Low-flow-resistance aviation liquid cooling case

A liquid cooling machine, low flow resistance technology, applied in cooling/ventilation/heating transformation, electrical components, sealed enclosures, etc., can solve the problems of aggravating temperature unevenness, large flow resistance of the chassis, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

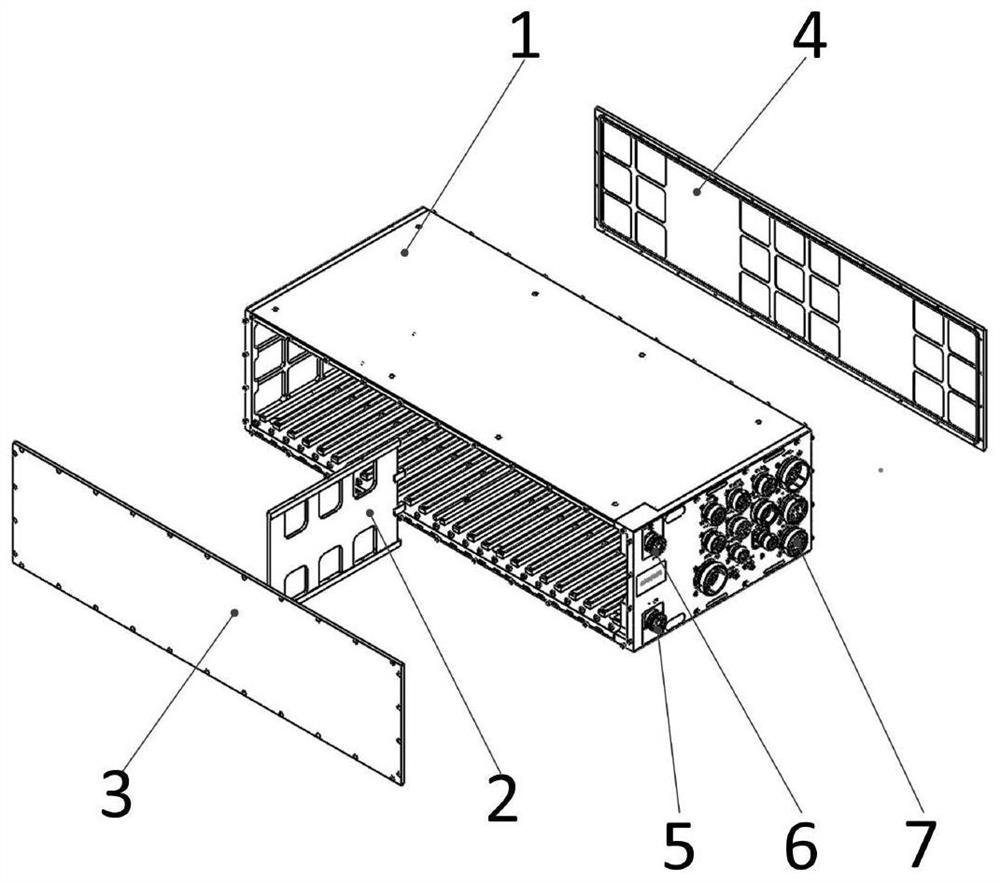

[0027] like figure 1 and 2 As shown, a low-resistance aviation liquid-cooled chassis includes a chassis frame 1 , a support plate 2 , a front panel 3 , a rear panel 4 , an inlet fluid connector 5 , an outlet fluid connector 6 , and an electrical connector 7 .

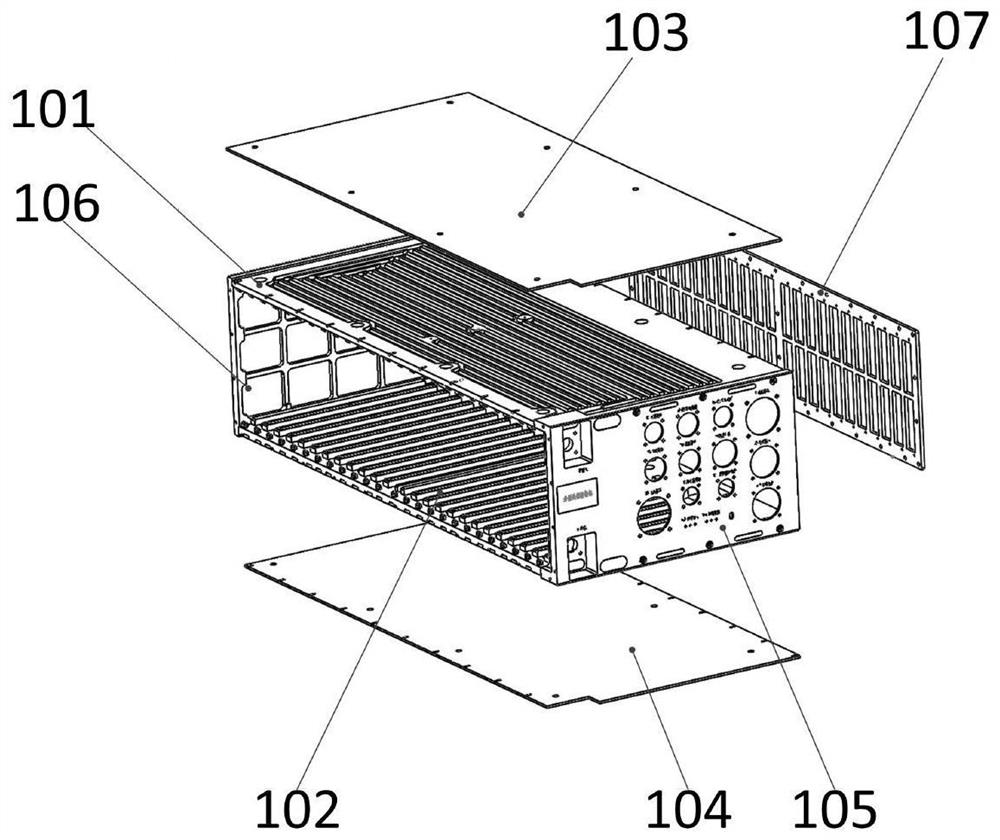

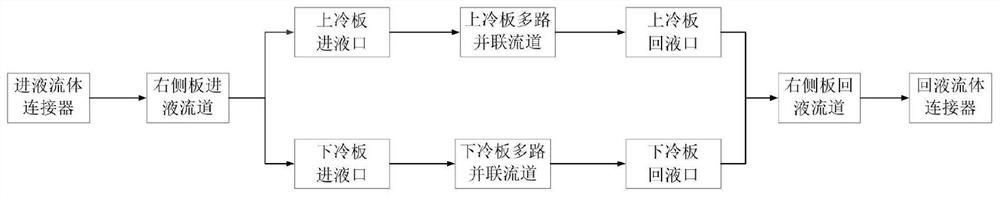

[0028] Wherein, the chassis frame includes an upper cold plate 101, a lower cold plate 102, an upper cold plate cover plate 103, a lower cold plate cover plate 104, a right panel 105, a left panel 106 and a back plate fixing plate 107; There are closed flow passages communicating with each other in the right panel;

[0029] The support plate is respectively fixed with the upper cold plate and the lower cold plate of the chassis frame by screws to play a supporting role and prevent the deformation of the chassis frame; The sealing rubber strip ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com