PCB circuit board delivery device

A technology for PCB circuit boards and transportation devices, which is applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, etc. It can solve the problems of PCB circuit board vibration, PCB circuit board function damage, easy to fall into dust, etc., to speed up speed, slow damage, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

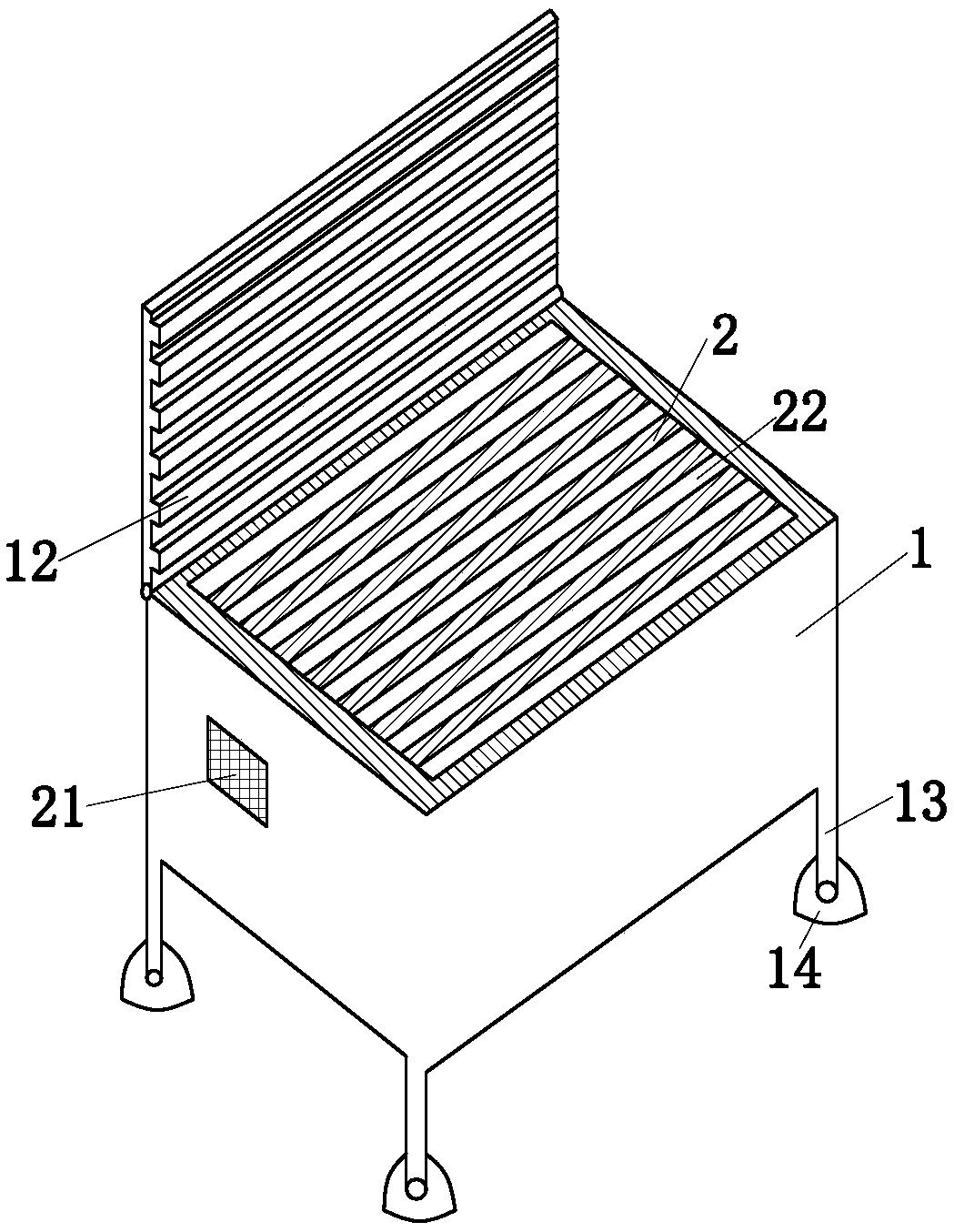

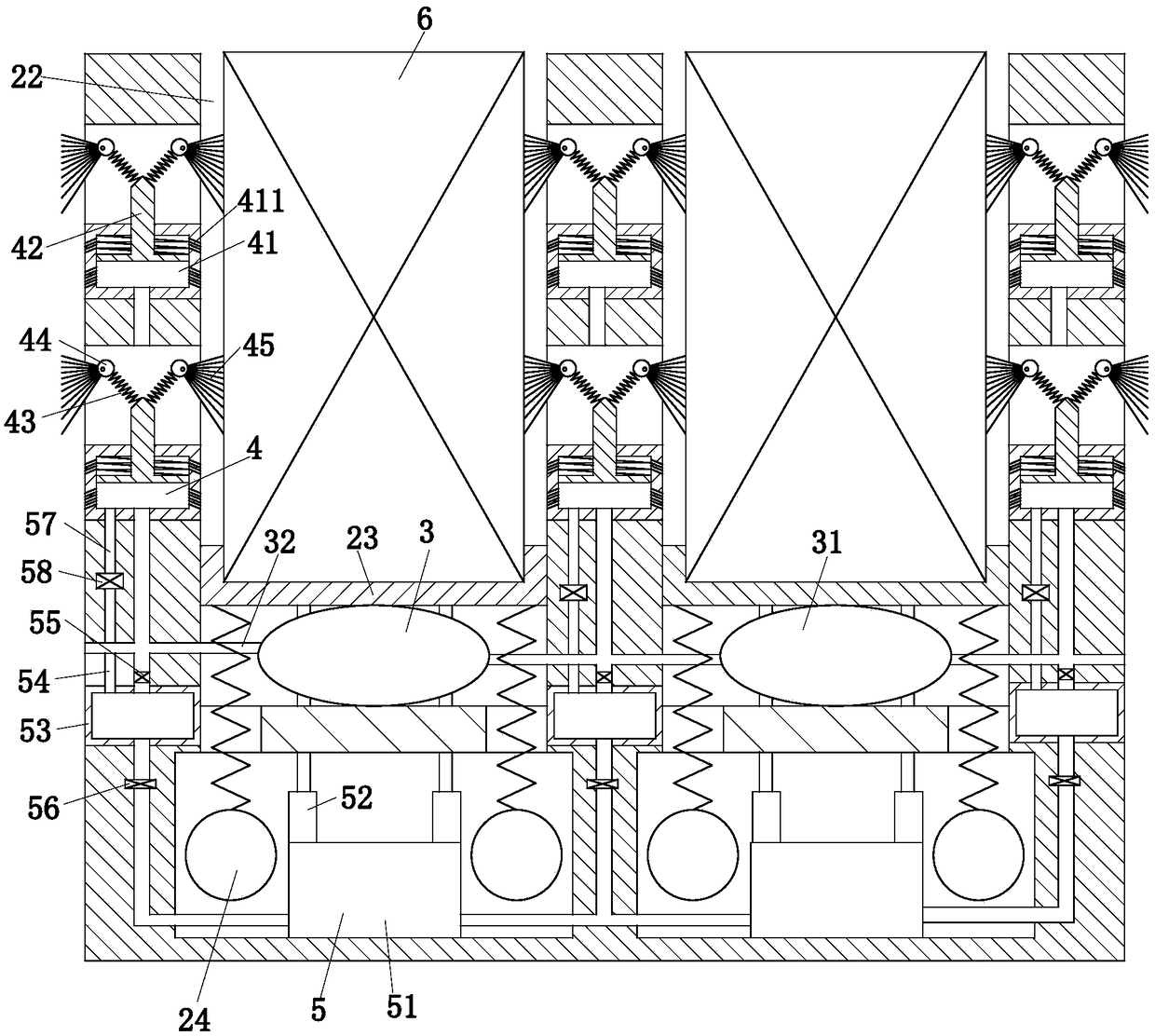

[0023] use Figure 1 to Figure 2 A PCB circuit board transportation device of the present invention is described as follows.

[0024] Such as figure 1 As shown, a PCB circuit board transportation device includes a box body 1, a box cover 12, a box foot 13 and a PCB circuit board placement unit. Adaptation, the box cover 12 is provided with strip ribs, and the strip ribs are used to avoid the direct rigid collision between the PCB circuit board 6 and the box cover 12; the material of the strip ribs is organic silicon material, and the organic silicon material has flexibility; The box feet 13 are located at the four corners of the box body 1, and the box feet 13 are equipped with a Lelo triangular wheel 14 for the walking of the box body 1. The Lailo triangle wheel 14 can improve the up and down vibration amplitude of the PCB circuit board transport device, which is beneficial to the inflation module. 3 fast inflation; the PCB circuit board placement unit is fixed in the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com