Online switching process for blast furnace blowers

A technology of blower and main blower, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of reducing blast furnace molten iron output, taking a long time, affecting blast furnace forward running, etc., to reduce blast furnace operation cost, stabilize blast furnace forward running, The effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

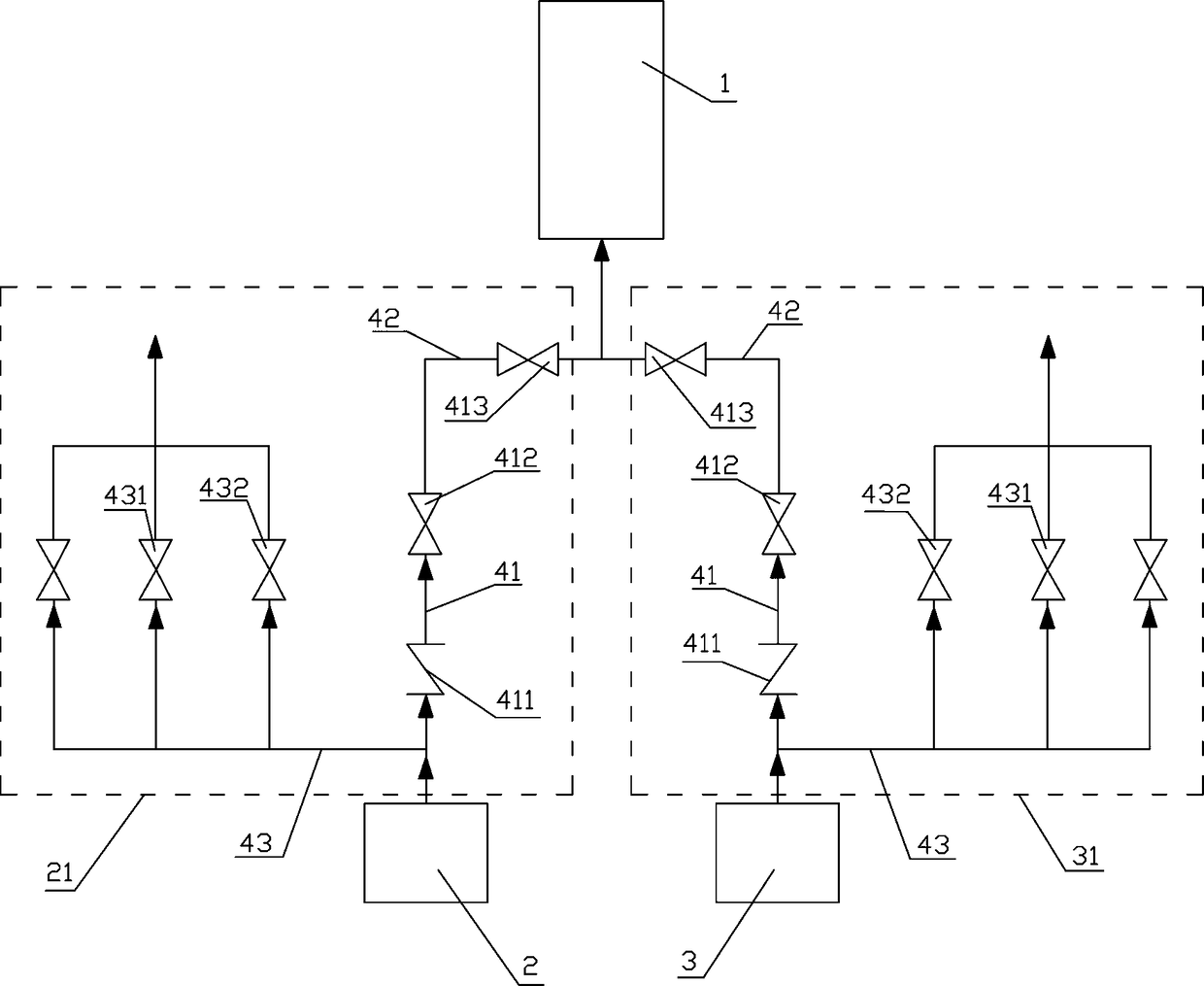

[0014] Such as figure 1 As shown, a blast furnace blower online switching process, the process steps are as follows:

[0015] (1) When molten iron is tapped from the blast furnace 1, start the standby blower 3, open and adjust the valve on the discharge pipeline 43 in the standby air supply pipe network 31 corresponding to the standby blower 3 to adjust the air outlet pressure of the standby blower 3, so that Air outlet pressure of standby blower 3=F+4~6kPa, F=70~75% of air outlet pressure of main air blower 2 before molten iron tapping of blast furnace 1, preferably F=75% of air outlet pressure of main air blower 2 before molten iron tapping of blast furnace 1 , the air outlet pressure of standby air blower 3=F+5kPa, in the present embodiment, the air outlet pressure of standby air blower 3 rises to 305kPa;

[0016] (2) After the blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com