Enhanced immersion cooling with flow diversion

A cooling device and immersion technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as heat source temperature soaring, chip burning, heat transfer deterioration, etc., to avoid gas-liquid retrograde, enhance supply The effect of liquid flow and enhanced heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

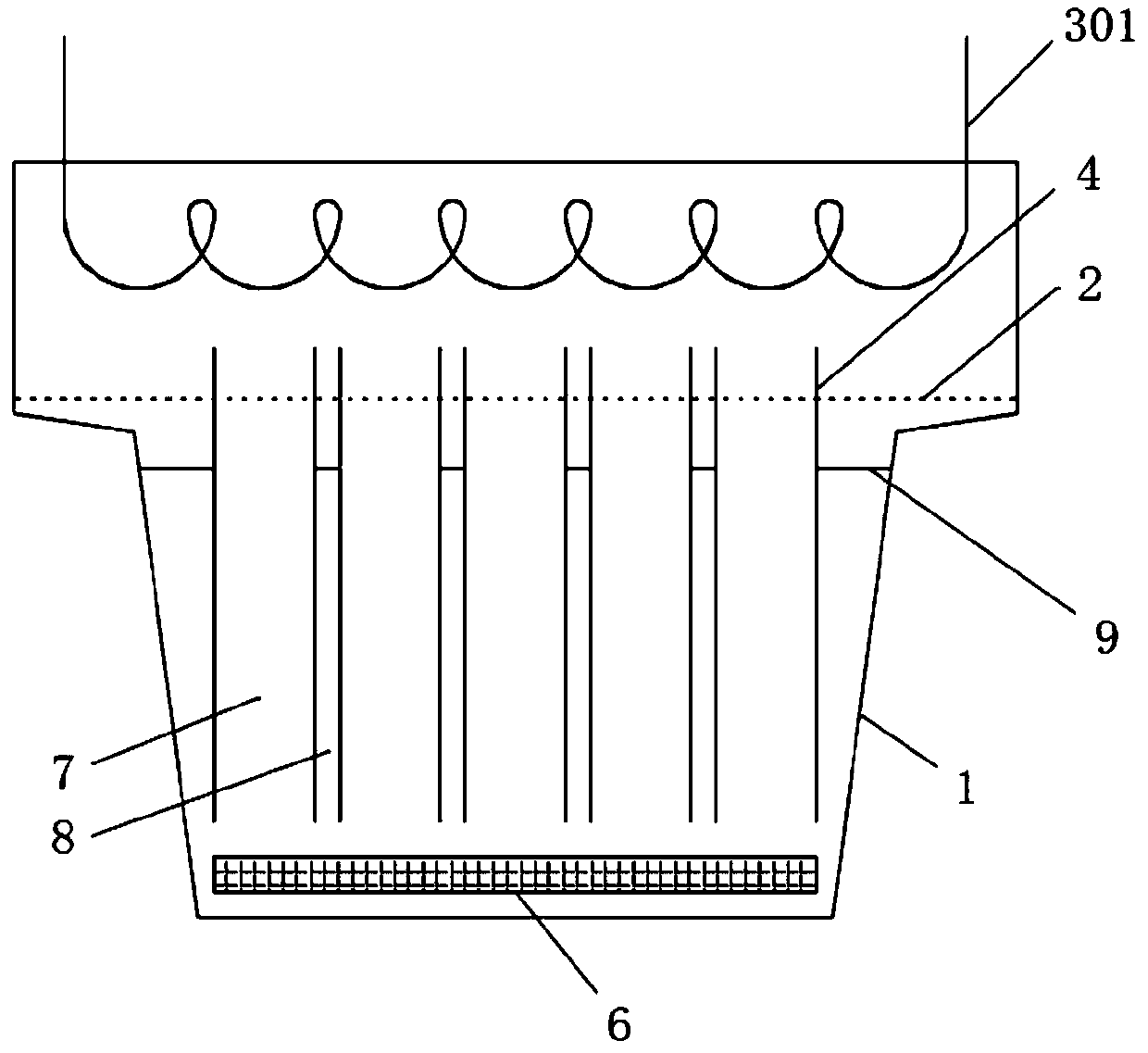

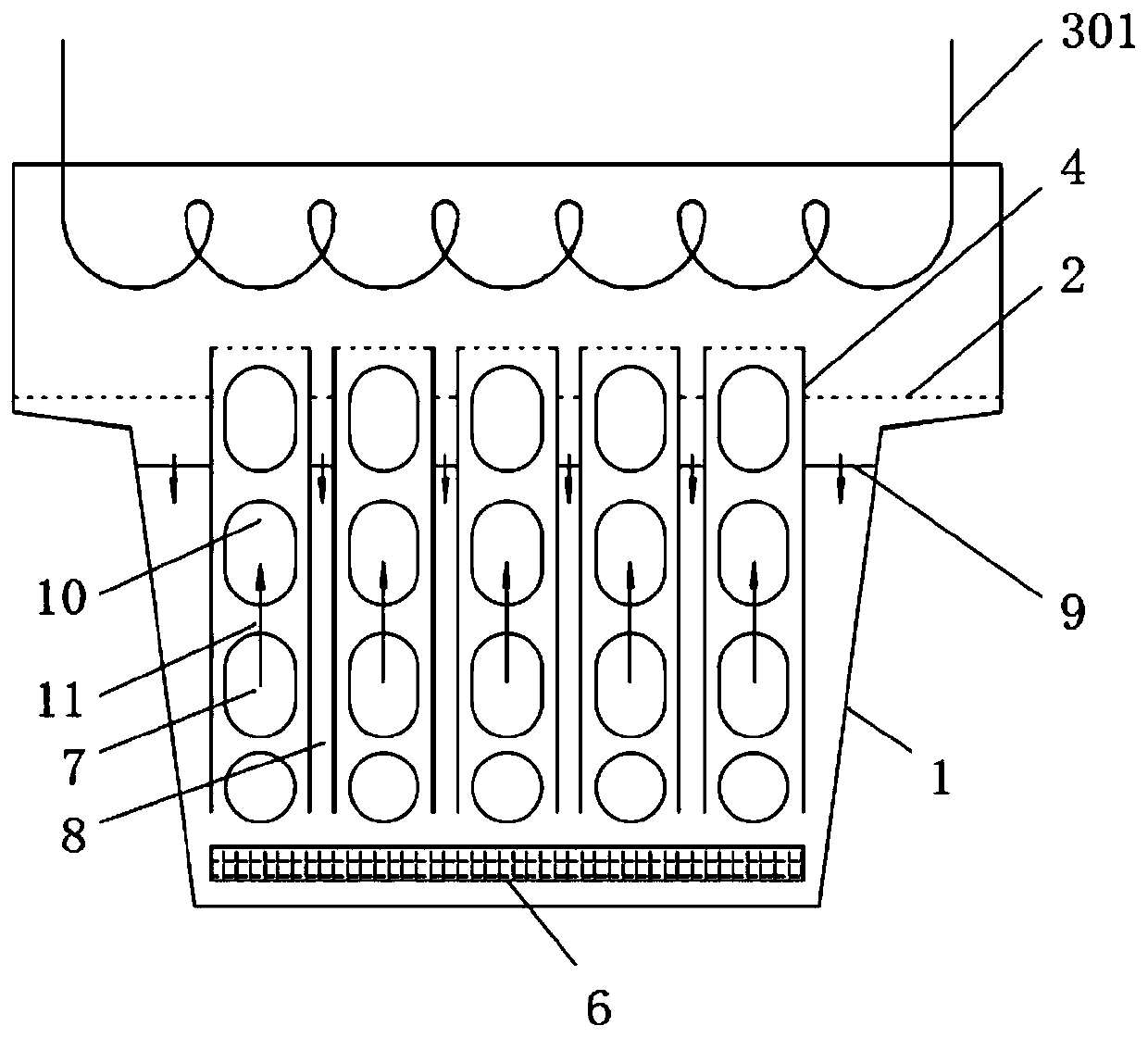

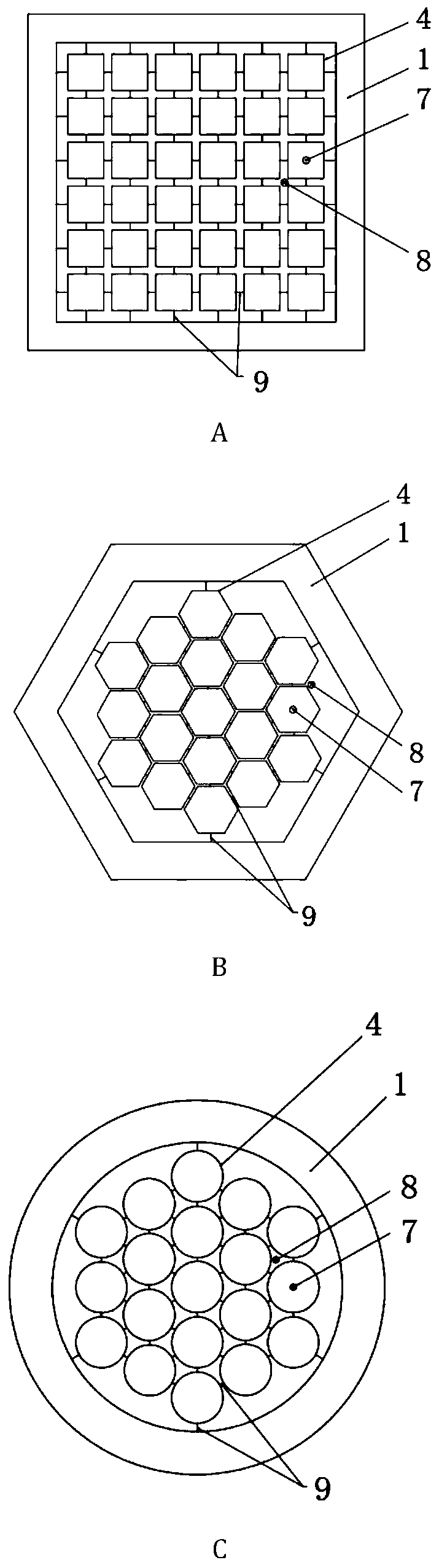

[0023] Such as figure 1 and figure 2 As shown, this embodiment includes: a housing 1, an insulating working medium 2, a condensing device, a deflector 4 and a component to be cooled 6, wherein: the component to be cooled 6 as a heat source and the condensing device as a cold source are respectively connected to the housing 1 connected, the deflector 4 is vertically arranged in the housing 1 and is not in contact with the heat source and the cold source, the ascending passage 7 and the return passage 8 of the insulating working fluid are formed between adjacent deflecting plates 4, and the insulating working fluid 2 It flows through the ascending channel 7 and the return channel 8 in the housing 1, forming a directional circulation in a closed space.

[0024] The housing 1 is made of aluminum alloy with high thermal conductivity.

[0025] The insulating working medium 2 is adopted but not limited to hydrofluoroether, preferably hydrofluoroether HFE7000.

[0026] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com