Hydraulic gas compression purification system and compression purification method thereof

A gas compression and purification system technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large flow changes and unseen problems, and achieve strict control logic, ingenious design, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

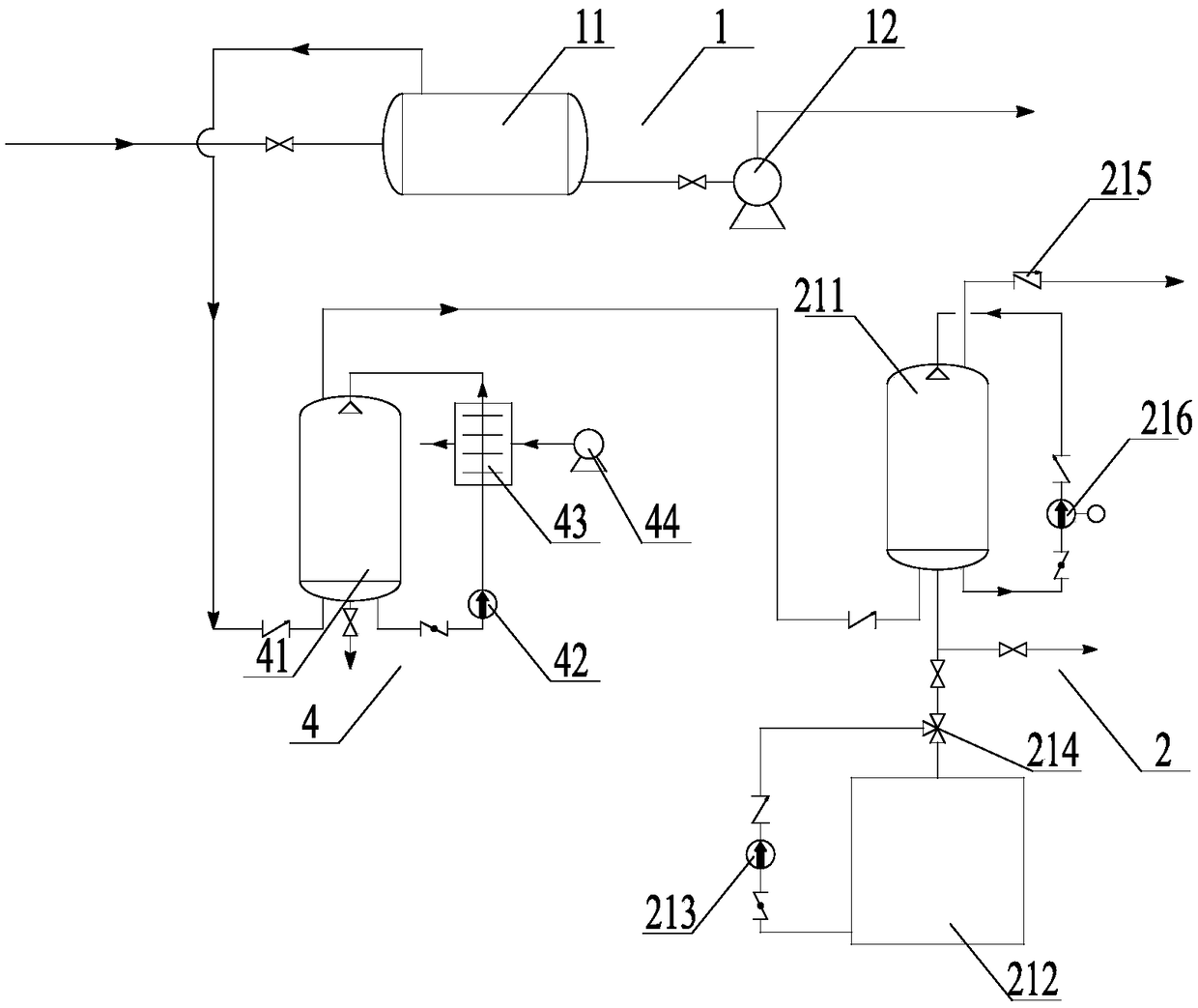

[0047] Such as figure 1As shown, Embodiment 1 of the present invention provides a hydraulic gas compression and purification system, including: a gas-liquid separation assembly 1 , a purification compression assembly 2 , an automatic control assembly and a cooling separation system 4 .

[0048] The gas-liquid separation assembly 1 is used to carry out gas-liquid separation treatment on the incoming liquid containing gas, and the gas outlet end of the gas-liquid separation assembly 1 is connected to the inlet end of the cooling separation system 4 through a pipeline; the cooling separation system 4 For removing liquid droplets and steam in the gas, the outlet end of the cooling separation system 4 is connected to the inlet end of the purification compression assembly 2 through a pipeline; the purification compression assembly 2 is used for compressing and purifying the gas; the The automatic control component is electrically connected with the gas-liquid separation component 1 ...

Embodiment 2

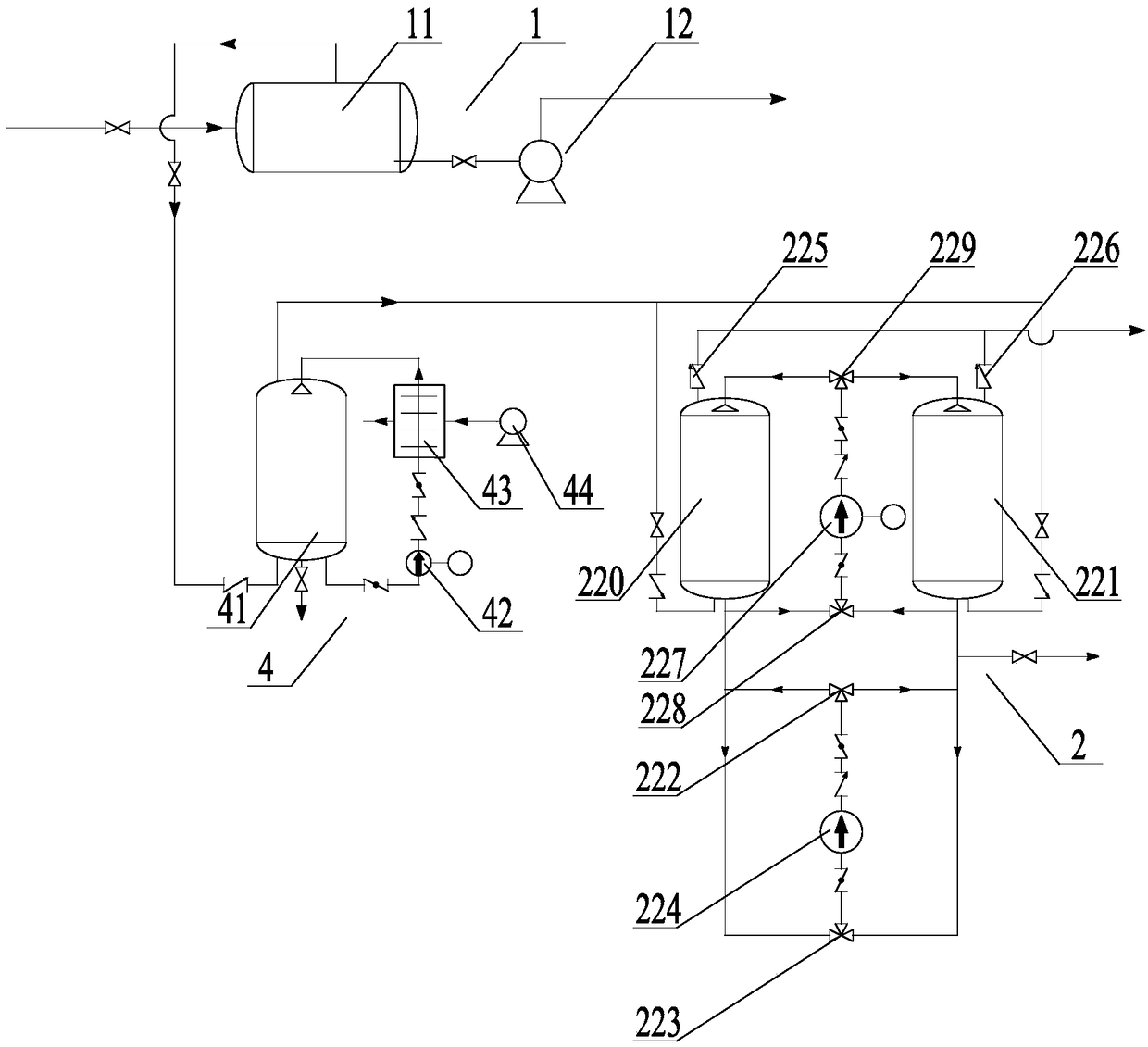

[0068] Such as figure 2 As shown, Embodiment 2 of the present invention provides a hydraulic gas compression purification system, which is similar to the hydraulic gas compression purification system provided in Embodiment 1, including: gas-liquid separation assembly 1, purification compression assembly 2, automatic control Components and cooling separation system4.

[0069] Wherein, the structure, connection mode and operation mode of the gas-liquid separation assembly 1 , the automatic control assembly and the cooling separation system 4 are similar to those in Embodiment 1, and will not be repeated here.

[0070] The difference is that the purification compression assembly 2 includes a first purification compression tank 220, a second purification compression tank 221, a first electric three-way valve 222, a second electric three-way valve 223, a first compression pump 224, a first row Air control valve 225 and second exhaust control valve 226.

[0071] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com