Hole sealing device for blasting water injection in deep coal seam and blasting water injection method of device

A hole sealing device and coal seam water injection technology, which is applied in blasting, earthwork drilling, and discharge machinery, etc., can solve the problems such as poor dustproof effect of sealing yellow mud, non-recyclable sealing device, and inability to prevent electric sparks, etc. Achieve the effect of low material cost, ingenious design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

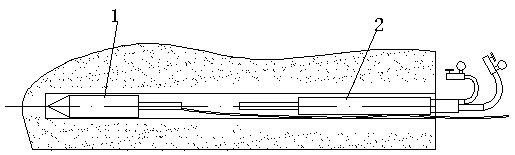

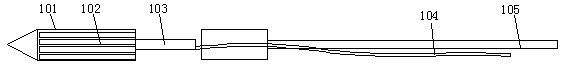

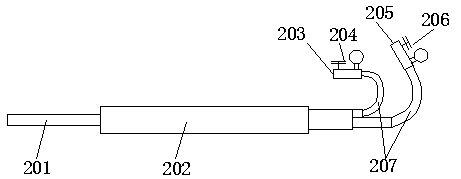

[0028] As shown in the figure, a hole sealing device for deep coal seam blasting and water injection includes a blasting mechanism 1 for blasting coal seams and a water injection hole sealing device 2 for sealing coal seam openings. 2. Detonate in a closed space with a structure to realize loose blasting of deep coal seams. The blasting mechanism 1 includes a charge storehouse 101 and an explosive 102 located in the charge storehouse 101, wherein the charge storehouse 101 is an inline cylindrical structure, and the charge storehouse 101 The front end is tapered to facilitate the insertion into the coal seam opening. The rear section of the drug storehouse 101 is provided with a cylindrical tail rod 103, and behind the tail rod 103, a drug feeder 105 is arranged. The drug feeder 105 withstands the tail rod 103 to The medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com