Unmanned intelligent warehouse system based on robot

A technology of intelligent warehousing and robots, applied in conveyors, storage devices, transportation and packaging, etc., can solve problems such as reducing work efficiency, difficulty in responding quickly, fire safety hazards, etc., to improve processing and response speed, improve efficiency and Safety and the effect of avoiding fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

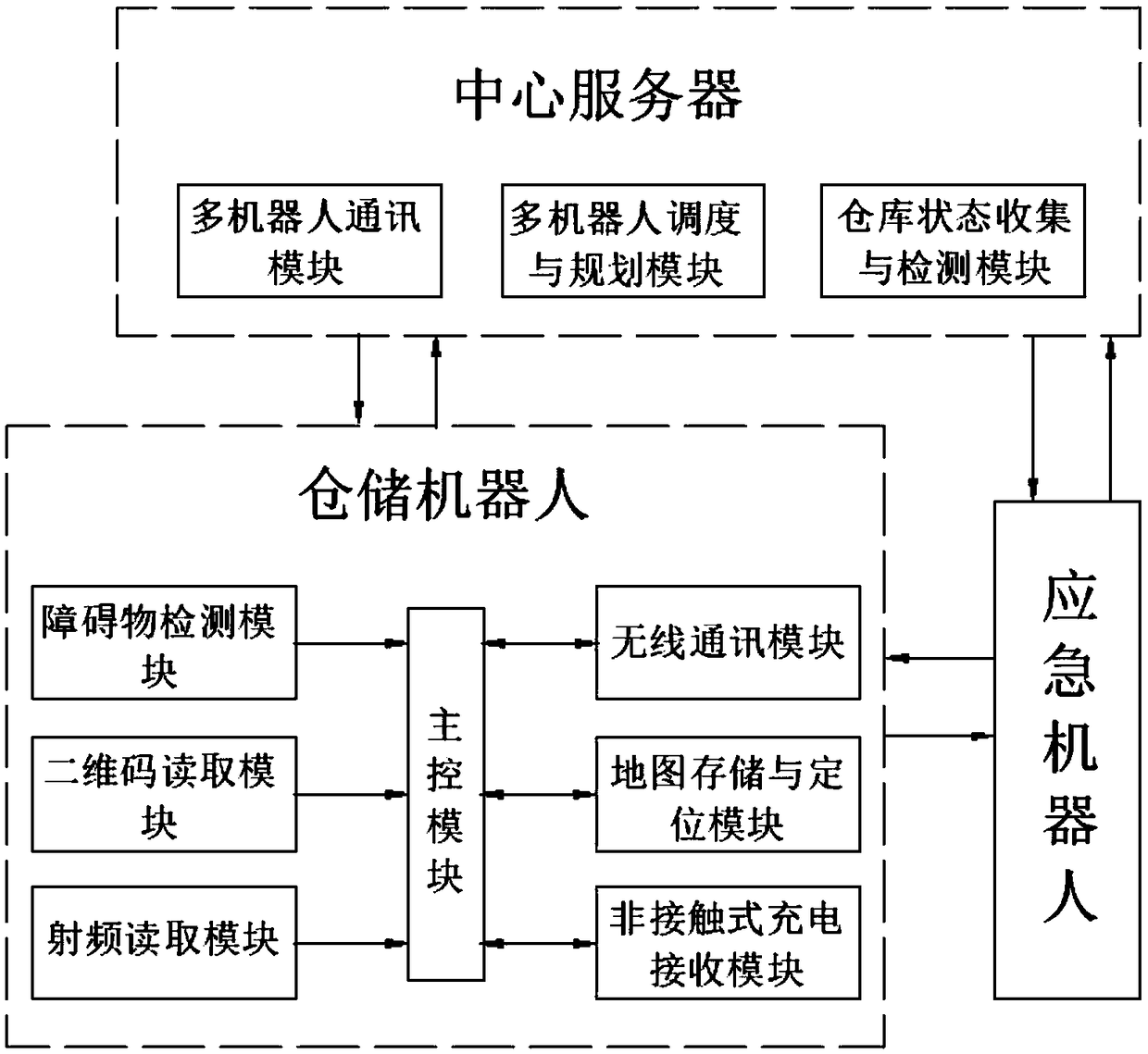

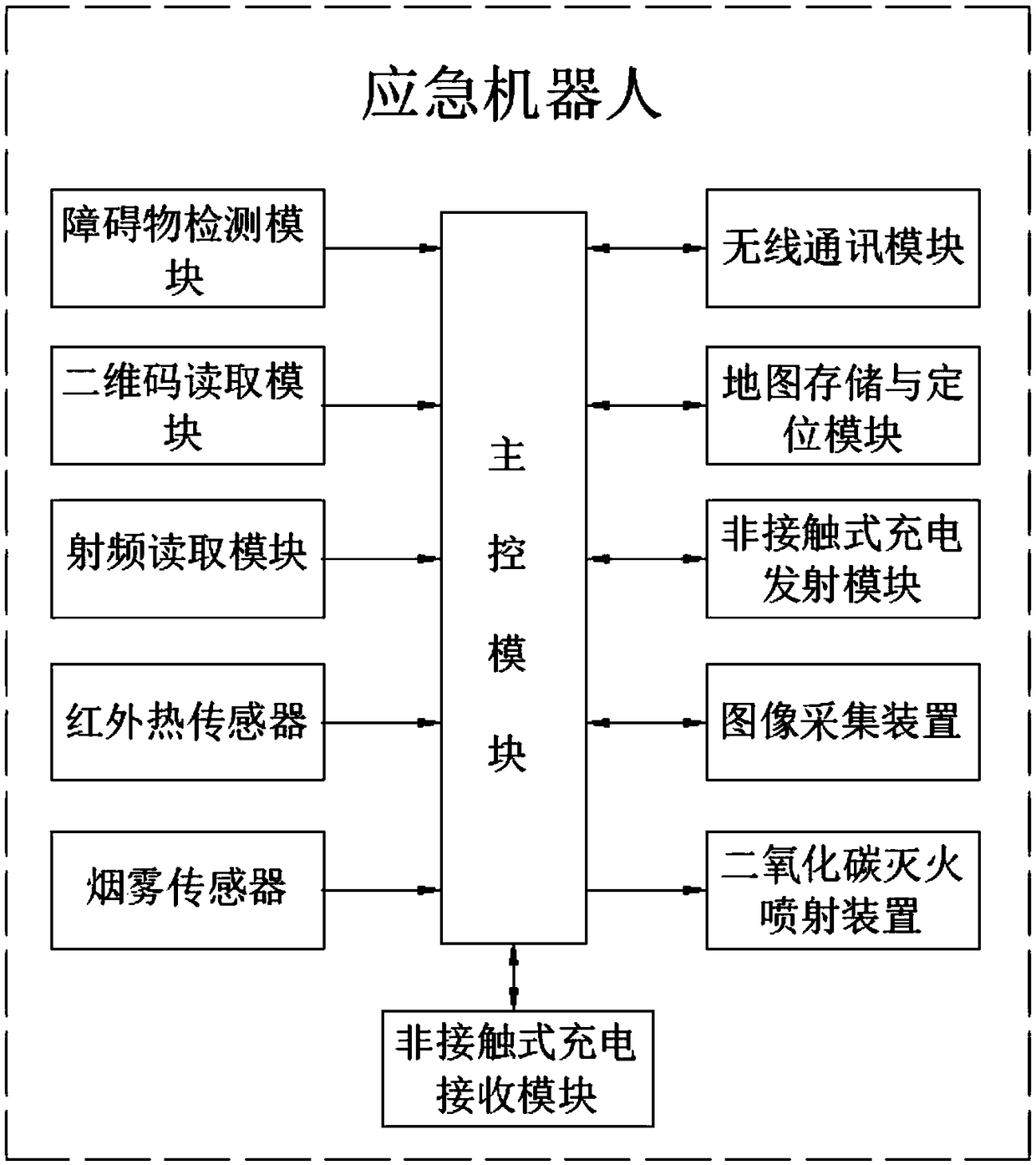

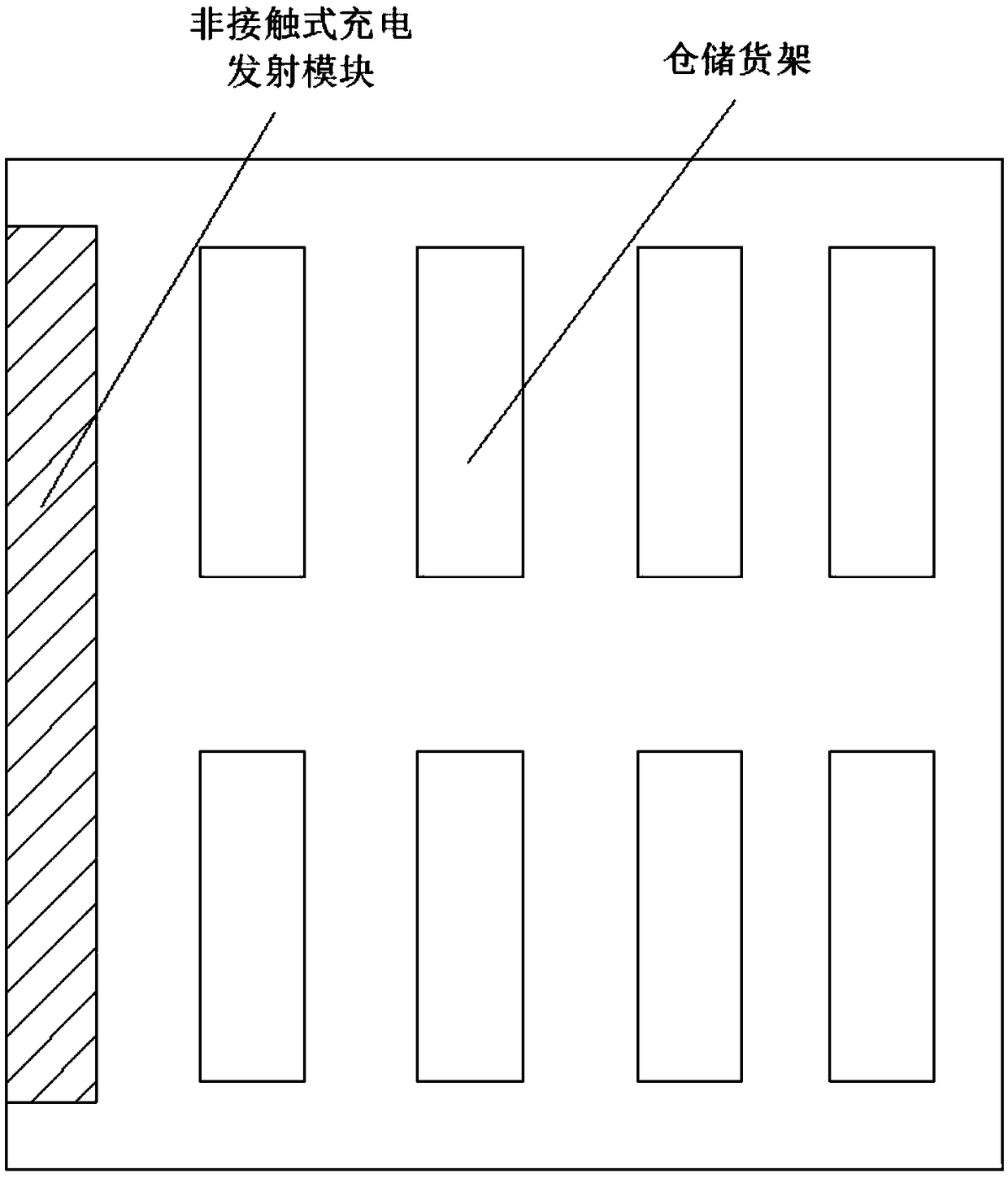

[0037] see Figure 1-2 , an unmanned intelligent warehousing system based on robots, including a central server, a warehousing robot, and an emergency robot. Any two of the central server, warehousing robot, and emergency robot are connected with two-way signals. The central server includes a multi-robot communication module, a multi-robot scheduling With the planning module and warehouse state collection and detection module, the warehouse robot includes a main control module, an obstacle detection module, a two-dimensional code reading module, a radio frequency reading module, a wireless communication module, a map storage and positioning module and a non-contact charging receiving module. module, obstacle detection module, two-dimensional code reading module and radio frequency reading module are all connected to the main control module by one-way signal, and the wireless communication module, map storage and positioning module and non-contact charging receiving module are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com