Pipe dredging robot based on wall supporting linkage mechanism and use method thereof

A link mechanism and robot technology, applied in waterway systems, water supply devices, buildings, etc., can solve the problems of size interference and large robot dimensions, and achieve the effects of reasonable structural design, improved automation and intelligence, and convenient air pressure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

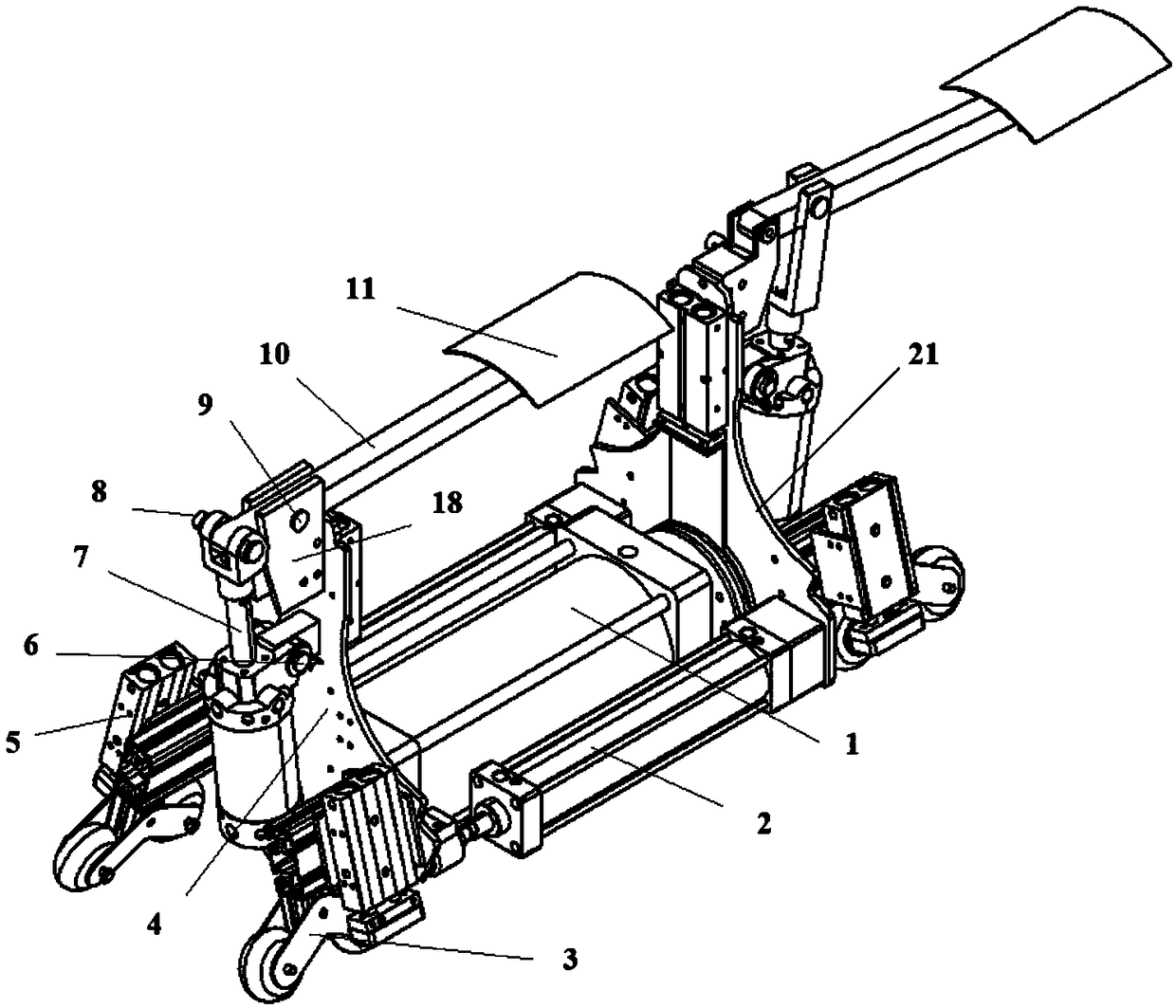

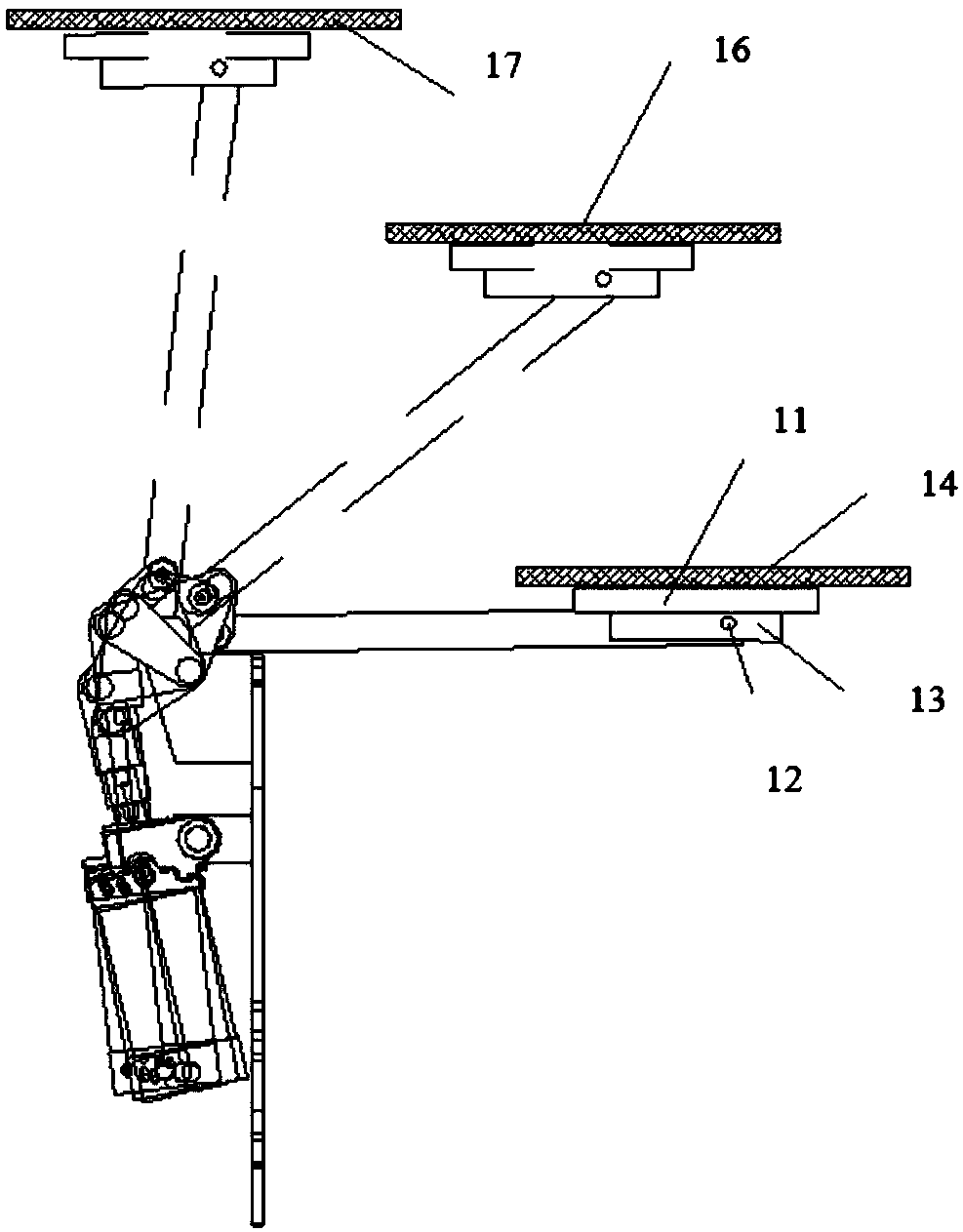

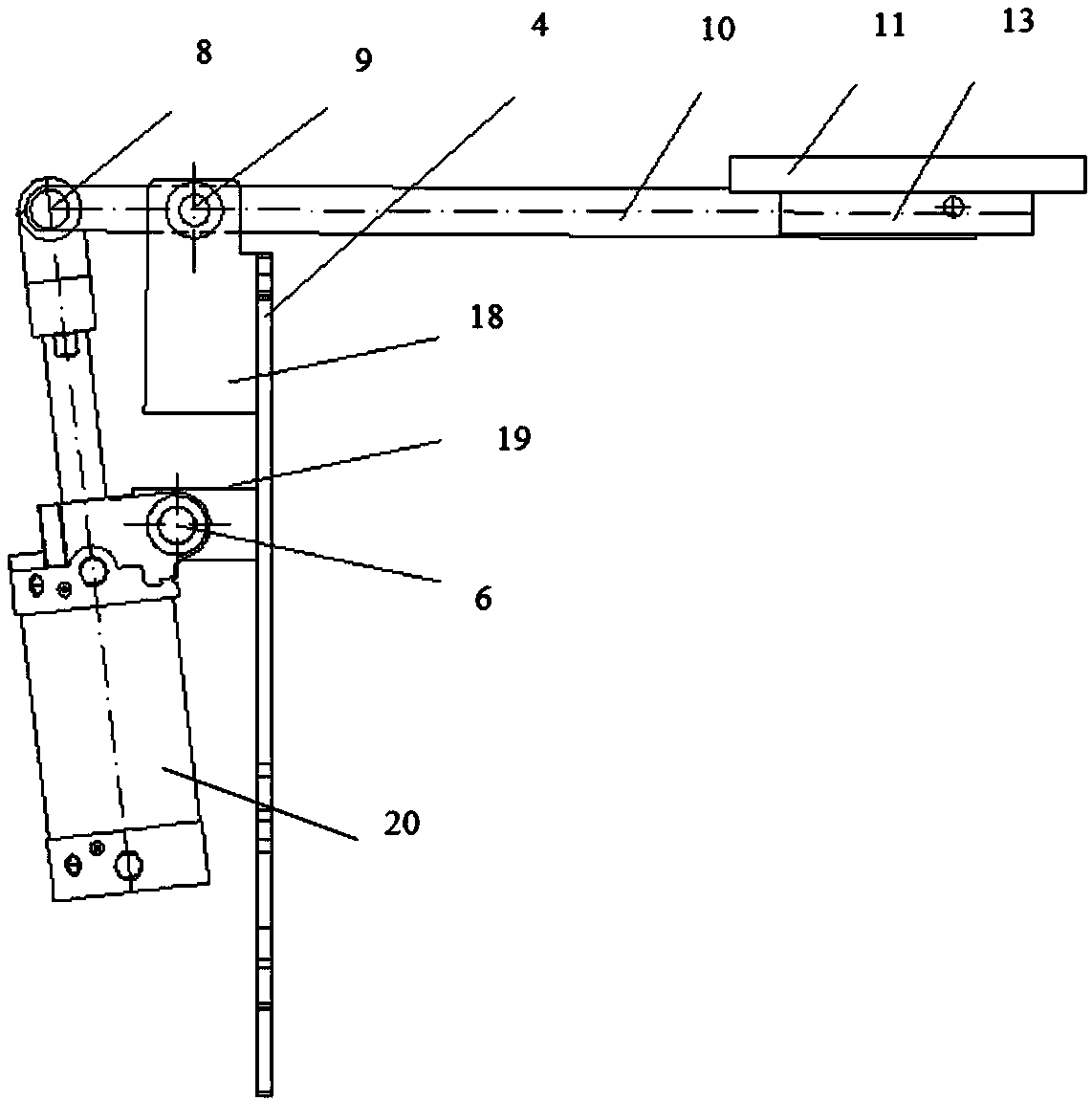

[0025] Attached below Figure 1-3 The pipeline dredging robot based on the support wall linkage mechanism and its use method of the present invention are described in detail.

[0026] A pipeline dredging robot based on a support wall linkage mechanism, the pipeline dredging robot includes a dredging cylinder 1, a telescopic cylinder 2, a front mounting plate assembly, a rear mounting plate assembly, a wall support rod assembly and a walking assembly; wherein, the Both the front mounting plate assembly and the rear mounting plate assembly include a connecting rod hinge seat 18 and a drive cylinder hinge seat 19, and the front mounting plate assembly also includes a front mounting plate 4; the rear mounting plate assembly also includes a rear mounting plate 21; The rod hinge seat is fixedly installed on the top of the installation plate, and the drive cylinder hinge seat is fixedly installed in the middle of the installation plate; Silt; the cylinder body of the telescopic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com