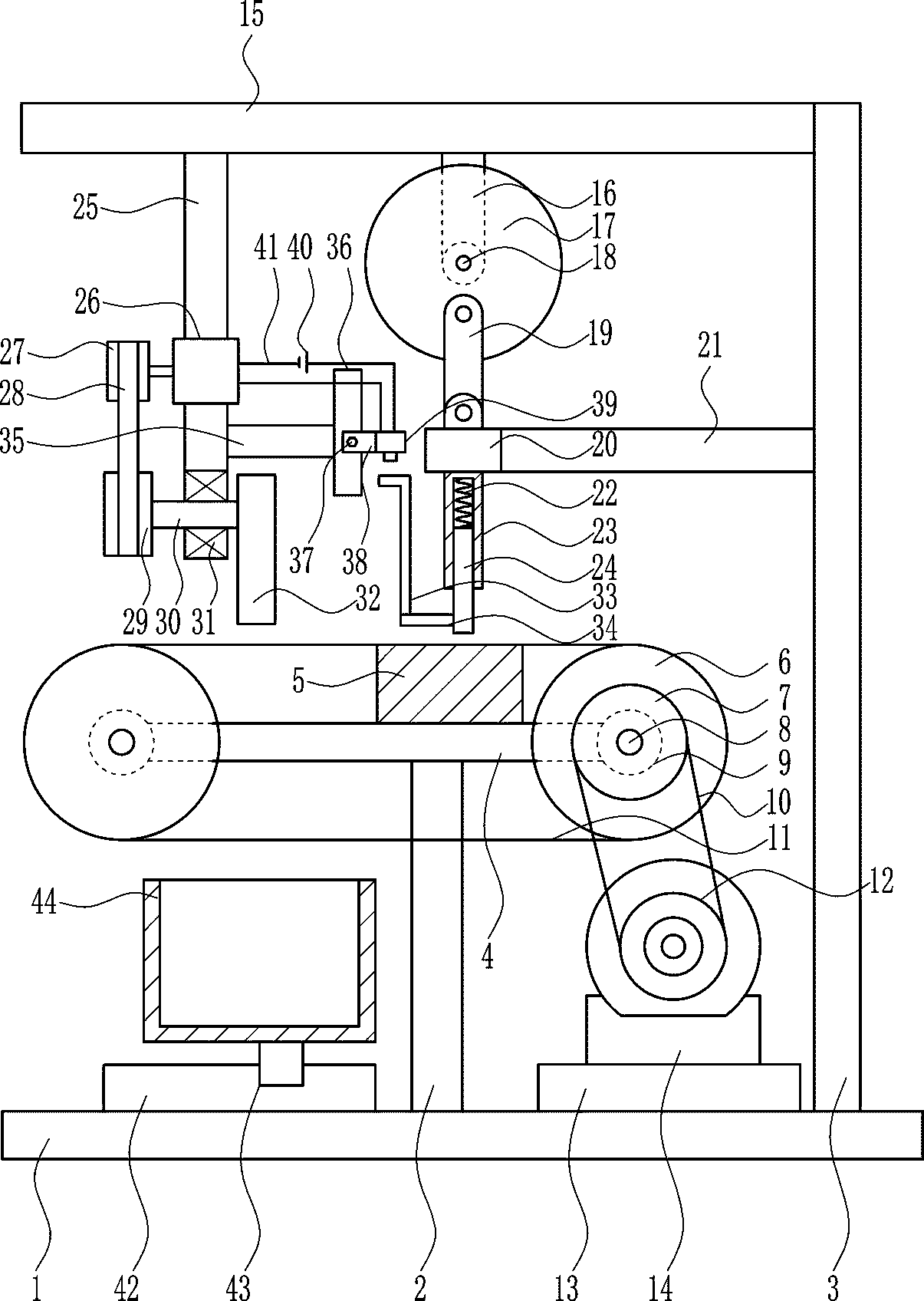

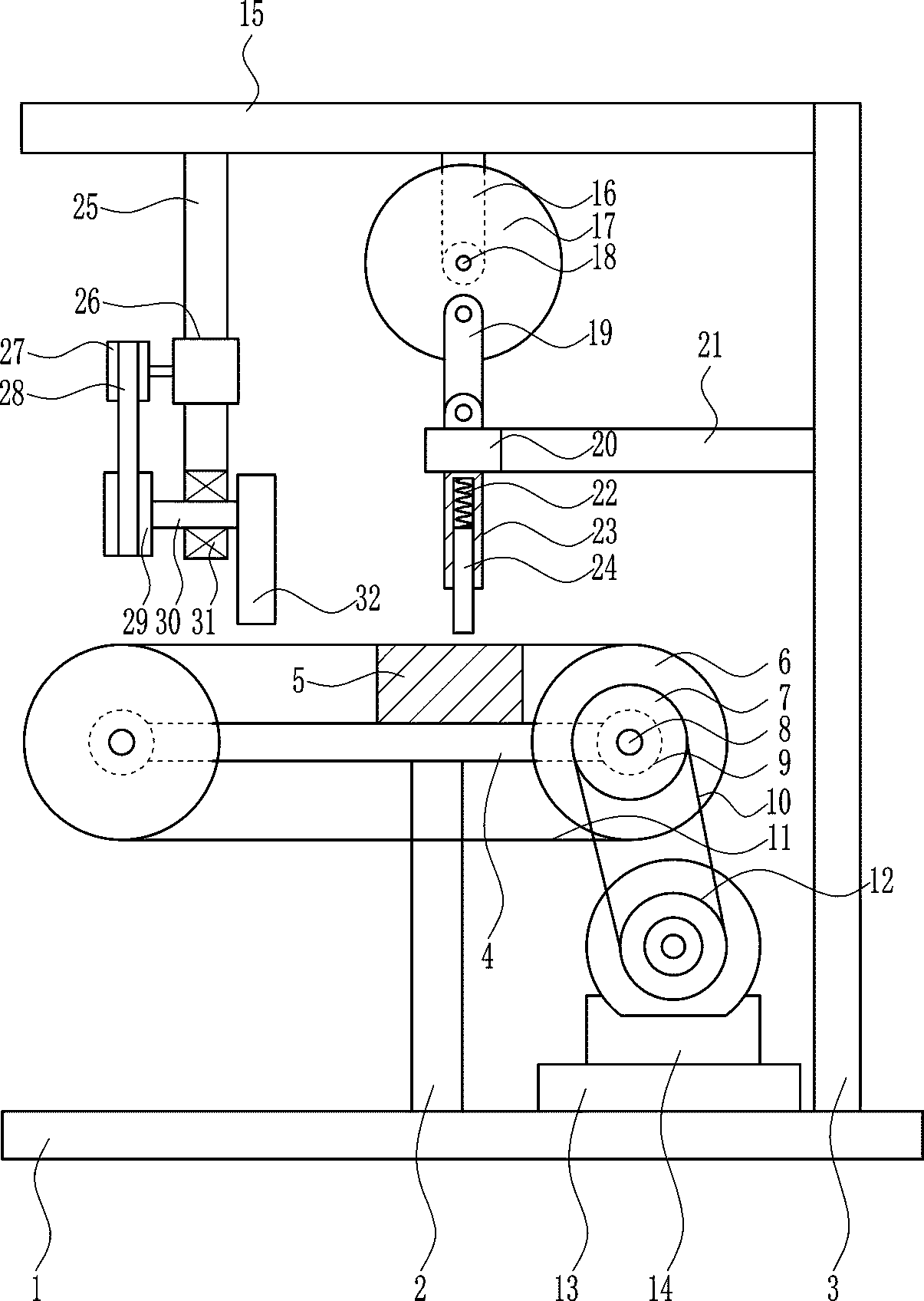

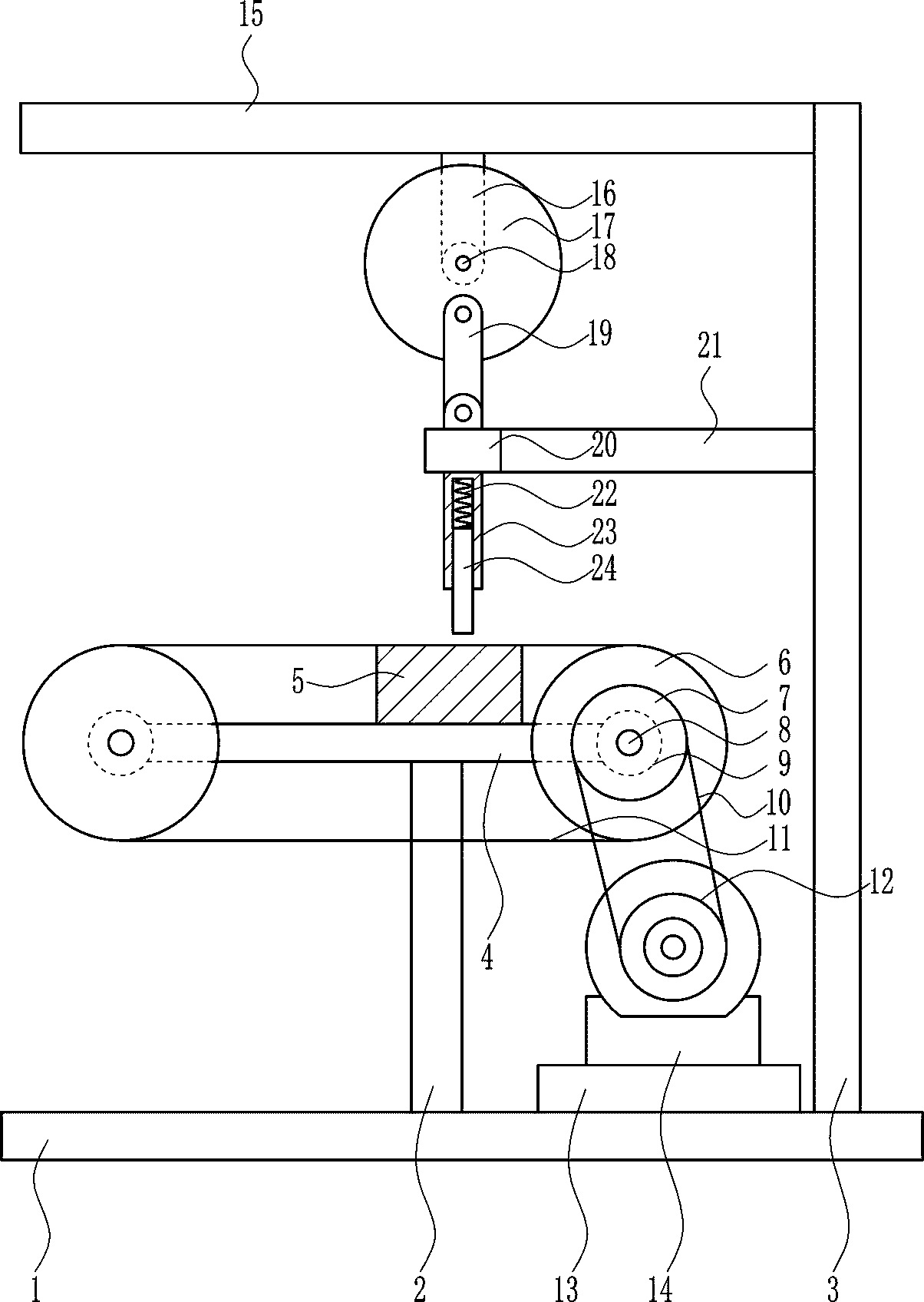

[0024] A device for testing hardness of electronic components, such as Figure 1-5 As shown, it includes a base 1, a first support rod 2, a second support rod 3, a third support rod 4, a pad 5, a transmission wheel 6, a first pulley 7, a first rotating shaft 8, a first bearing 9, a first One connecting belt 10, conveyor belt 11, second pulley 12, support platform 13, first motor 14, fourth support rod 15, fifth support rod 16, turntable 17, second motor 18, first connecting rod 19, sliding sleeve 20. The sixth support rod 21, the first spring 22, the second connecting rod 23 and the sliding rod 24. The upper part of the base 1 is sequentially installed with the first support rod 2, the support platform 13 and the second support rod 3 from left to right. A third support rod 4 is installed on the upper part of a support rod 2, and the third support rod 4 is symmetrically installed with a first bearing 9, and a first rotating shaft 8 is installed in the first bearing 9 through an...

Embodiment 2

[0026] A device for testing hardness of electronic components, such as Figure 1-5As shown, it includes a base 1, a first support rod 2, a second support rod 3, a third support rod 4, a pad 5, a transmission wheel 6, a first pulley 7, a first rotating shaft 8, a first bearing 9, a first One connecting belt 10, conveyor belt 11, second pulley 12, support platform 13, first motor 14, fourth support rod 15, fifth support rod 16, turntable 17, second motor 18, first connecting rod 19, sliding sleeve 20. The sixth support rod 21, the first spring 22, the second connecting rod 23 and the sliding rod 24. The upper part of the base 1 is sequentially installed with the first support rod 2, the support platform 13 and the second support rod 3 from left to right. A third support rod 4 is installed on the upper part of a support rod 2, and the third support rod 4 is symmetrically installed with a first bearing 9, and a first rotating shaft 8 is installed in the first bearing 9 through an ...

Embodiment 3

[0029] A device for testing hardness of electronic components, such as Figure 1-5 As shown, it includes a base 1, a first support rod 2, a second support rod 3, a third support rod 4, a pad 5, a transmission wheel 6, a first pulley 7, a first rotating shaft 8, a first bearing 9, a first One connecting belt 10, conveyor belt 11, second pulley 12, support platform 13, first motor 14, fourth support rod 15, fifth support rod 16, turntable 17, second motor 18, first connecting rod 19, sliding sleeve 20. The sixth support rod 21, the first spring 22, the second connecting rod 23 and the sliding rod 24. The upper part of the base 1 is sequentially installed with the first support rod 2, the support platform 13 and the second support rod 3 from left to right. A third support rod 4 is installed on the upper part of a support rod 2, and the third support rod 4 is symmetrically installed with a first bearing 9, and a first rotating shaft 8 is installed in the first bearing 9 through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com