Horizontal support structure for multi-vessel system

A horizontal support and multi-vessel technology, applied in the field of nuclear power, can solve the problems of increasing the supporting bending moment, stress, and fatigue at the lower part of the vessel, and achieve the effect of simple and effective layout and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

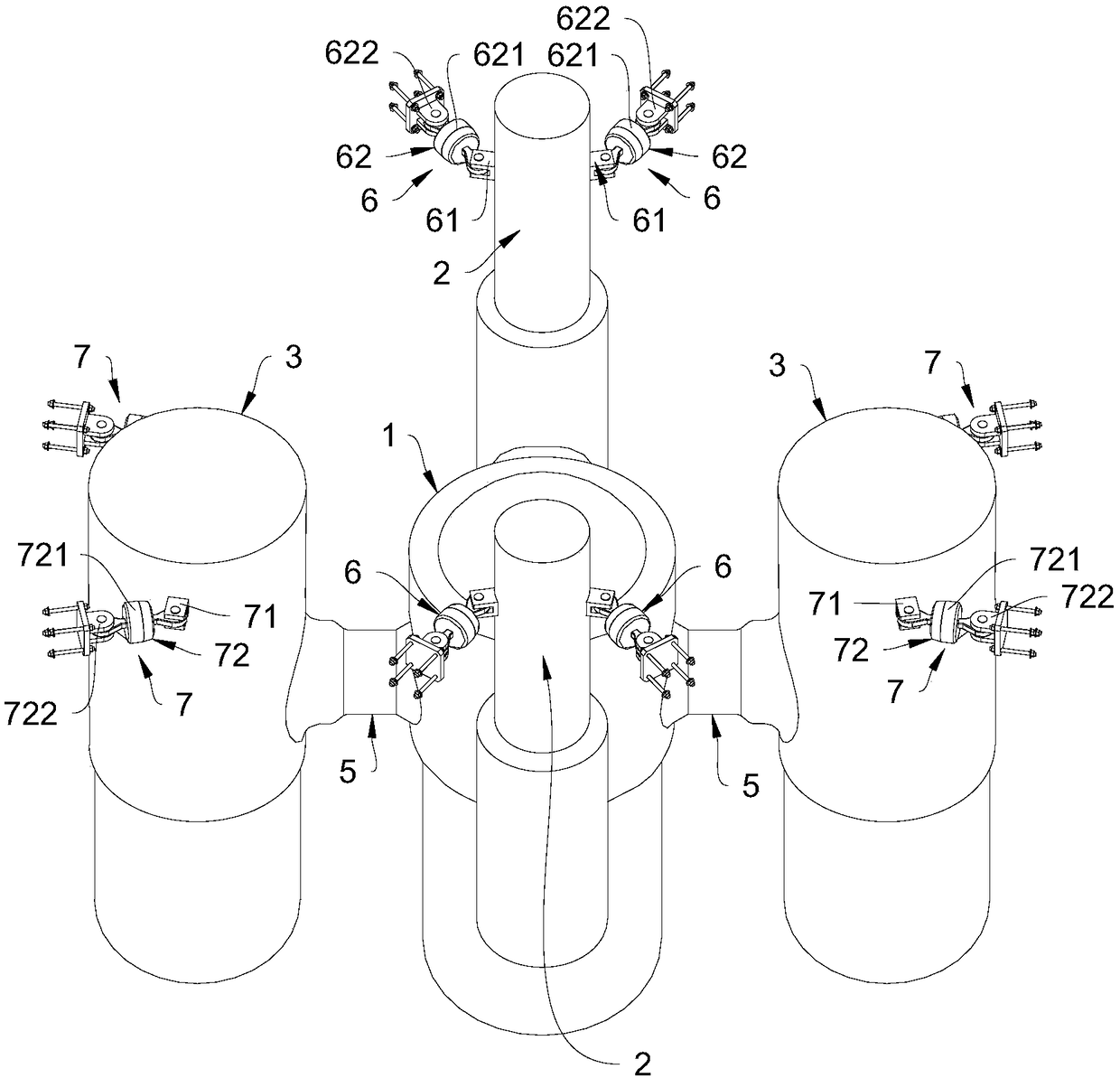

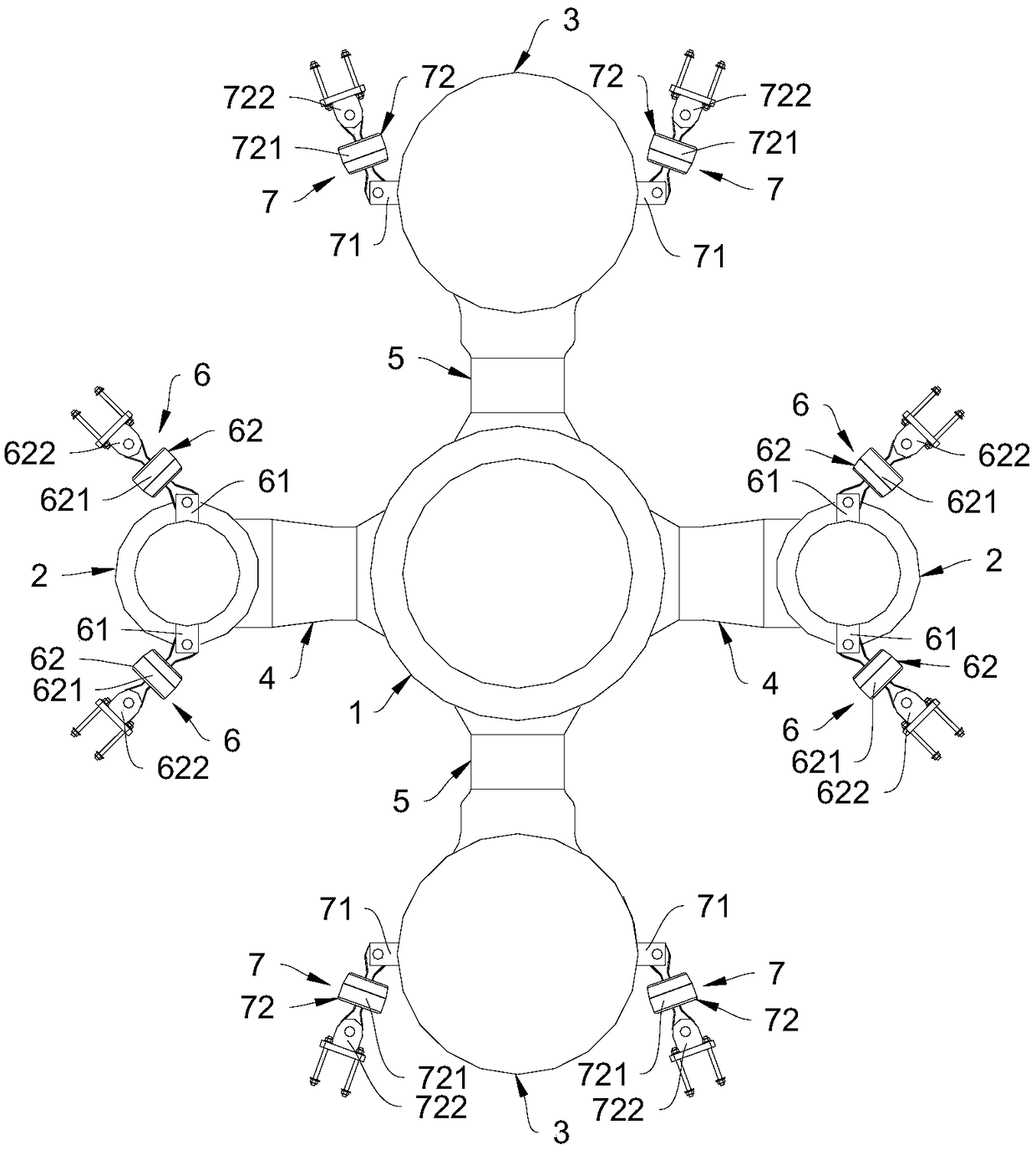

[0027] Such as figure 1 , figure 2 As shown, the multi-container system in a preferred embodiment of the present invention includes main equipment containers such as a pressure vessel 1, a steam generator 2, and a main pump 3. The steam generator 2 and the main pump 3 include two respectively, and two steam generators 2 and two main pumps 3 are respectively center-symmetrically arranged on the circumference of the pressure vessel 1, and the steam generator 2 and the main pump 3 are alternately arranged on the circumference of the pressure vessel 1 and evenly spaced around the circumference of the pressure vessel 1.

[0028] The steam generator 2 is connected to the pressure vessel 1 through the first pipeline 4 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com