Frequency variance calculation and amplitude value operation combined vortex shedding flowmeter pipeline vibration resisting method and system

A vortex flowmeter, frequency variance technology, applied in the direction of volume/mass flow, measurement flow/mass flow, liquid/fluid solid measurement, etc. generated by mechanical effects, can solve the problem of incomplete phase synchronization, signal amplitude reduction, It is difficult to meet the sensitivity difference and other problems, and achieve the effect of low power consumption and small calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

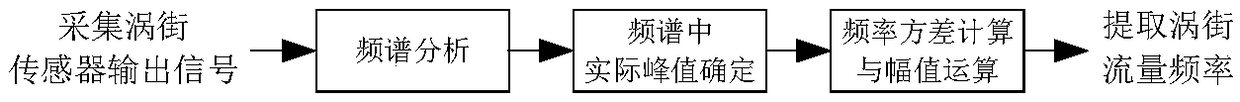

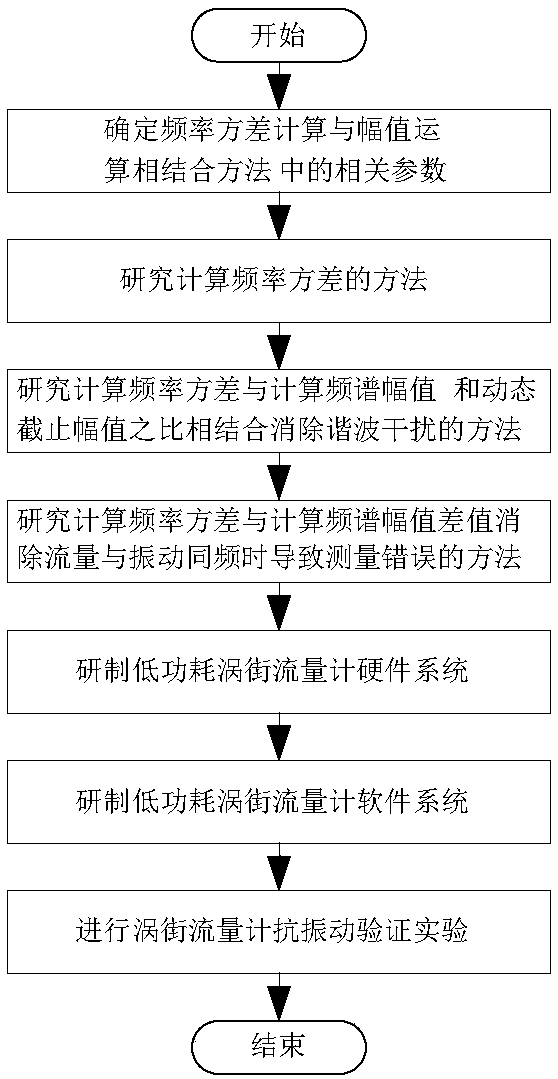

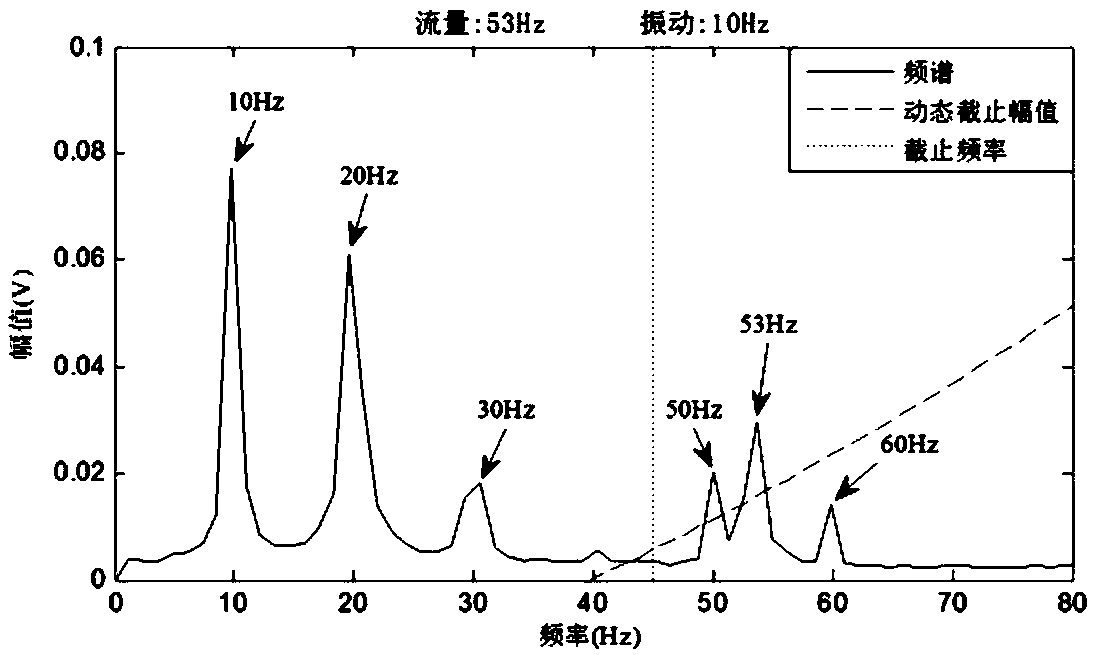

[0026] figure 1 It is a schematic diagram of the thinking of the method proposed by the present invention. Spectrum analysis is performed on the output signal of the vortex flow sensor, and then the peak value of the spectrum whose frequency and amplitude are both greater than the cut-off frequency and dynamic cut-off amplitude is extracted as the actual peak value. Since the flow signal of the vortex flow sensor is affected by flow noise such as turbulence, pulsation and flow field instability of the flow medium in the pipeline, its frequency will fluctuate near the ideal frequency, and the fluctuation is large. Therefore, the frequency variance of the flow signal Larger; vibration noise is mainly generated by electromechanical equipment such as motors, water pumps and valves, and its frequency tends to be fixed, so the fluctuation is small and the frequency variance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com