A dual-purpose combined filter

A combined filter technology, applied in the direction of machines/engines, charging systems, vehicle components, etc., can solve the problems of filter displacement, deformation, waste, and insufficient positioning, so as to prevent displacement and deformation and reduce the cost of use , The effect of strong product versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

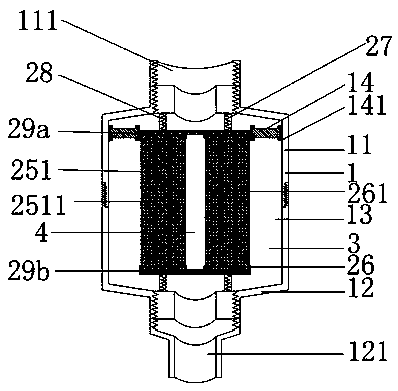

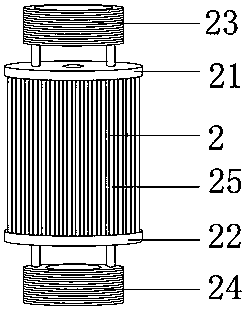

[0023] The invention provides a dual-purpose combined filter, which is applied in the technical field of auto parts and used for filtering out impurities in an auto air-conditioning system. see figure 1 and image 3 , as shown in the figure, the dual-purpose combined air filter of the present invention includes a housing 1 and a filter element 2, wherein the housing 1 includes an upper shell 11 and a lower shell 12, and the upper shell 11 and the lower shell 12 are connected to form A cavity 13, the filter element 2 is arranged in the cavity 13, the filter element 2 has a hollow cylindrical structure, the outer wall of the filter element 2 and the inner wall of the housing 1 form the air inlet channel 3 of the dual-purpose combined filter, and the center of the filter element 2 forms two With the air exhaust duct 4 of the combined filter, the lower shell 12 is provided with an air inlet 121 corresponding to the air intake duct 3, and the upper shell 11 is provided with an air...

Embodiment 2

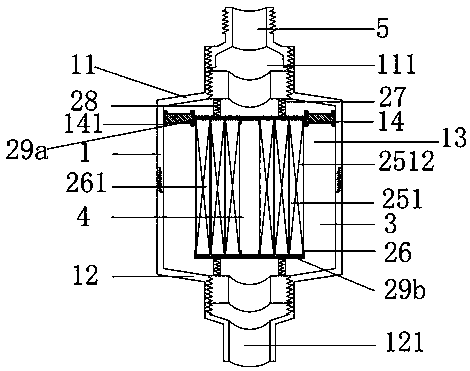

[0031] The invention provides a dual-purpose combined filter, which is applied in the technical field of auto parts, and is used for filtering out impurities in the air in an automobile engine, so as to reduce the wear of the impurity particles on various parts in the cylinder. see figure 2 and image 3 , as shown in the figure, the difference between this embodiment and embodiment 1 is:

[0032] In this embodiment, the three filter layers 251 are filter paper layers 2512 with successively decreasing pore sizes, and multi-layer filter paper layers 2512 with different pore sizes are used for filtering to prevent insufficient removal of impurities and serious wear of the piston caused by the use of filter paper layers 2512 with large pore sizes. The problem is that when the small-diameter filter paper layer 2512 is used, the solid particles block the filter holes, the air volume and wind pressure through the filter paper layer 2512 are small, and it is impossible to provide su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com