A numerical prediction method for tip clearance cavitation of axial flow pump impeller

A blade tip clearance and numerical prediction technology, applied in CAD numerical modeling, image data processing, electrical digital data processing, etc., can solve the problem of low numerical prediction accuracy of vortex cavitation, achieve important theoretical value and engineering practical significance, The effect of improving credibility and clarifying principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

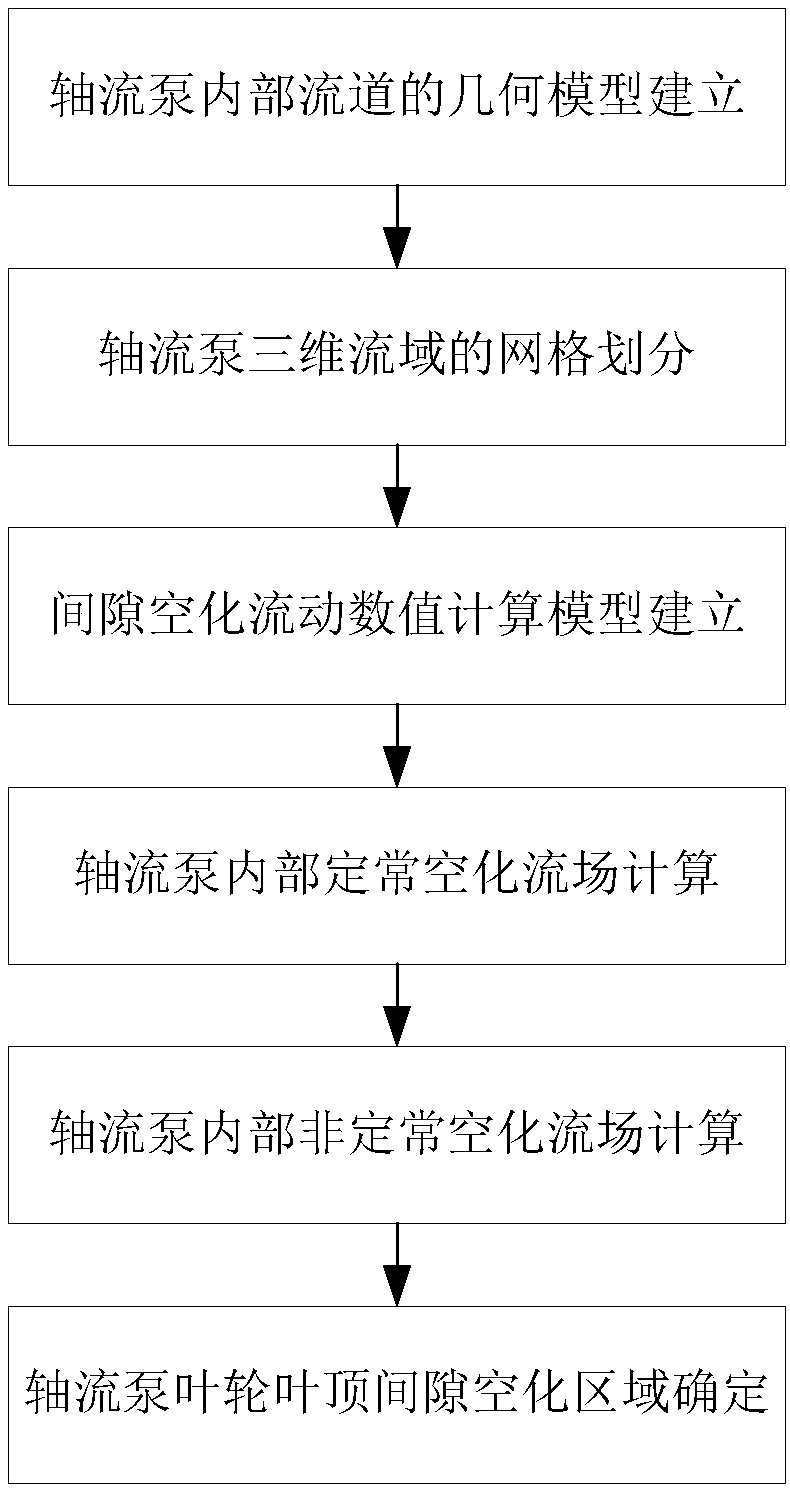

[0029] A numerical prediction method for the cavitation of the impeller tip clearance of an axial flow pump, the specific process is as follows figure 1 As shown, it is mainly realized by the following steps:

[0030] A. Establishment of the geometric model of the internal flow channel of the axial flow pump

[0031] According to the geometric parameters of an axial flow pump, the three-dimensional modeling software Unigraphics NX is used to establish the geometric model of the internal flow channel of the axial flow pump, including the inlet flow channel, impeller flow channel, guide vane flow channel and water outlet flow channel; In the geometric model of the impeller, the width of the impeller tip clearance is 1.6 thousandths of the diameter of the runner.

[0032] B. Mesh division of three-dimensional flow domain of axial flow pump

[0033] Import the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com