Comb honey production assembly and using method thereof

A technology for nest honey and components, applied in the field of bee breeding, can solve the problems of inconvenience to eat, easy to cause pollution, pollution of nest honey, etc., and achieve the effect of improving sales and edible value, simplifying production process, and promoting development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

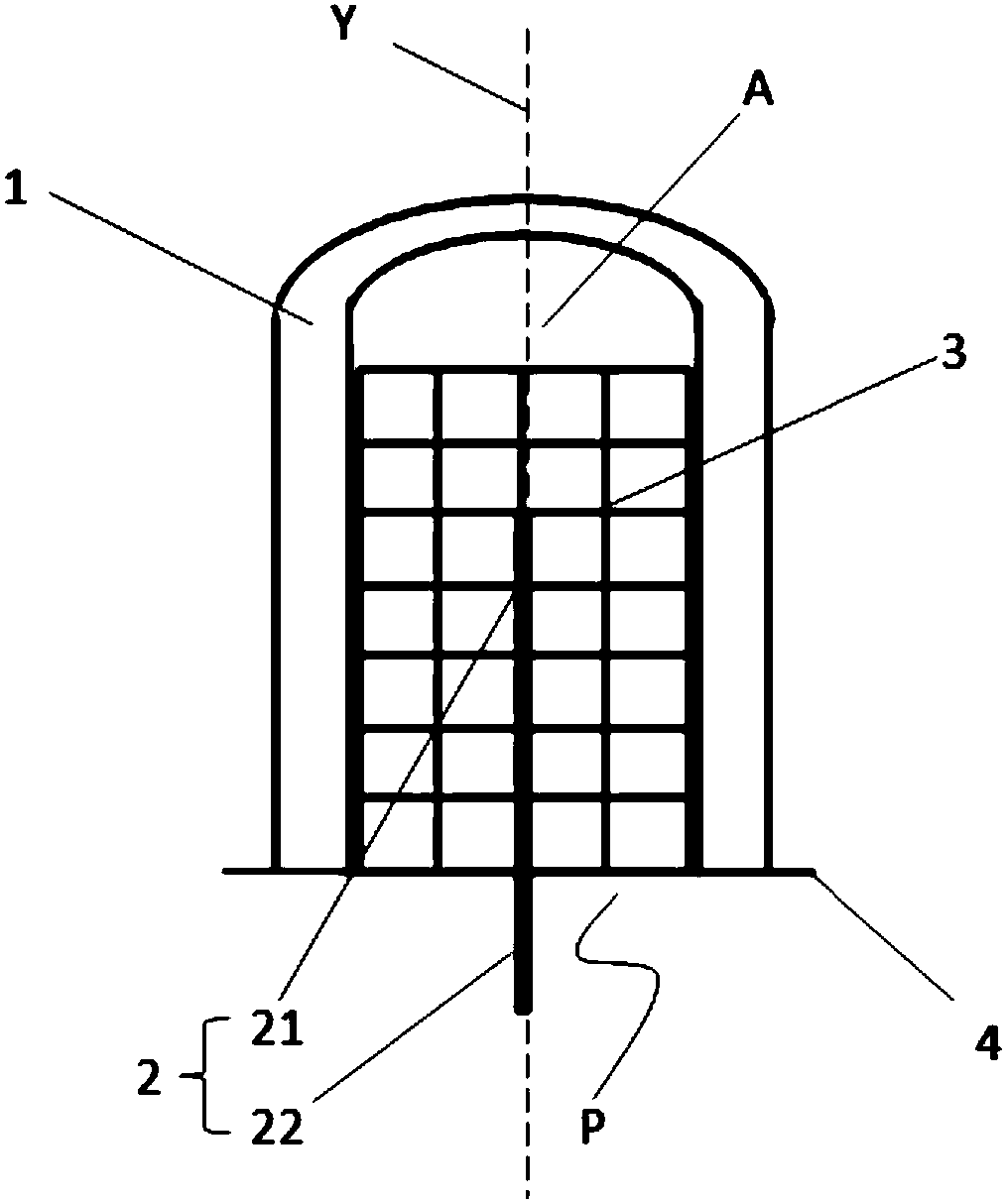

[0043] Such as figure 1 As shown, the honeycomb production assembly in the present invention includes: a honeycomb production part 1 with an upper opening P, a handle 2, and a honeycomb foundation 3; the honeycomb production part 1 has an internal space for accommodating the honeycomb foundation 3 A; one end 21 of the handle 2 extends into the inner space A, and is fixedly connected with the nest foundation 3 in the inner space A, and the other end 22 of the handle 2 is along the honeycomb production part The vertical central axis Y of 1 extends to the outside of the inner space A; the base 3 can be made of pure beeswax, which is used for honeybees to build a honeycomb and store honey to form the honeycomb, and preferably, the There is clearance fit between the nest foundation 3 and the honey comb production part 1 .

[0044] On this basis, the honeycomb production assembly further includes a baffle 4, which is detachably connected to the honeycomb production part, and is use...

Embodiment 2

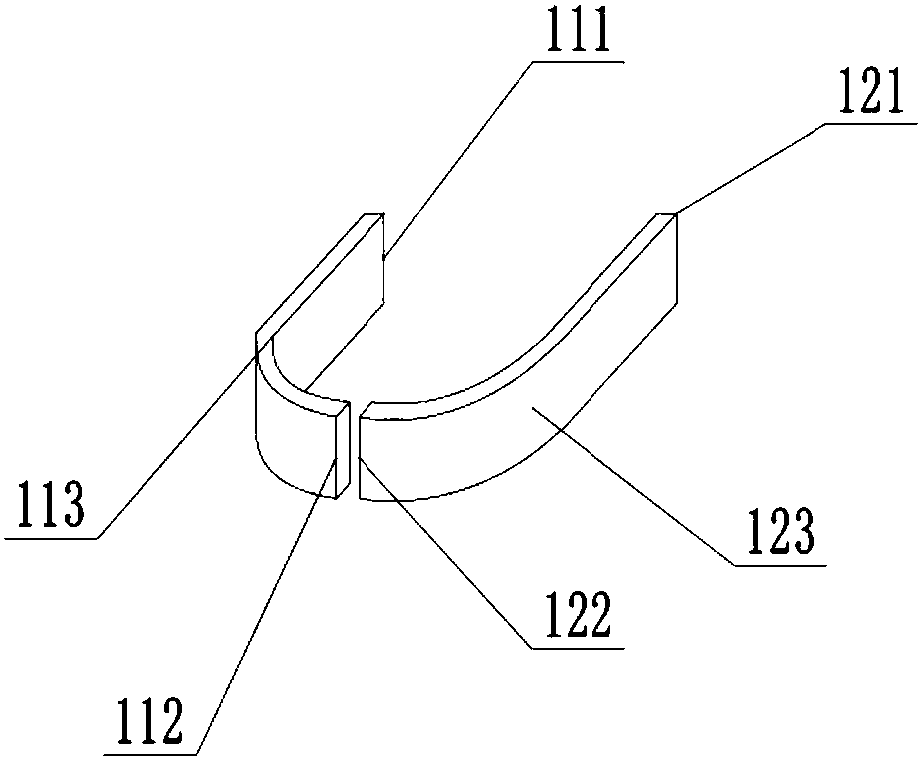

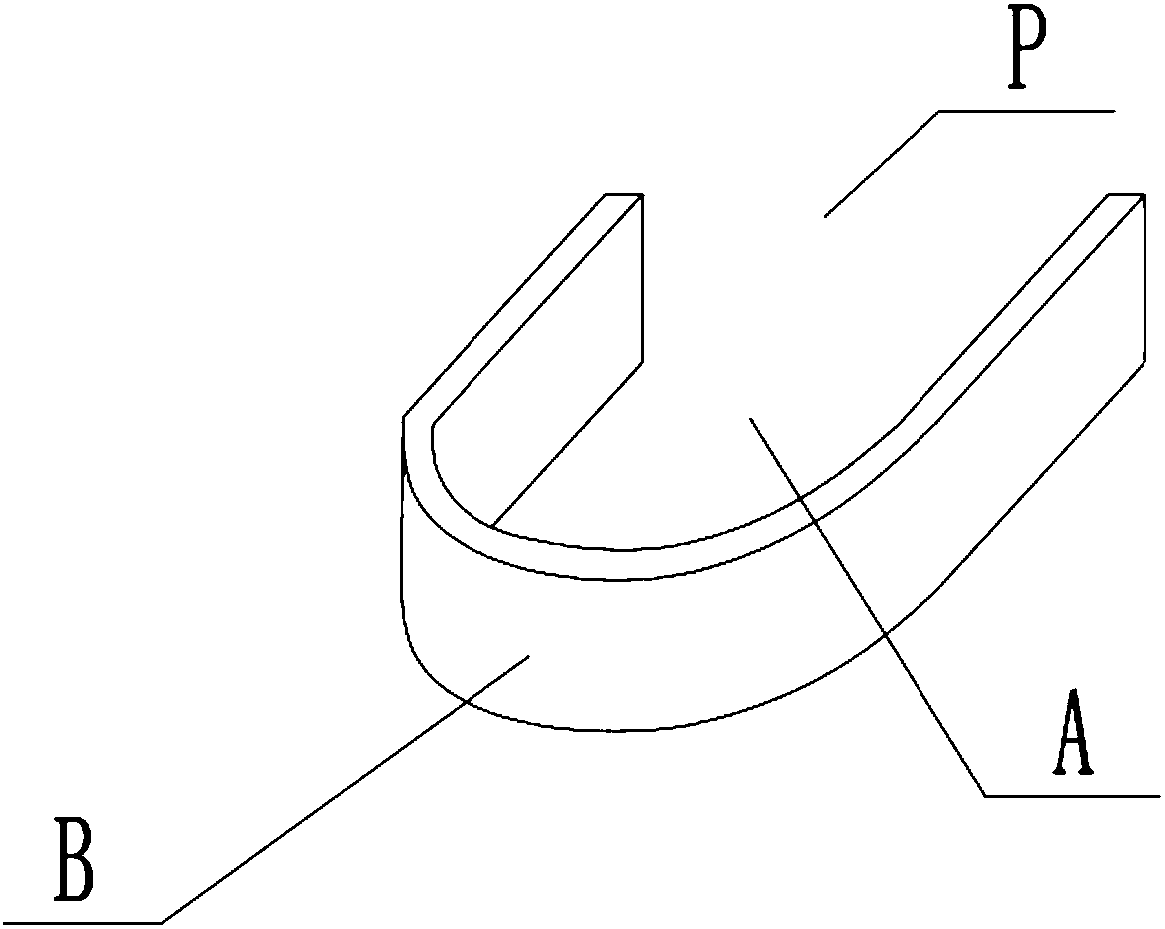

[0055] Such as Figures 5a-5b As shown, the difference between the present embodiment and the first embodiment is that the honeycomb production unit 1 includes:

[0056] The first half-tube body 100 and the second half-tube body 101 detachably connected to the first half-tube body 100 (such as clamping, buckling, etc.), and through the first half-tube body 100 and the The second half pipe body 101 is detachably connected to form the inner space A, the upper opening P and the bottom opening B' for the bees to enter the inner space, the upper opening P and the bottom opening B' mutually connected. The first half-pipe body 100 and the second half-pipe body 101 can be semi-circular pipes or semi-square pipes, and the honeycomb production part 1 thus constituted can be round pipes or square pipes. And the inner wall of the first half-pipe body 100 and / or the second half-pipe body 101 is provided with a groove 13 .

[0057] And similarly, the outer wall of the first half-pipe bod...

Embodiment 3

[0062] On the other hand, the present invention also provides a method for using the above-mentioned honeycomb production component, which includes the following steps:

[0063] S1. Put the honeycomb production component into the bee colony, and make the other end of the handle extending outside the inner space face up;

[0064] S2. Reward feeding the bee colony on the same day, and regularly supplementing young bees, so that the bees build honeycombs and store honey in the honeycomb production component to produce honeycomb;

[0065] S3. Unloading the honeycomb production assembly, wrapping the entire honeycomb with the paper layer, and refrigerating the wrapped honeycomb together with the honeycomb production assembly;

[0066] Or separate the honeycomb production part from the paper layer, wrap the whole honeycomb with the paper layer, and refrigerate the wrapped honeycomb separately.

[0067] Preferably, the following steps are also included:

[0068] S4. Take out the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com