Injection molding method of liquid crystal television shell and product of injection molding method

A technology for LCD TVs and casings, applied in color TV parts, TV system parts, TVs, etc., can solve problems such as difficulty in recycling, and achieve the effects of reducing environmental pollution, avoiding injection molding defects, and slowing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

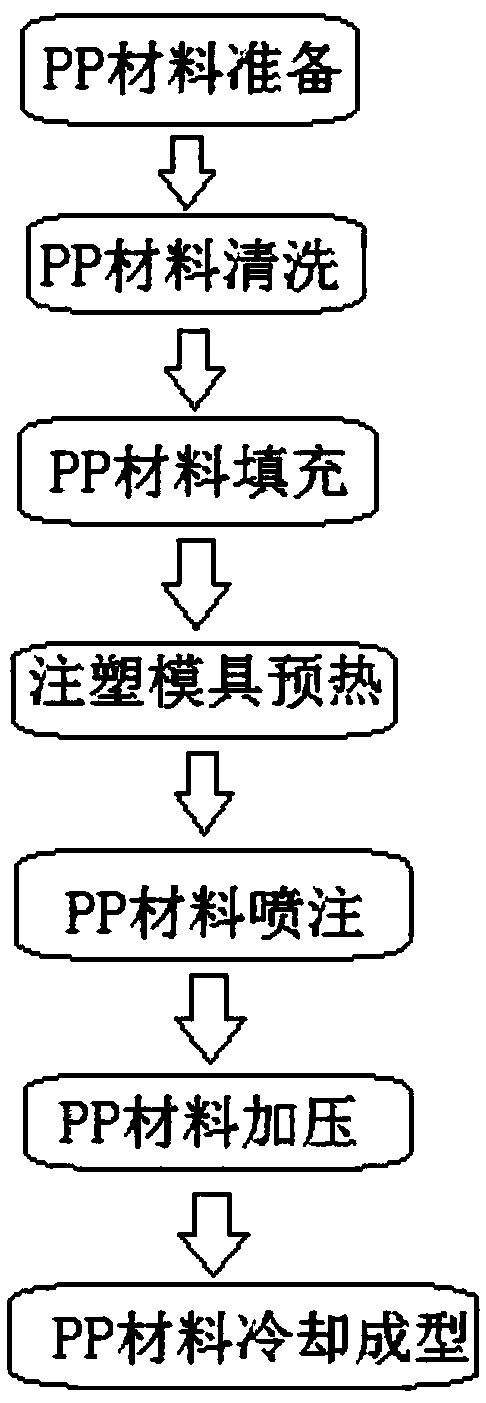

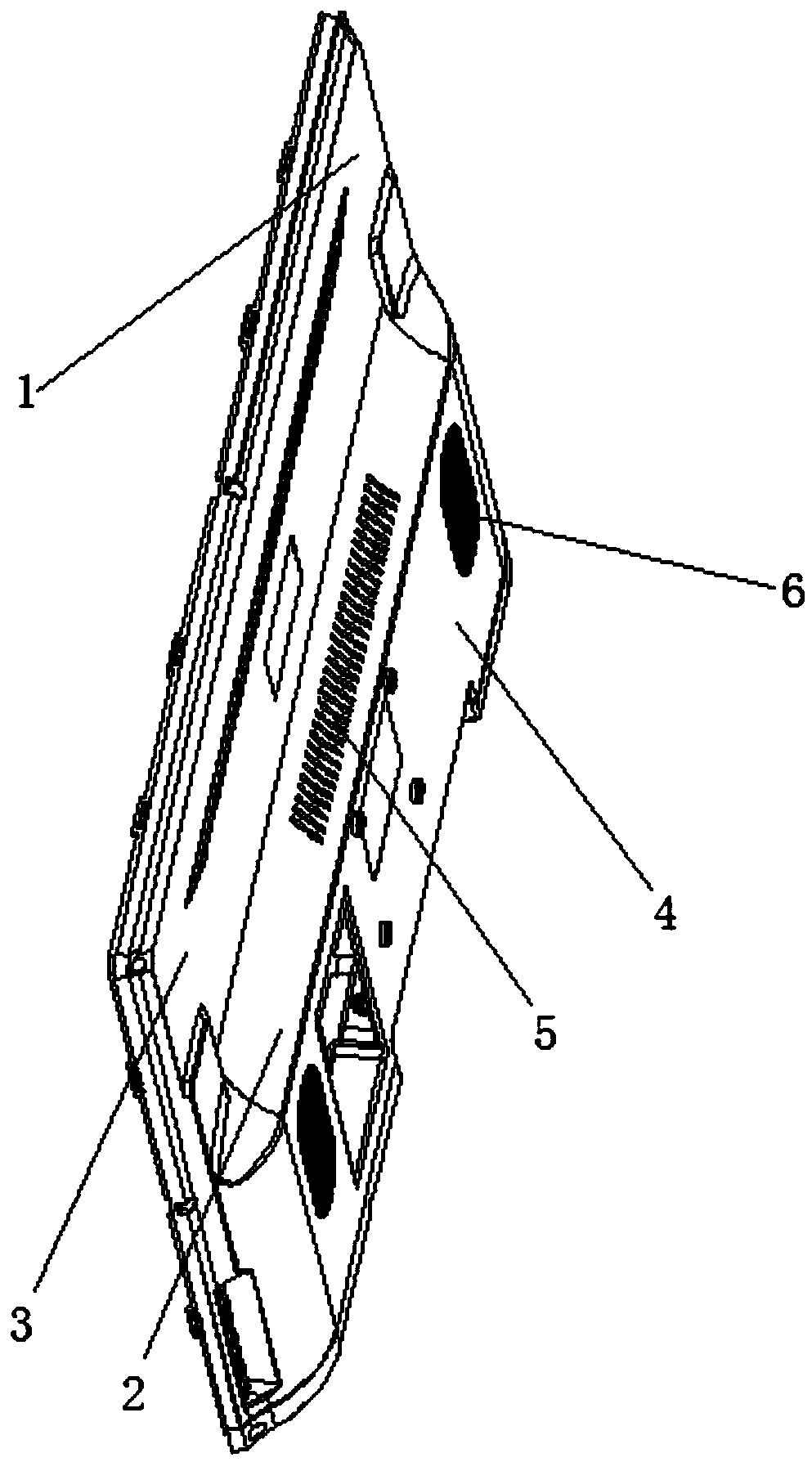

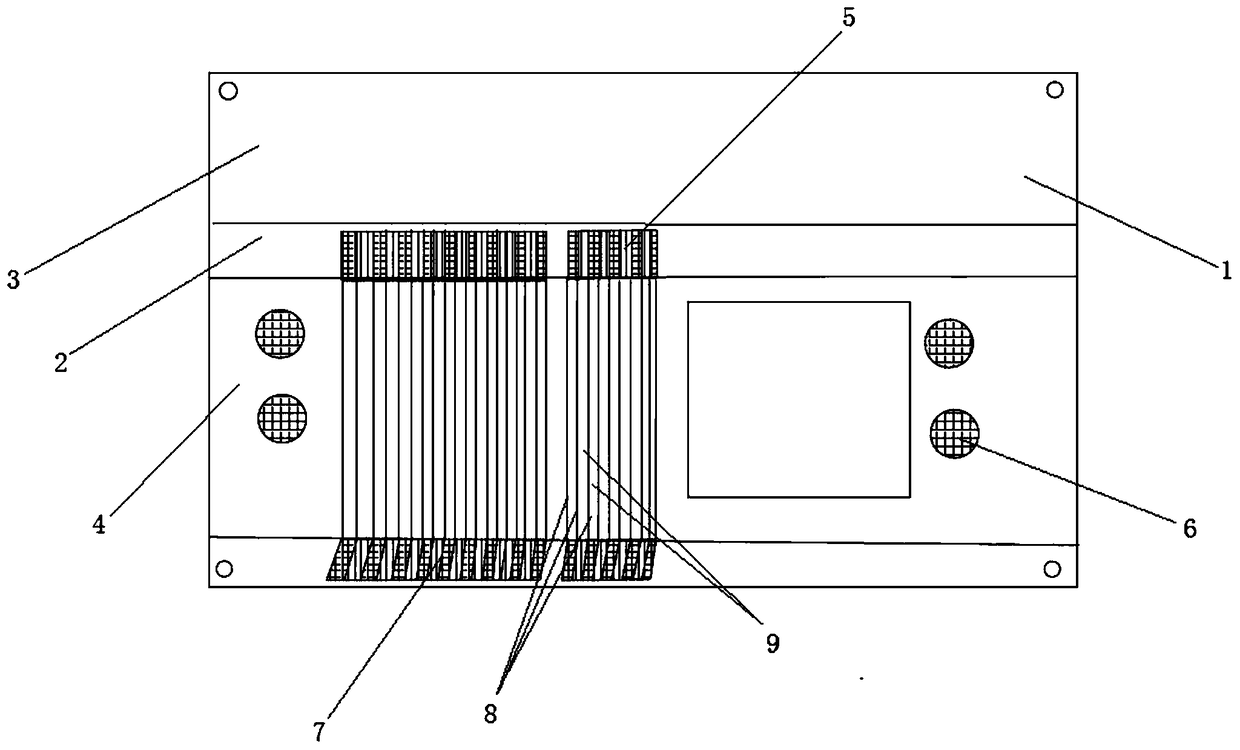

[0042] Example 1: See attached figure 1 , the injection molding method of liquid crystal television housing provided by the invention, described liquid crystal television housing adopts PP regenerated material to make, and it comprises the following steps:

[0043] (1) Prepare PP recycled material, the PP recycled material has a granular structure, after the preparation is completed, clean the PP recycled material particles, put the PP recycled material particles into the non-ionic surfactant solution and soak for 8-15 minutes , then put the PP recycled material particles into clean water for 8-15 minutes, then soak the PP recycled material particles in an alkaline solution with a pH value of 11-12 for 8-15 minutes, and finally put the PP recycled material particles into the Wash in clean water for 8 to 15 minutes to complete the cleaning process of PP recycled material particles;

[0044] (2) Put the cleaned PP recycled material particles into a dryer, and dry them at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com