Air bag type wind power blade structure

A wind power blade and airbag technology, applied in the field of renewable new energy wind power blades, can solve the problems of cracking and damage of the bonding surface of the half shell and the half shell, fatal blades and the whole machine, difficult quality control, etc., and achieve material cost. And the effect of low installation and maintenance cost, reducing fatigue damage and reducing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

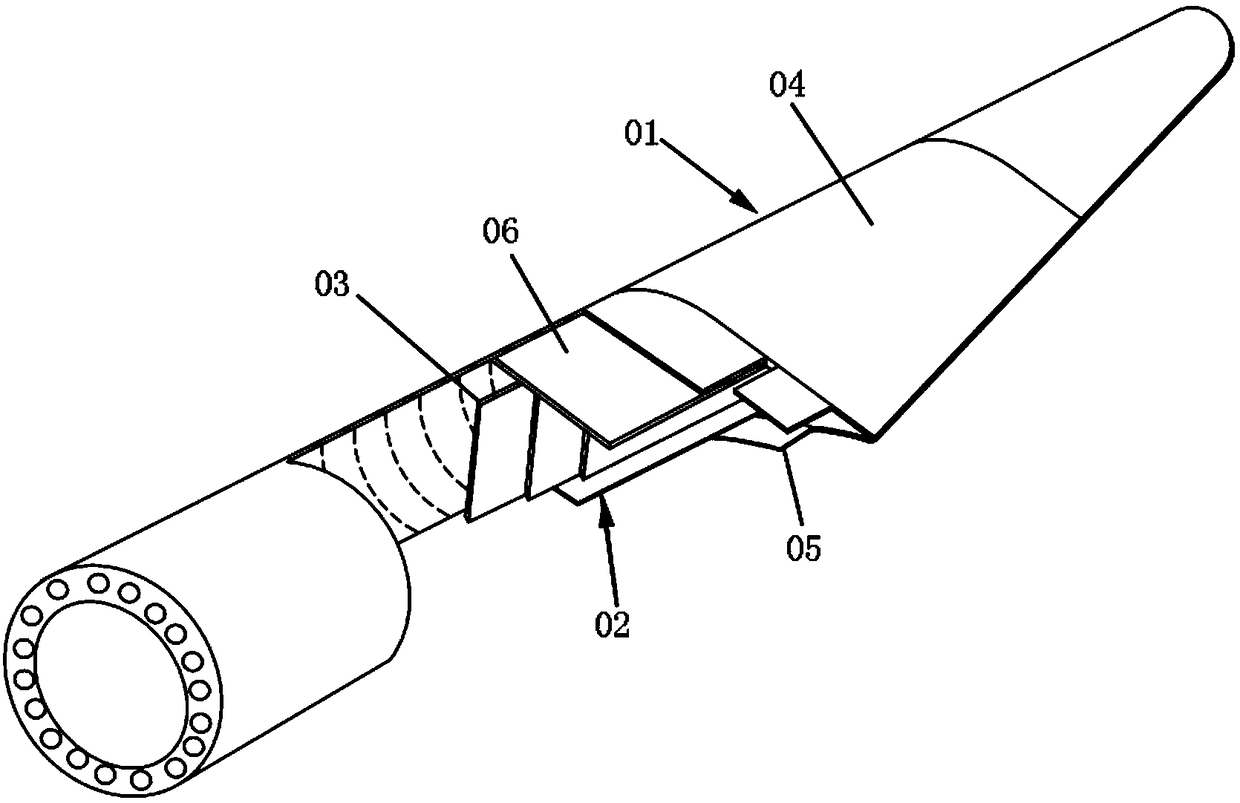

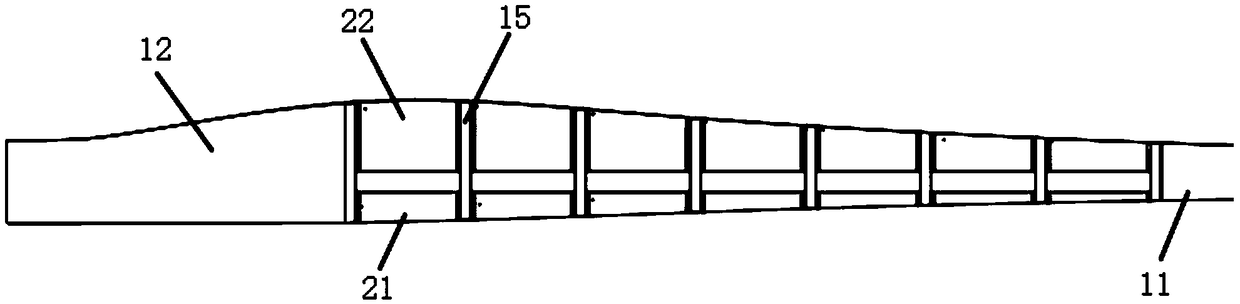

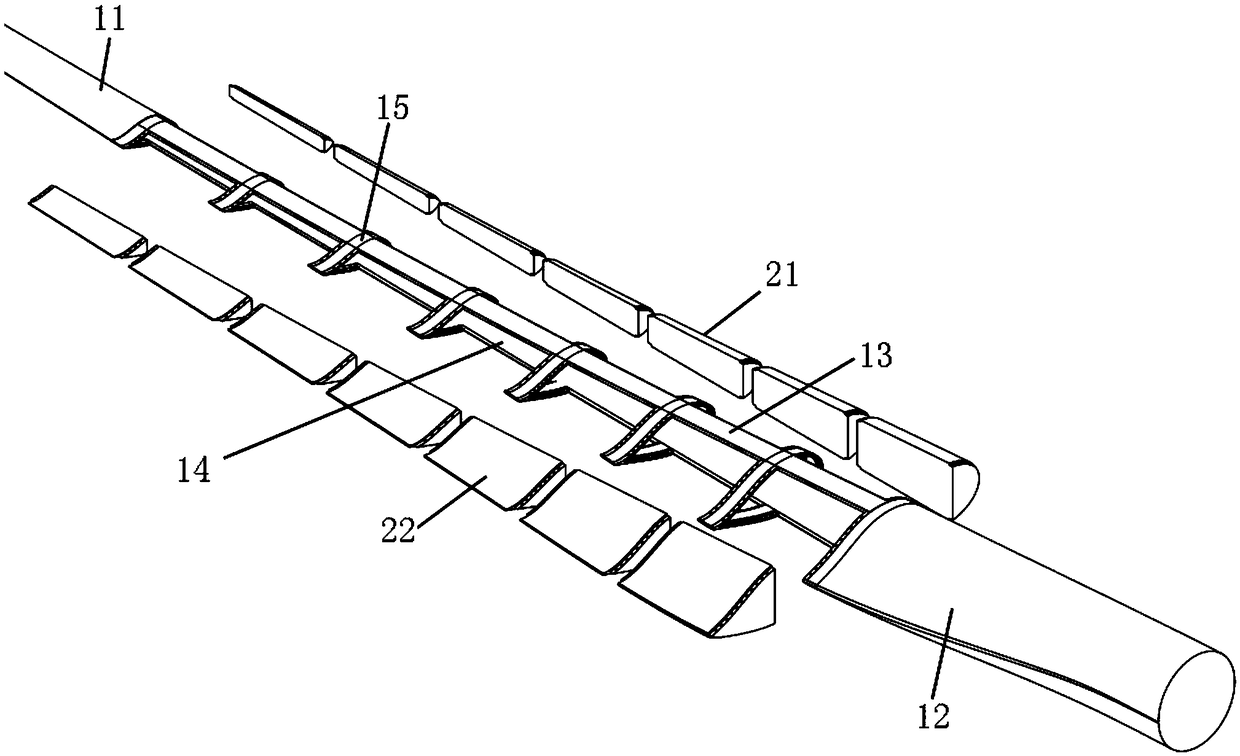

[0022] see Figure 2 to Figure 7 As shown, the airbag-type wind turbine blade structure provided in this embodiment includes a structural skeleton and multiple sets of blade body airbags. The main girder 14 on the windward side, the main girder 16 on the leeward side and the airbag installation flange 15 are composed. Formed by the bonding process, it plays the role of anti-shearing during the operation of the entire wind power blade. The main beam 14 on the windward side and the main beam 16 on the leeward side are the main load-bearing structures of the entire structural skeleton, and are respectively connected to the tip of the blade through a vacuum infusion process. The windward side and the leeward side of the section shell 11 and the blade root section shell 12 are integrally formed, and a section of main beam is reserved between the blade tip section shell 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com