A large tonnage multi-channel optical fiber composite insulator

An optical fiber composite and multi-channel technology, applied in the field of power transmission and transformation, can solve the problems of difficulty in ensuring the quality of UHV fiber composite insulators, long length of fiber optic composite insulators, and low work efficiency, so as to reduce the lightning tripping rate and improve performance. The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

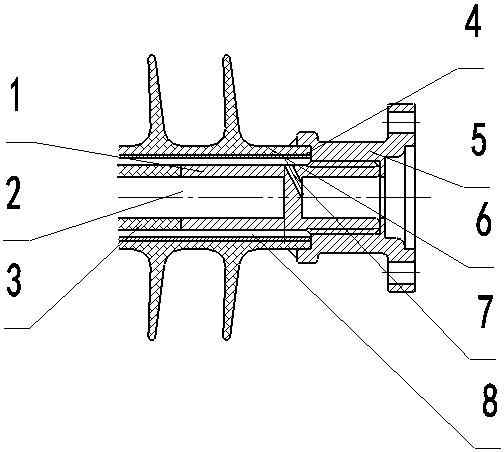

[0019] figure 1 In the middle, the end of the connecting fitting 1 is crimped to the mandrel 2, and the external fitting 5 is connected to the connecting fitting 1 with a thread. Before the installation process, apply epoxy resin on the screw rod (for sealing function), and the unpressed part of the mandrel 2 Wipe it with alcohol first, then wrap it with a silicone rubber tape, connect the crimped end of the metal fitting 1 and the mandrel 2 and wrap the silicone rubber tape with an epoxy cylinder 4, and inject a silicone rubber umbrella skirt 6 outside the epoxy cylinder 4. 6 is formed by arranging the umbrella skirt groups of multiple periods in sequence, and the umbrella skirt groups of each period include a large umbrella skirt and a small umbrella skirt. The two ends of the epoxy cylinder 4 have outer wires, and the outer metal fittings 5 have inner wires. The end of the epoxy cylinder 4 is threadedly connected with the outer metal fittings 5, and the interface is seale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com