Pouring element for a composite packaging and a composite packaging comprising a pouring element

A technology of composite packaging and components, applied in packaging, transportation and packaging, closing, etc., can solve problems such as high cost and complicated manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

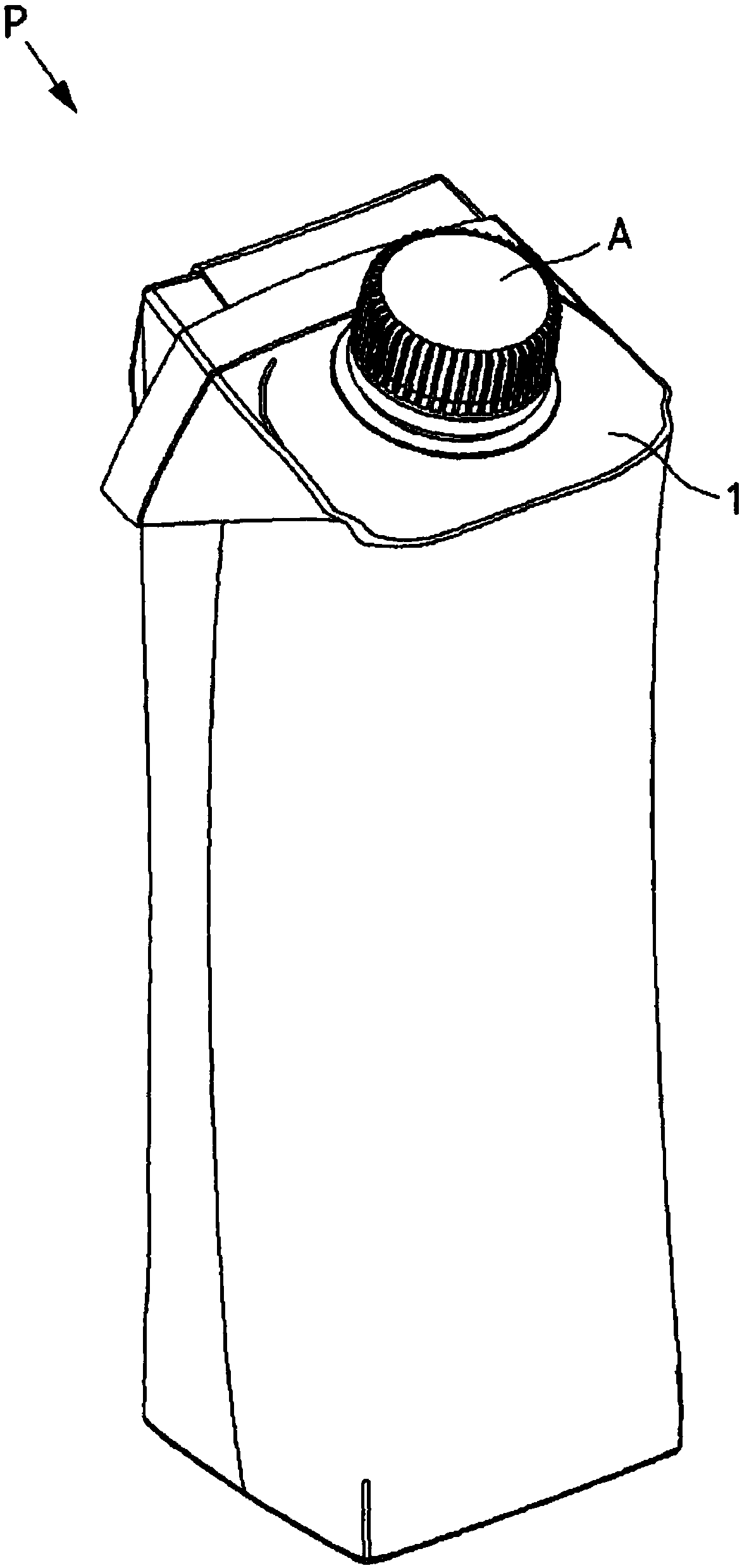

[0034] figure 1 The embodiment of the composite package P according to the invention shown in the package P shown is a beverage box. The composite package P consists of a packaging material consisting of a series of flat joined together materials forming a packaging laminate: a polymer layer is laminated on both sides of a carton carrier layer and an additional layer of aluminum The products inside the composite package P are shielded from undesired environmental influences (light, oxygen).

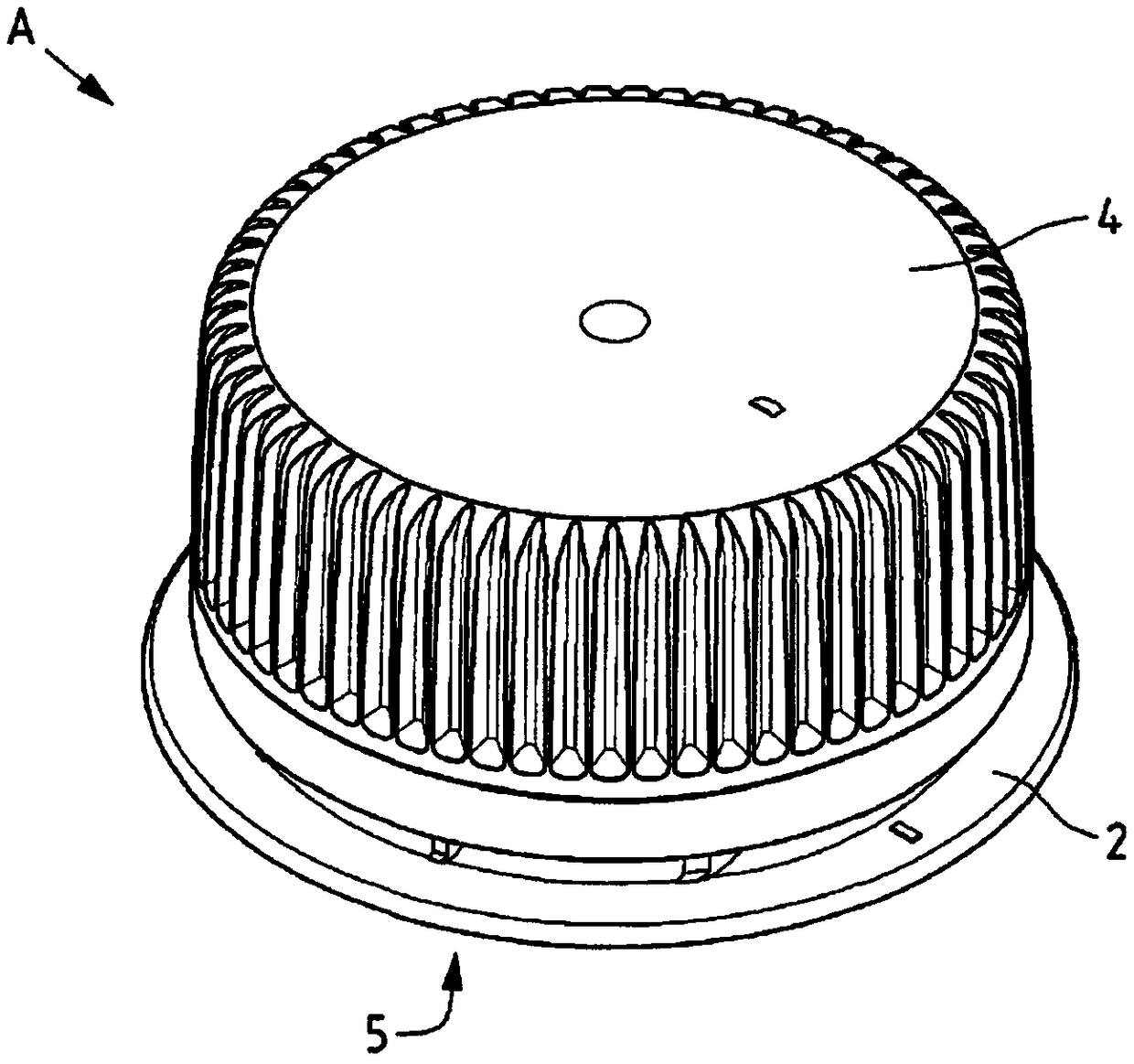

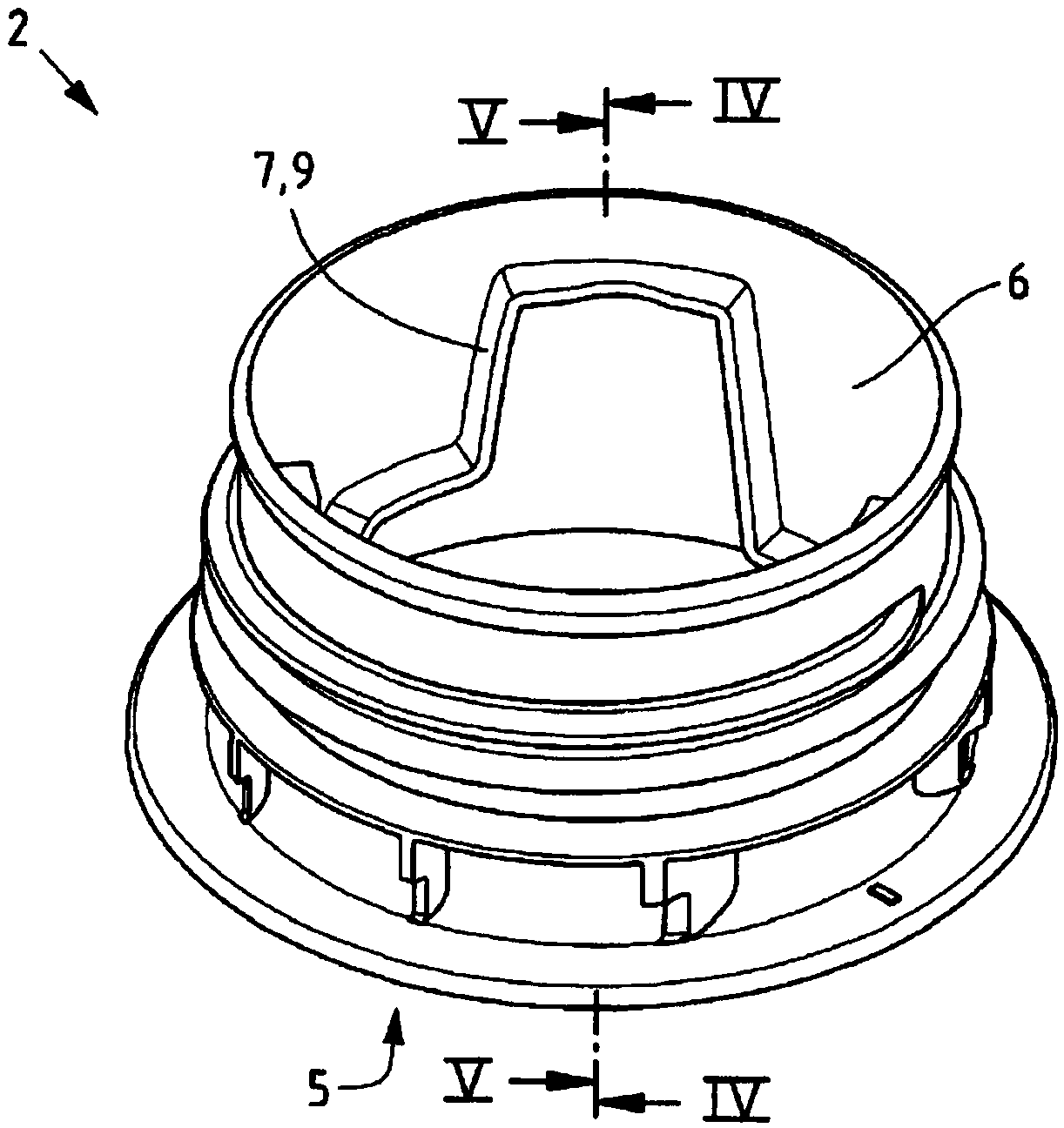

[0035] The composite package P has in the edge region a package gable panel 1 to which the pouring element A according to the invention is also applied and permanently attached. When the pouring element A is actuated for the first time, the weakened area of the packaging material (here covered by the pouring element A) is severed and thus the composite package P is opened for the first time and is then ready for pouring out the contents. This area of weakness in the illustrated and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com