Computer cooling system

A heat dissipation system and computer technology, applied in the computer field, can solve the problems of computer hardware failure, low heat dissipation efficiency, poor heat dissipation effect, etc., and achieve the effects of speeding up air flow, convenient disassembly and installation, and protection from dust infestation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

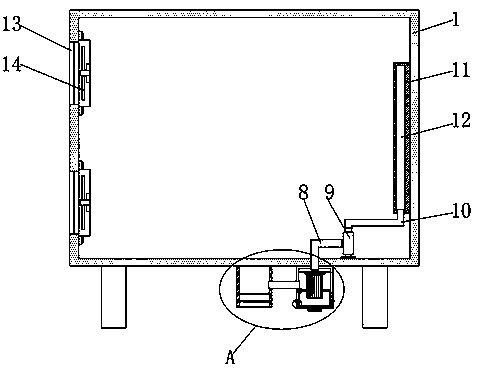

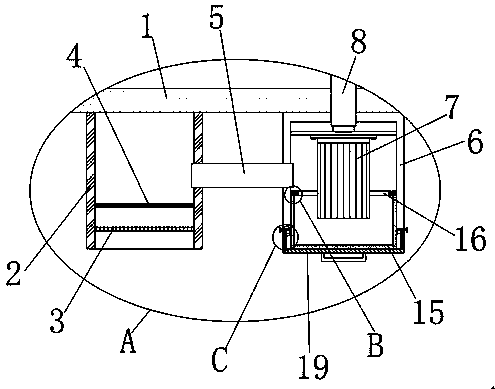

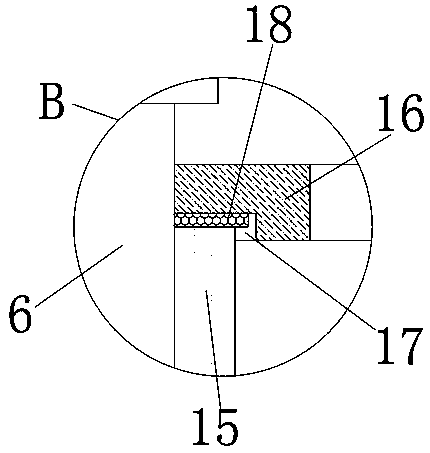

[0026] refer to Figure 1-Figure 6 As shown, a computer heat dissipation system is proposed in this embodiment, including a chassis 1, an air inlet tube 2 is fixedly installed at the bottom of the cabinet 1, and a coarse filter screen 3 and a first fine filter screen are fixedly installed on the inner wall of the air inlet tube 2 4. The first fine filter 4 is located above the coarse filter 3, and the bottom of the chassis 1 is located on one side of the air inlet tube 2. It is stipulated that a dust collection box 6 is installed, and the outer wall of one side of the air inlet tube 2 is fixed and connected. There is one end of the first air guide pipe 5, and the other end of the first air guide pipe 5 communicates with the dust collection box 6, the dust removal filter element 7 is fixedly installed in the dust collection box 6, and the negative pressure fan 9 is fixedly installed on the bottom inner wall of the chassis 1 The air inlet of the negative pressure fan 9 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com