Portable filling mining tamping simulating device

A simulation device and a portable technology, which can be applied to filling materials, safety devices, mining equipment, etc., can solve the problems of large deviation between laboratory and field results, crude experimental equipment, and insufficient tamping thrust, so as to increase the tamping effect and improve standardization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

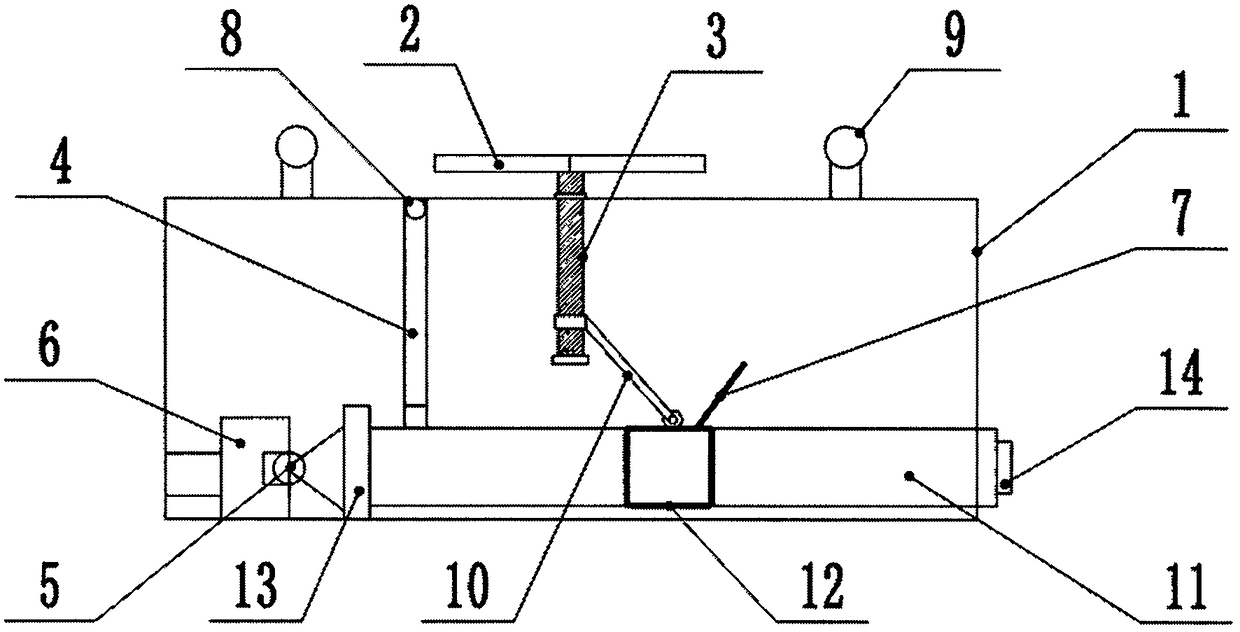

[0012] like figure 1 Shown is a schematic structural diagram of a portable filling, mining and tamping simulation device of the present invention. The device is mainly composed of a box body 1, a rotating handle 2, a rotating threaded rod 3, a separate hydraulic jack, an oil delivery hose 4, and a spherical joint 5. , hinged joint support 6, side limit plate 7; box body 1 is welded by steel plate with a thickness of 1cm, and the top cover is fixedly connected with bolts, which is convenient for dismantling the top cover, which is convenient for the objects inside the box body 1. Maintenance repairs. Convenient disassembly In order to make the box body 1 provide sufficient support without deformation, the rear plate of the box body 1 is welded with a steel plate with a thickness of 2 cm, and the outer surface of the entire box body 1 is sprayed with a layer of blue paint. A round hole is left on the upper part of the box body 1, and the quick connector 8 on the oil delivery ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com