Industrial storage-resistant, anti-caking fine ammonium perchlorate and preparation method thereof

An ammonium perchlorate and anti-caking technology, which is applied in the direction of ammonium perchlorate composition, offensive equipment, non-explosive/non-thermal agent components, etc., can solve the problem of small crushing amount, short storage period, and impact on propellant performance Larger problems, to achieve the convenience of industrial production, reduce production costs, and improve the effect of storage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The industrialized storage-resistant and anti-caking fine ammonium perchlorate preparation method of the present invention comprises: anti-caking agent is mixed in ammonium perchlorate coarse material, and the addition amount of described anti-caking agent is the mass of ammonium perchlorate coarse material 0.5% to 2% of 0.5% to 2%; crushed by a jet mill to obtain storable and anti-caking fine ammonium perchlorate; the anti-caking agent is a mixture of nano-oxides, aziridine compounds and ester plasticizers , the proportion of each component is: the mass of nano-oxide is 100 parts, the mass of aziridine compound is 40-80 parts, and the mass of ester plasticizer is 40-80 parts. The particle size of the ammonium perchlorate coarse material is 100-140 mesh.

[0023] During the jet milling process, by controlling the crushing pressure at 0.4MPa-0.7MPa and the feed pressure at 0.1MPa-0.4MPa, it can achieve storage resistance and anti-coagulation of different particle sizes (...

Embodiment 1

[0031] In this embodiment, the anti-caking agent is a mixture of nano-alumina, tris(-2methylaziridine-1) phosphorus oxide and butyl phthalate, and the specific ratio is that the quality of nano-alumina is 100 The mass of tris(-2methylaziridine-1)phosphorus oxide is 80 parts, and the mass of butyl phthalate is 40 parts.

Embodiment 2

[0033] In this example, 1.5% by mass of the anti-caking agent prepared in Example 1 was added to the ammonium perchlorate coarse material, mixed evenly, added to the jet mill, and crushed by controlling the crushing pressure and feeding pressure to obtain fine ammonium perchlorate.

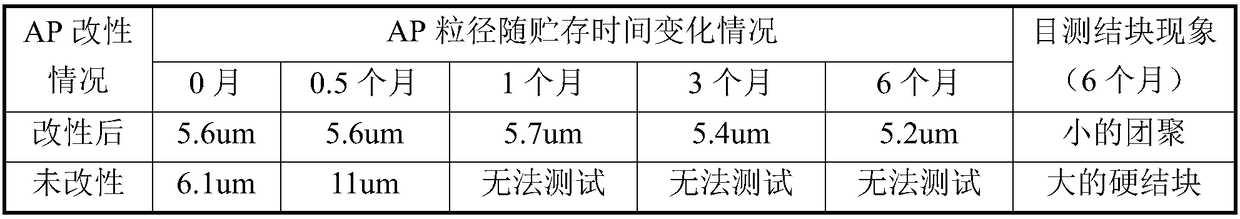

[0034] Table 1 compares the storage effects of the industrialized fine ammonium perchlorate of the prior art and the storability and anti-caking fine ammonium perchlorate prepared in this example.

[0035] Table 1 Comparison before and after modification of fine ammonium perchlorate

[0036]

[0037] Note: The modified fine ammonium perchlorate is packaged in a double-layer polyethylene plastic bag with a built-in silicone belt.

[0038] It can be seen from Table 1 that the particle size of the industrialized fine ammonium perchlorate of the prior art is nearly doubled after being stored for half a month, and has been agglomerated after being stored for 1 month, so particle size testing and appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com