PCM energy storing structure capable of increasing crystallization speed of phase-change energy storing material

A technology of phase change energy storage and crystallization speed, applied in heat storage equipment, heat exchanger types, lighting and heating equipment, etc., can solve the problems of poor heat storage performance and slow crystal nucleus nucleation speed, and increase the area , increasing the effect of probability and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

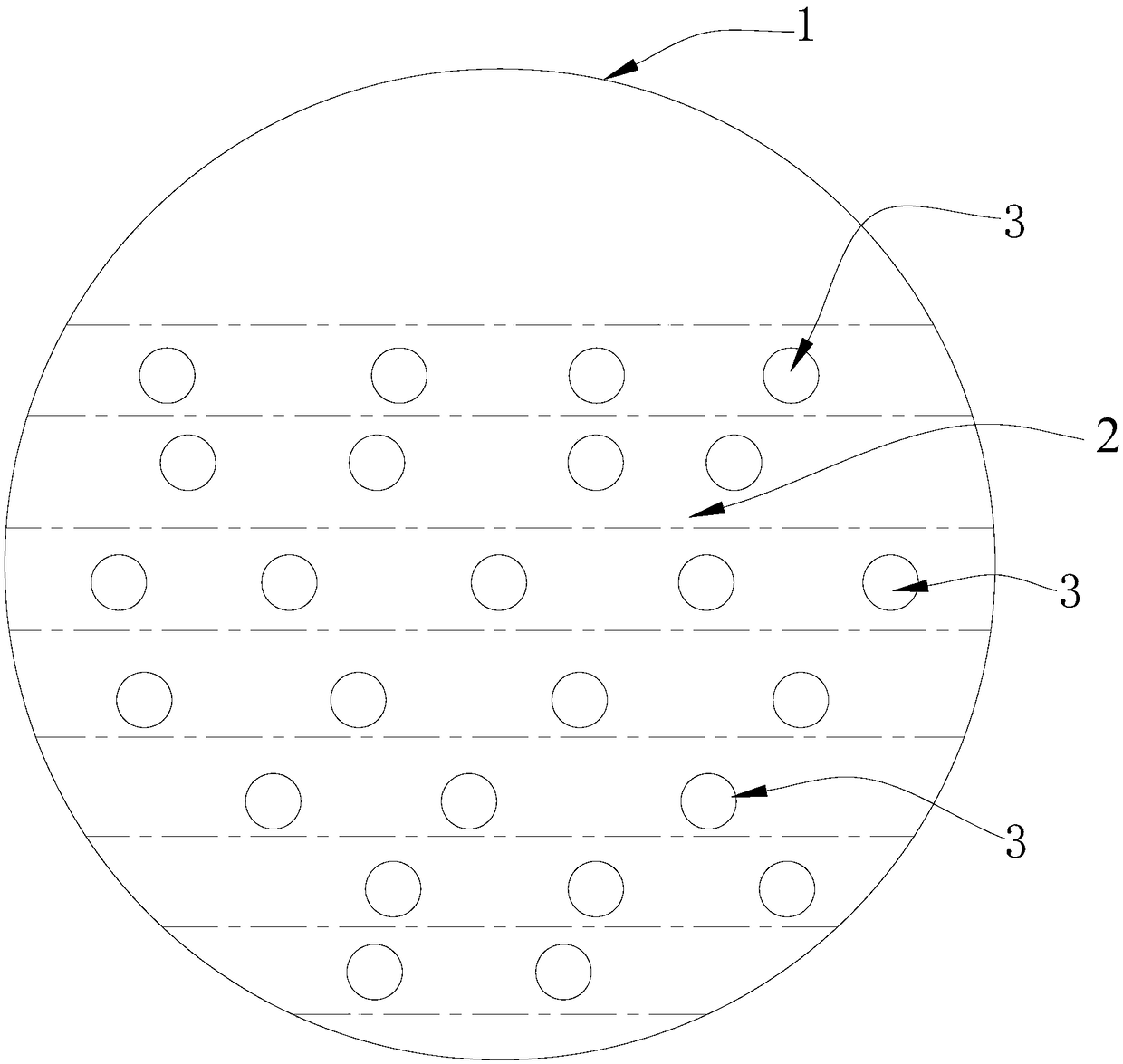

[0030] Such as figure 1 As shown, the present invention discloses a PCM energy storage structure capable of increasing the crystallization speed of phase change energy storage materials, which is provided with a sealed container 1 and a phase change energy storage material 2 stored in the sealed container 1. The phase change energy storage material 2 exchanges heat with the outside through the sealed container 1 .

[0031] The PCM energy storage structure is also provided with a plurality of crystal auxiliary cores 3 placed in the phase change energy storage material 2; the specific gravity of the crystal auxiliary core 3 is the same as that of the phase change energy storage material 2 in a liquid state The difference in specific gravity is within ±10%, the crystal auxiliary core 3 is made of a non-phase-change energy storage material, and the non-phase-change energy storage material satisfies the following characteristics: the thermal conductivity of the non-phase-change ene...

Embodiment 2

[0041] On the basis of the first embodiment above, the second embodiment also adopts the following preferred structure:

[0042] The auxiliary crystallization core 3 is provided with openings. Opening holes can be realized by a drilling machine, so that the area of non-uniform nucleation on the crystallization auxiliary core 3 can be further increased.

Embodiment 3

[0044] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred structure:

[0045] The crystallization auxiliary core 3 is made of a single non-phase-change energy storage material, the specific gravity of the single non-phase-change energy storage material is higher than that of the phase-change energy storage material 2 in a liquid state, and the crystallization auxiliary core 3 is provided with openings to reduce the specific gravity of the crystal auxiliary core 3 as a whole, so that the crystal auxiliary core 3 can be suspended in the liquid phase change energy storage material 2 .

[0046] Among them, preferably: the single non-phase-change energy storage material used in the auxiliary crystallization core 3 is cement.

[0047] Among them, preferably: the crystallization auxiliary core 3 is a cement sphere made of cement through a cement pelletizer. Therefore, the implementation of the present invention can...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap