Tea leaf soaking, cleaning, drying and sterilizing treatment system

A processing system and drying technology, which are used in tea processing before extraction, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of no sterilization treatment function, increase equipment cost, high labor intensity, etc., and reduce labor intensity. , Save the cost of use, the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

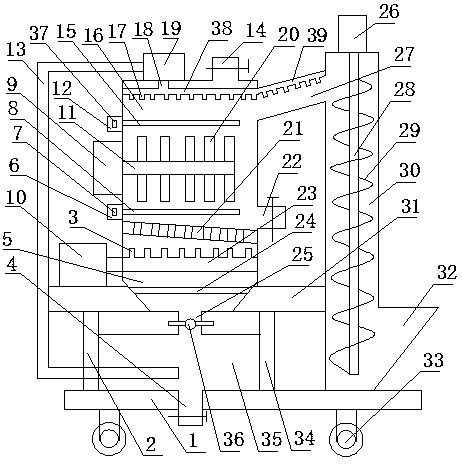

[0019] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

[0020] Such as figure 1 The shown tea soaking, cleaning, drying and sterilization treatment system includes an installation base 1, and the upper part of the installation base 1 is fixedly installed with a left support column 2, a liquid collection chamber 35, a right support column 34 and a lifting chamber 30 from left to right, wherein, the left The support platform 31 is fixedly installed on the top of the support column 2 and the right support column 34, and the right end of the support platform 31 is fixedly connected with the left side of the lifting cavity 30; A filter plate 24 is placed and installed at the bottom of the chamber 5; a liquid outlet pipe 25 communicating with the liquid collection chamber 35 is provided at the bottom of the filter chamber 5, and a liquid discharge valve 36 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com