Drilling trolley suitable for existing line operation

A technology of drilling jumbo and existing lines, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and production, etc. It can solve the problems of many restrictive conditions, inconvenient construction, and narrow construction site, so as to reduce idle time and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

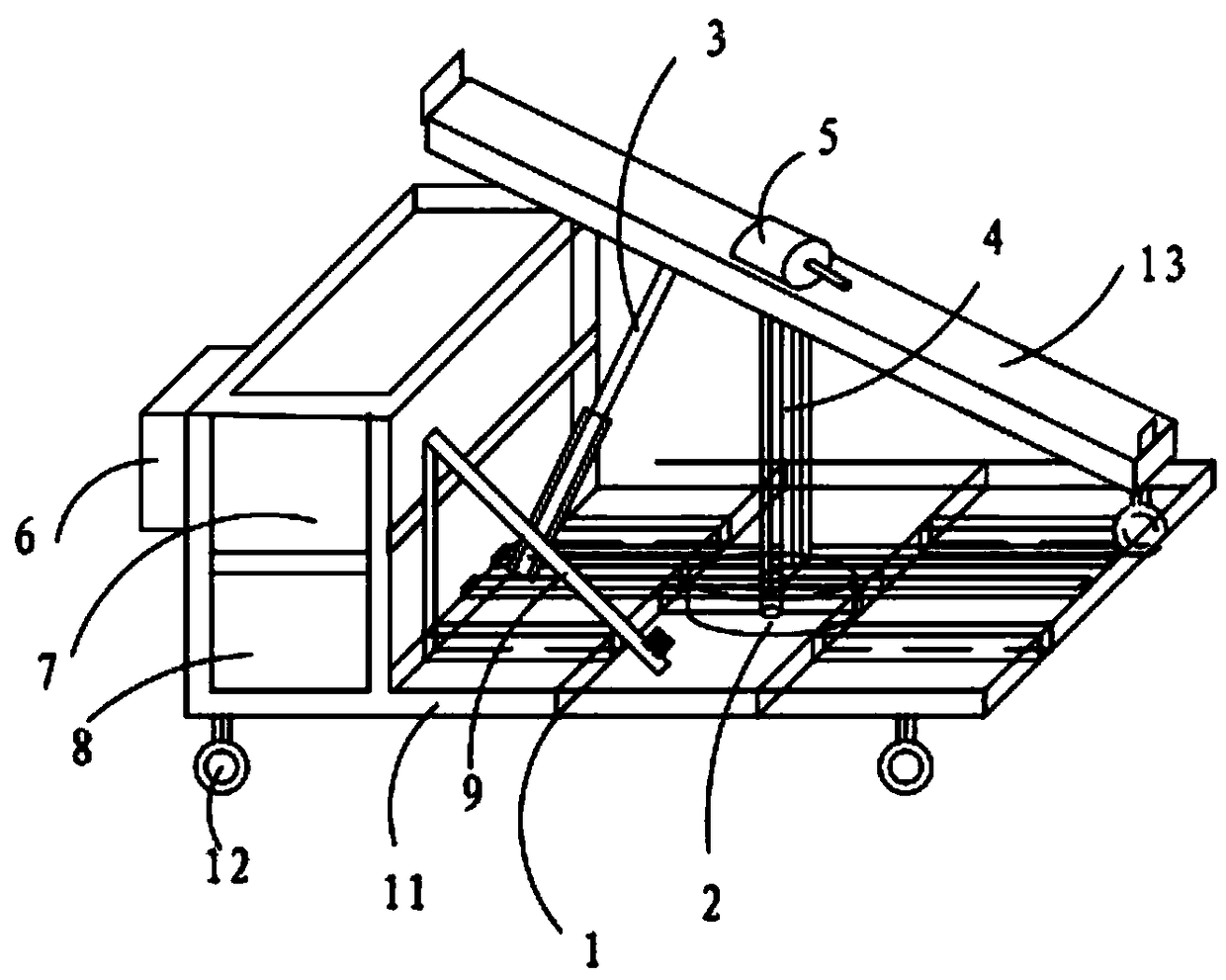

[0024] like figure 1 As shown, the present invention is a kind of drilling jumbo suitable for existing line operations, including a track flat travel system 1, a horizontal hydraulic rotation system 2, a vertical hydraulic rotation system 3, a down-the-hole Drill main body support 4, down-the-hole drilling traction motor 5.

[0025] The track plate type walking system 1 comprises a chassis 6 and a plurality of sets of pulleys 12 arranged under the chassis 6 .

[0026] In the present embodiment, the track plate type walking system 1 includes four sets of rubber pulleys, which are respectively arranged at the four corners below the chassis 6, and the wheelbase is designed to be 1.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com