Method and device for testing length of water column in drilling hole for measuring gas pressure

A gas pressure and testing device technology, applied in gas discharge, mining devices, safety devices, etc., can solve the problems of uncontrollable gas and water release, complicated operation, error deviation, etc., to improve the accuracy of hydraulic testing, ingenious process, eliminate effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

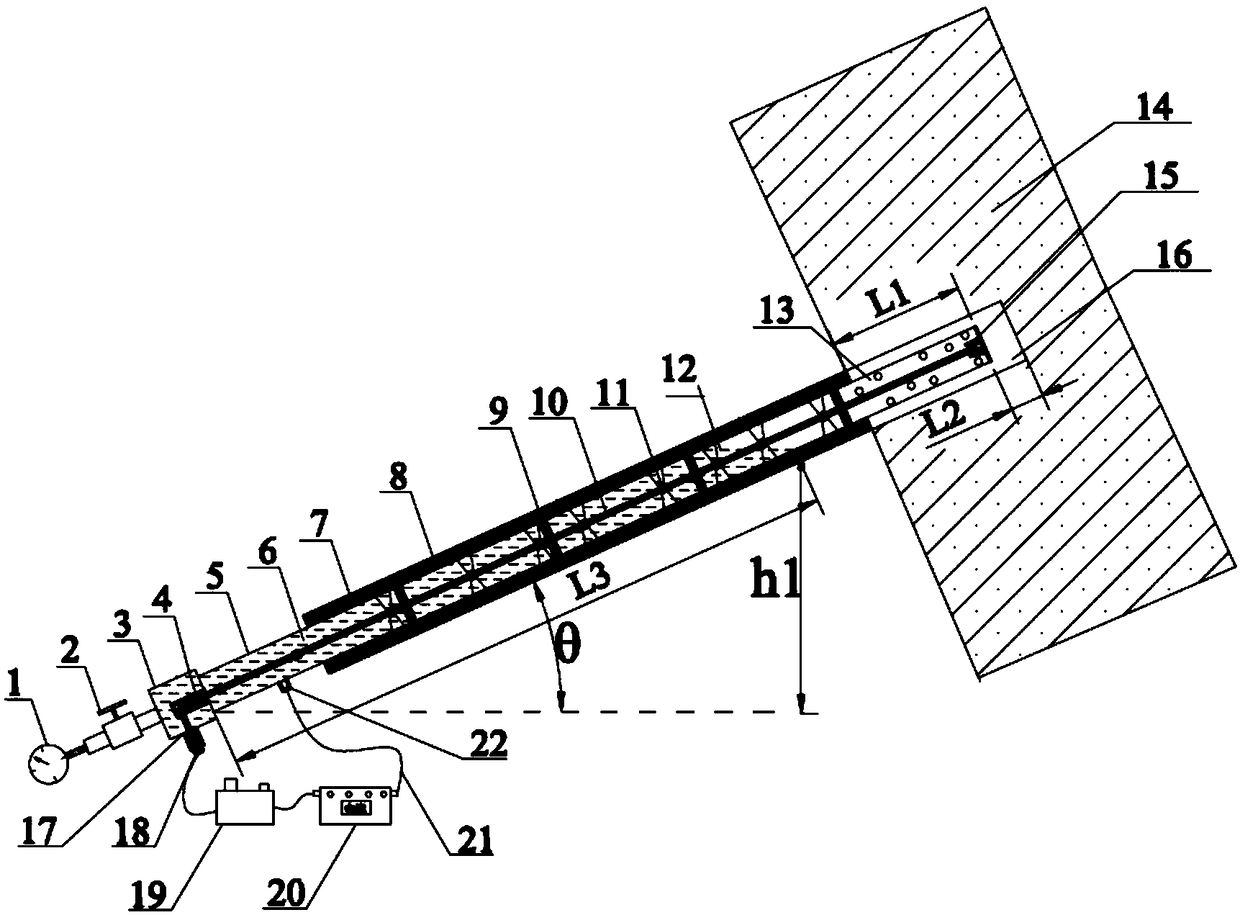

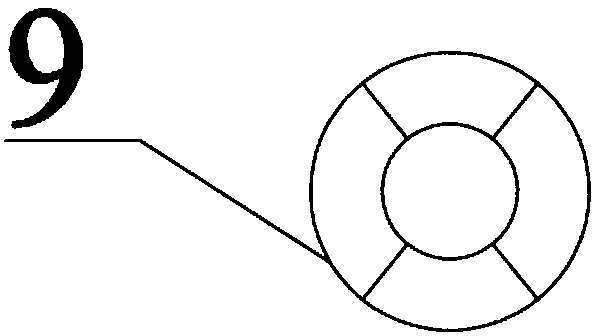

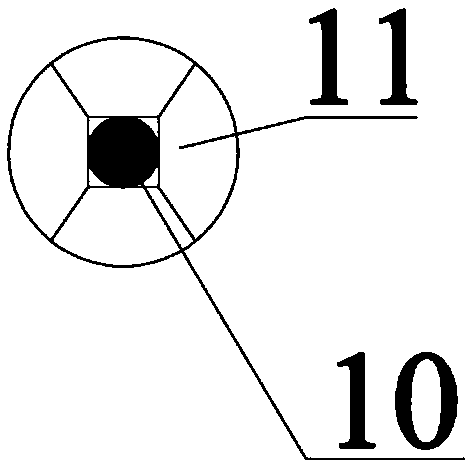

[0044] Such as Figure 1-Figure 3 As shown, this embodiment proposes a gas pressure measuring device for measuring the length of water column in a borehole, including a pressure measuring steel pipe 5, a stainless steel wire 10, an insulating sleeve 15, a DC power supply with readable current and variable output voltage, a rheostat box and a precision pressure gauge. Table 1, wherein the front section of the steel pipe has a number of distributed holes, so that the front section of the steel pipe forms a pressure measuring flower tube 13, the center of the pressure measuring steel pipe 5 has a built-in stainless steel wire 10, and the pressure measuring steel pipe 5 and the stainless steel wire 10 are arranged at intervals, and the pressure measurement The end face between the front end of the steel pipe 5 and the front end of the stainless steel wire 10 is sealed by an insulating sleeve 15; The total pressure of the gas and liquid in the piezometer borehole; the first electro...

Embodiment 2

[0054] The present embodiment proposes the test method for measuring the length of the water column in the borehole by gas pressure, and uses the test device for measuring the length of the water column in the borehole by the gas pressure proposed in Example 1, including the following steps:

[0055] Step 1. Construct the oblique pressure measurement borehole 8 at the predetermined position underground and enter the target coal seam 14, and use the compressed air system or high-pressure water to flush the residual debris in the hole, and wait for the hole to be sealed for pressure measurement;

[0056] Step 2. Insert the pressure measuring flower pipe 13 into the pressure measuring borehole 8, the length of the front section of the pressure measuring flower pipe 13 from the bottom of the pressure measuring borehole 8 is less than 1m, and seal the pressure measuring steel pipe 5 in the coal rock body, Form the sealing section 7;

[0057] Step 3. Open the three-way valve 2 to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com