Textile edge moving device

A sizing device and side plate technology, which is applied in the direction of fabric trimming, textile and papermaking, fabric surface trimming, etc., can solve the problems of low quality of cloth edge products, easy rewinding of fabric sides, and high labor intensity, etc., to achieve The effect of improving production efficiency and product quality, flexible use, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

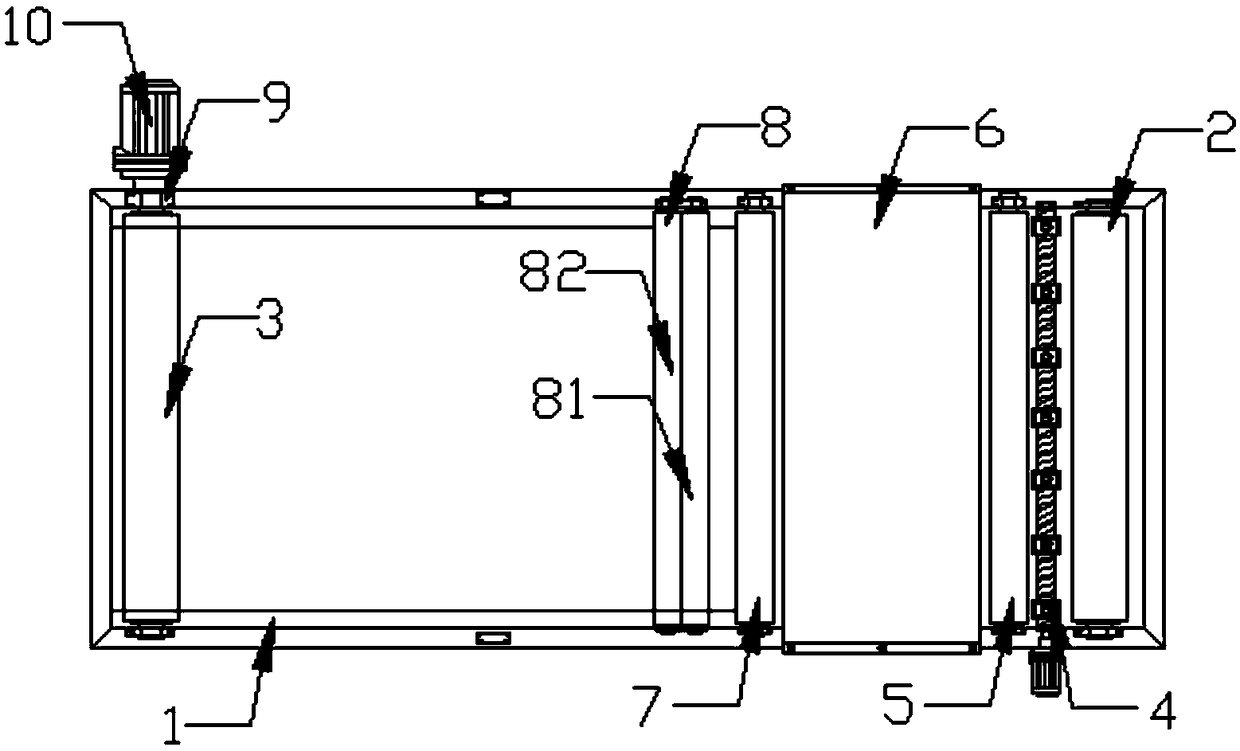

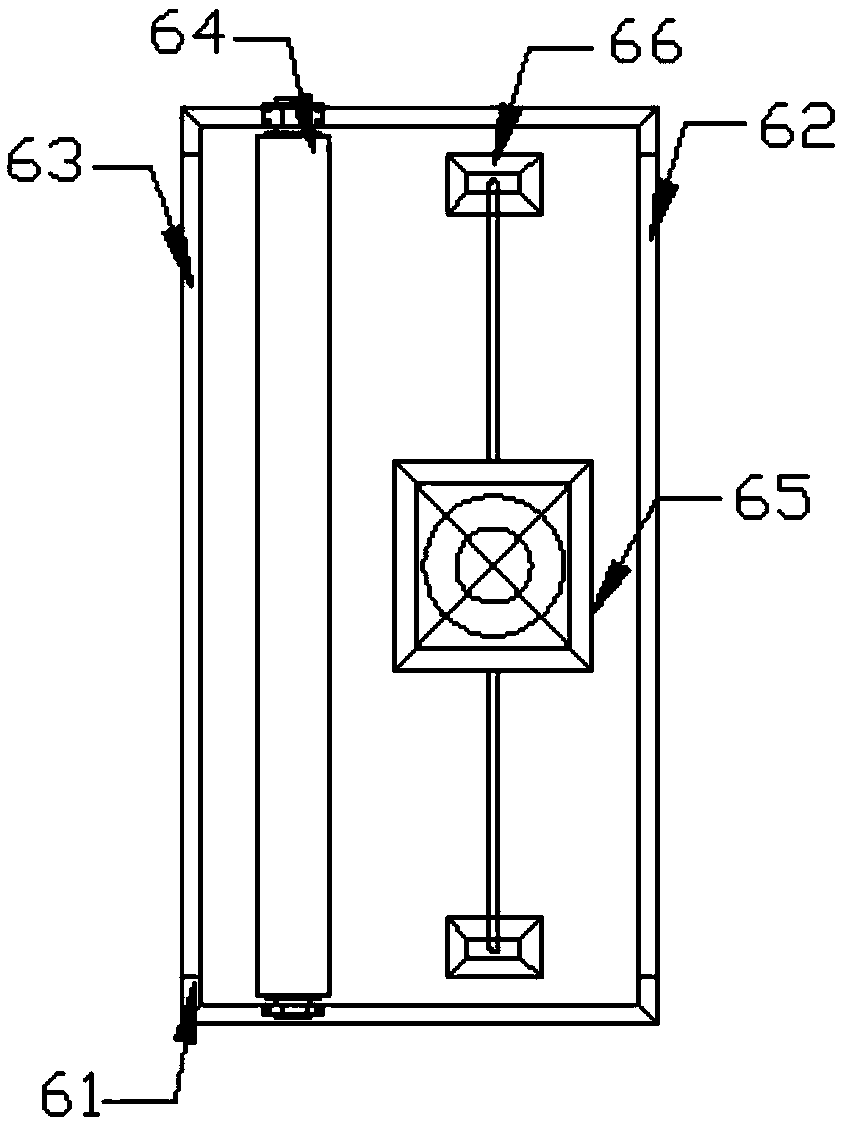

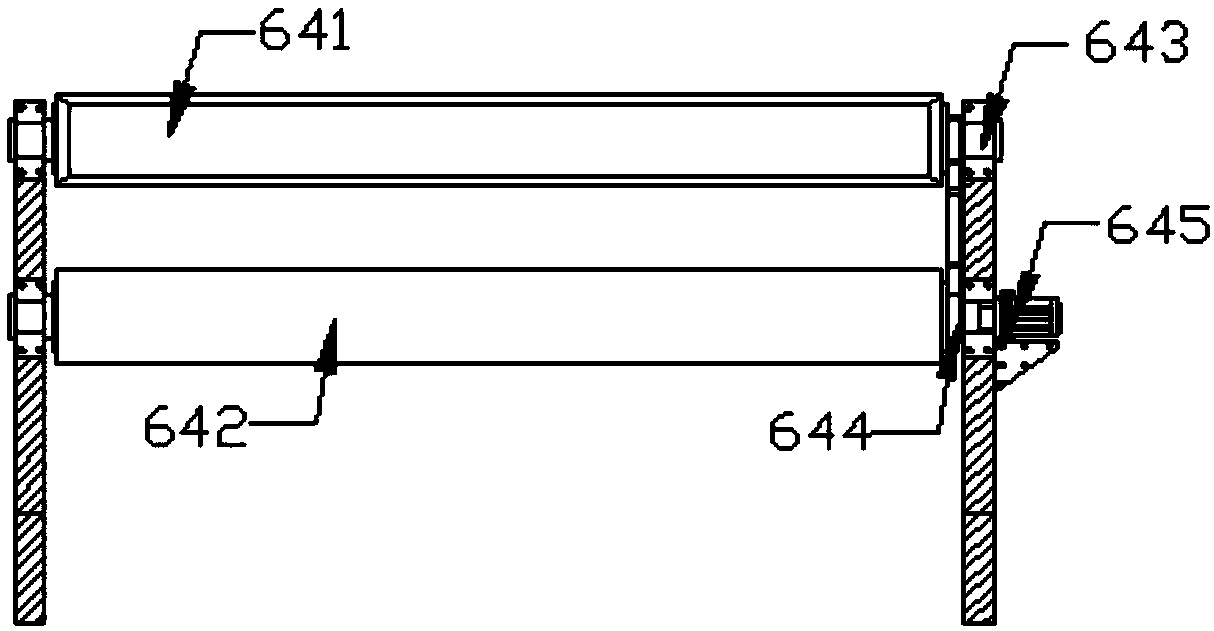

[0021] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a kind of edge setting device for weaving, including edge setting workbench 1, cloth material roller 2, cloth winding roller 3, edge setting mechanism 4, edge setting device 6 and conduction Roller 8, the bottom of described edge-setting workbench 1 is fixedly installed with support frame, the top of described edge-setting workbench 1 is fixedly installed with frame 9 by bolts, and the frame 9 at one end of described edge-setting workbench 1 passes through The bearing seat is rotatably equipped with a cloth material roller 2, and the frame 9 at the other end of the edge-setting workbench 1 is installed with a cloth take-up roller 3 through the bearing seat rotation, and the cloth material roller 2 is close to the side of the cloth take-up roller 3 A side-setting mechanism 4 is installed on the top of the side-setting workbench 1, and a first material guide roller 5 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com