Connection rod structure-based cascade wind tunnel rotation window support mechanism

A cascade wind tunnel and connecting rod structure technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as increased manufacturing costs, difficulty in rotating windows, and expensive arc guide rails, etc., to achieve manufacturing The effect of simple process, reduced friction and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

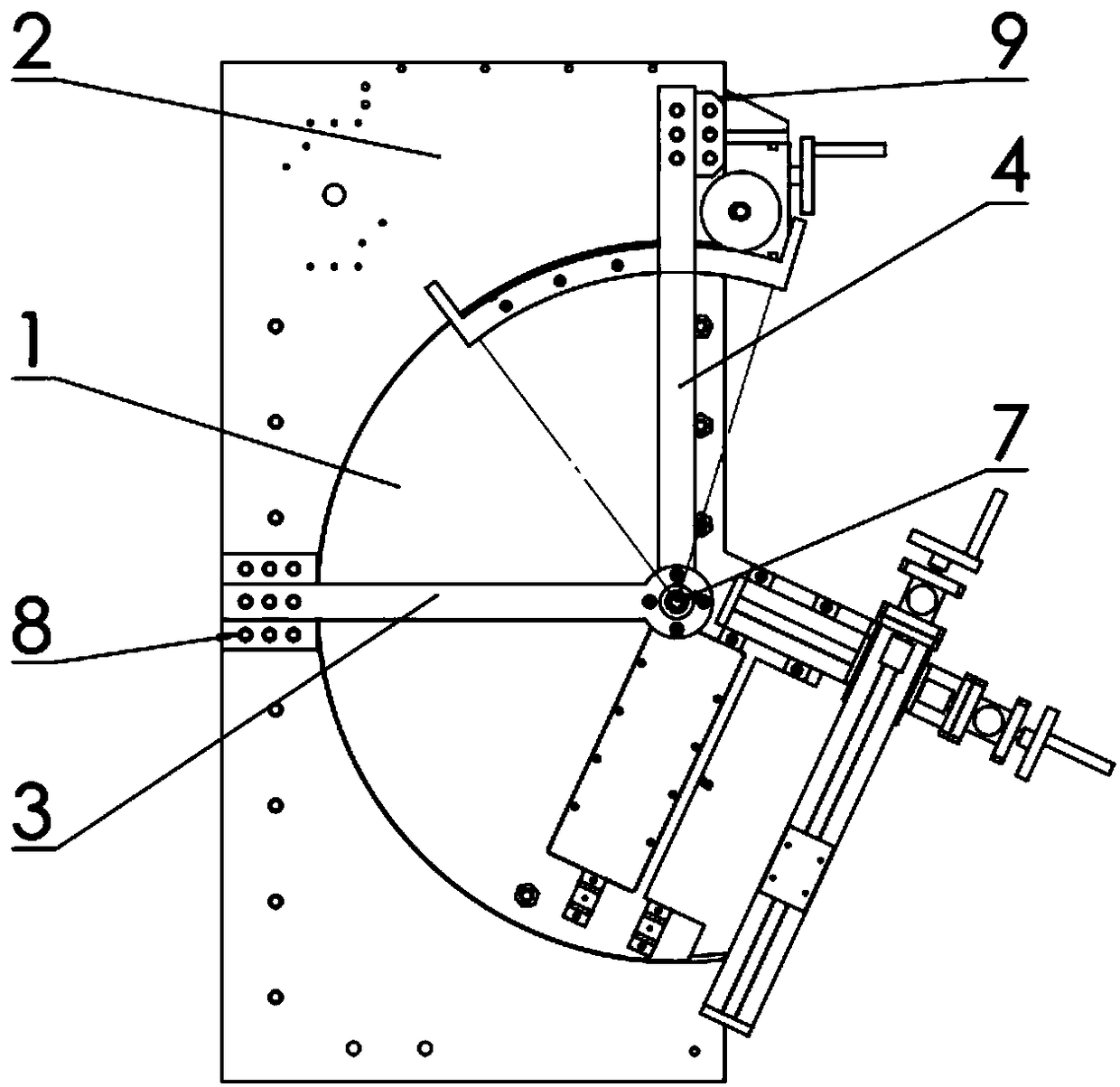

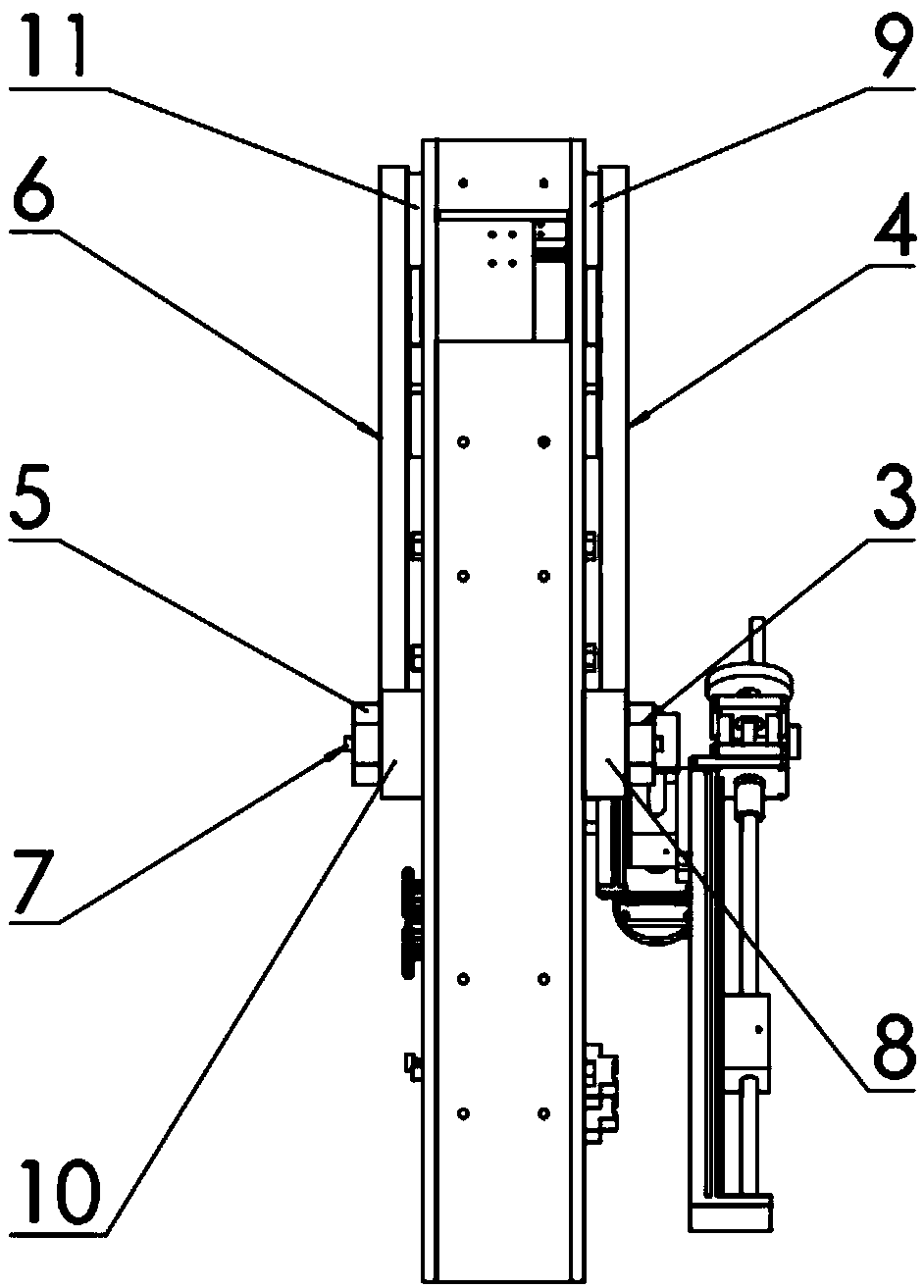

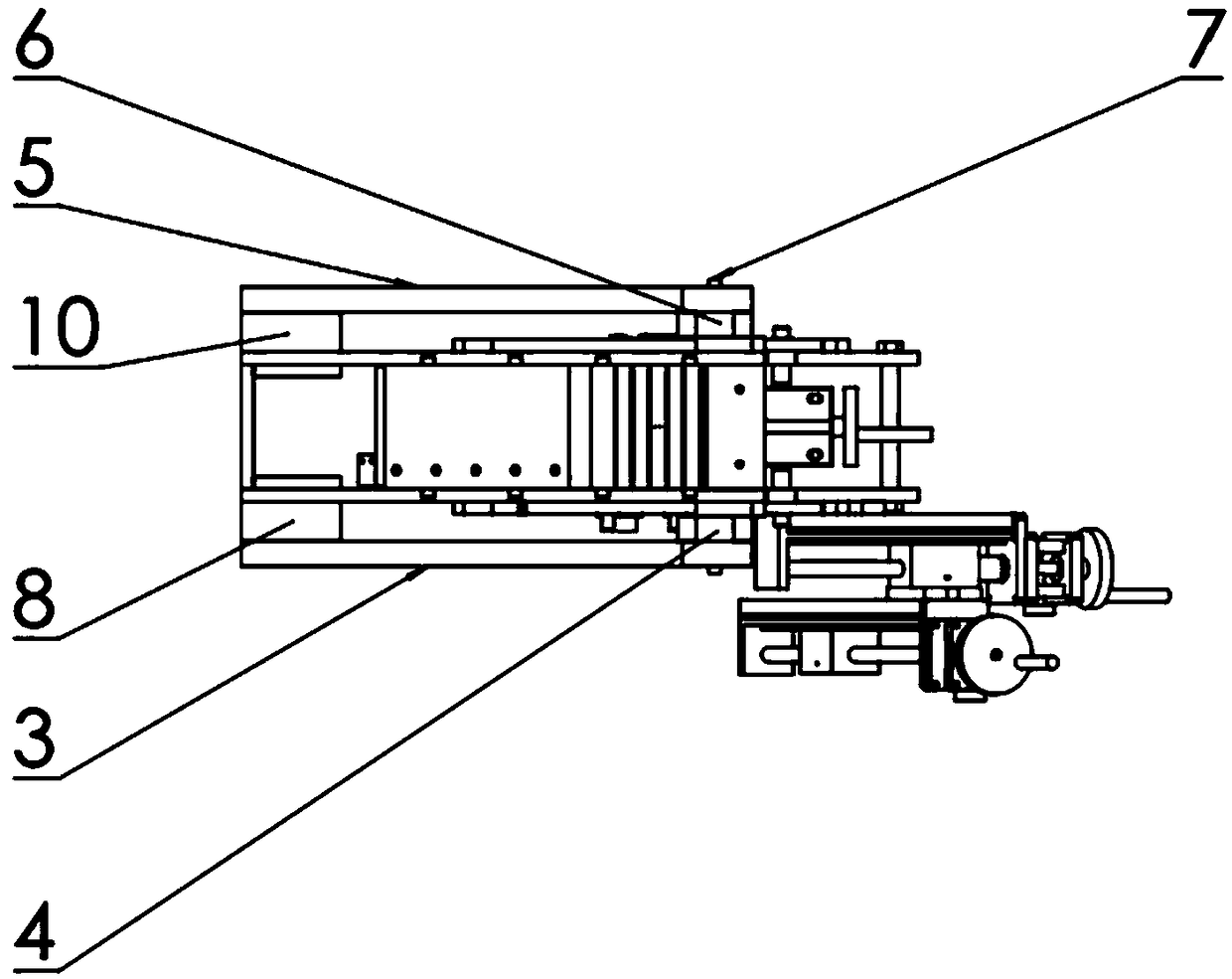

[0022] This implementation example is a support mechanism for a cascade wind tunnel rotating window based on a connecting rod structure.

[0023] refer to Figure 1 ~ Figure 4 , this implementation example is based on the cascade wind tunnel rotating window support mechanism of the connecting rod structure, consisting of the rotating window 1, the base 2, the first support beam 3, the second support beam 4, the third support beam 5, and the fourth support beam 6 , shaft 7, first liner 8, second liner 9, third liner 10, fourth liner 11; wherein, the turning window 1 is a fan-shaped flat plate, and the center of the two turning windows is provided with a center hole and a shaft 7 are connected, and two pairs of support beams are respectively arranged on both sides of the two turning windows, wherein the first support beam 3 and the third support beam 5 are horizontal, and the second support beam 4 and the fourth support beam 6 are vertical Towards. In this implementation examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com