Method for predicting fatigue crack growth of inner container of CNG2 gas bottle under burning environment

A technology of fatigue crack expansion and gas cylinders, which is applied in the field of CNG2 gas cylinders, can solve the problems of cylinder shaking, liner deformation, inconvenient collection of debris, etc., and achieve the effect of increasing the vibration amplitude, improving the accuracy of the experiment, and preventing shaking

Inactive Publication Date: 2019-01-18

汕头职业技术学院

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

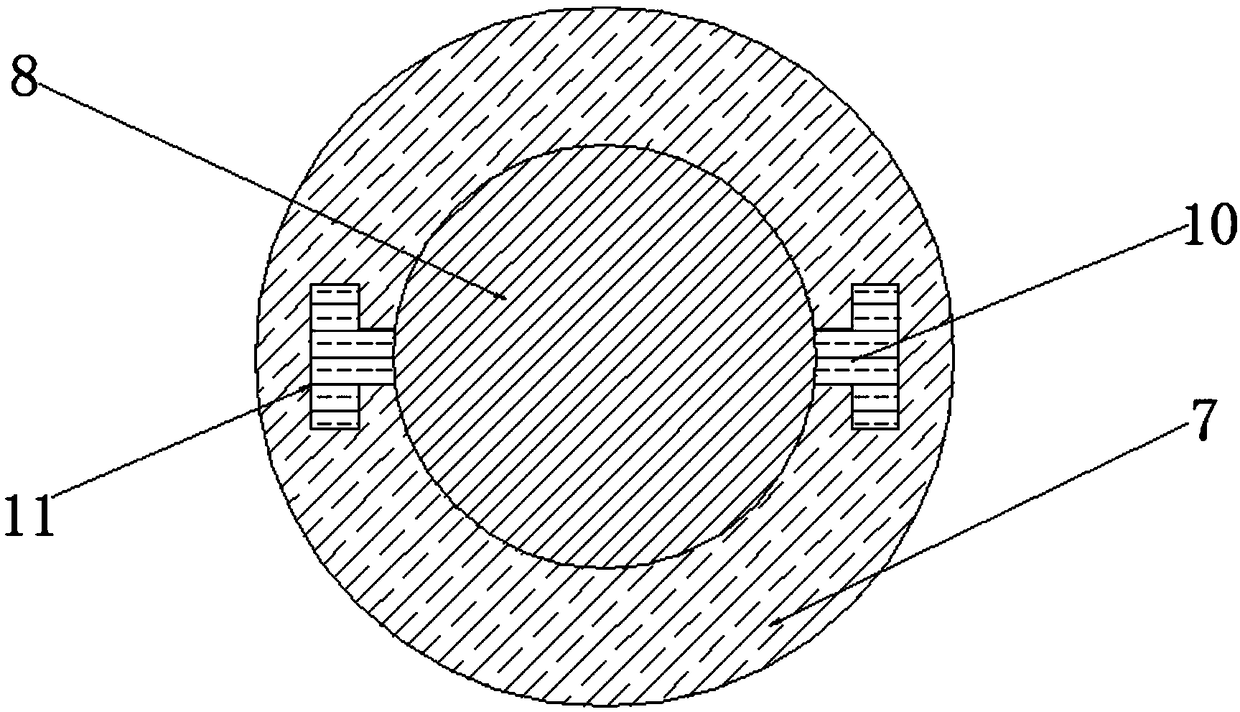

[0003] However, the general method for predicting the fatigue crack growth of CNG2 gas cylinder liner in a fire environment has the following defects: the gas cylinder in a high temperature environment undergoes plastic deformation under the action of internal pressure, and the gas cylinders that have experienced different filling and deflation times have different The growth rate and form of fatigue cracks are not yet clear. It is difficult to predict the structural integrity of the CNG2 gas cylinder liner under fire conditions, and related problems need to be resolved. During the fatigue test of filling and deflation of gas cylinders, the gas cylinders are prone to shaking It is not convenient for the staff to operate the gas cylinder, and at the same time, when the wire cutting is performed on the tensile test sample, the debris generated during cutting is not easy to collect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] A method for predicting the expansion of fatigue cracks in the CNG2 gas cylinder liner in a fire environment, comprising the following steps;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

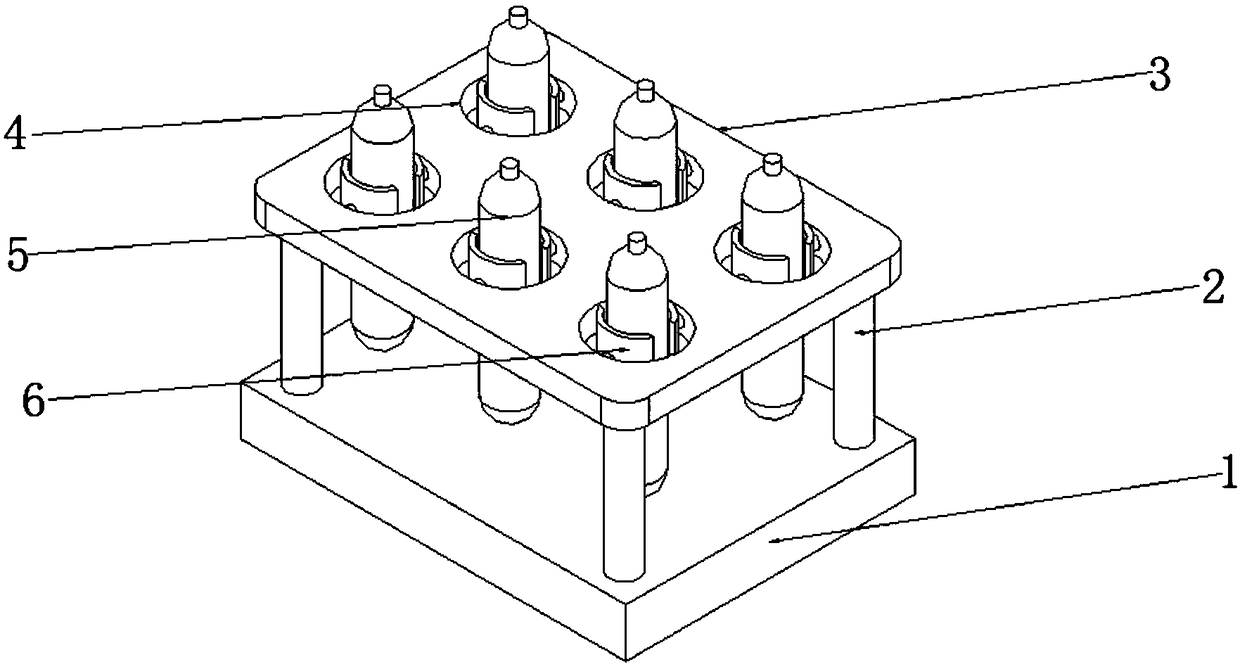

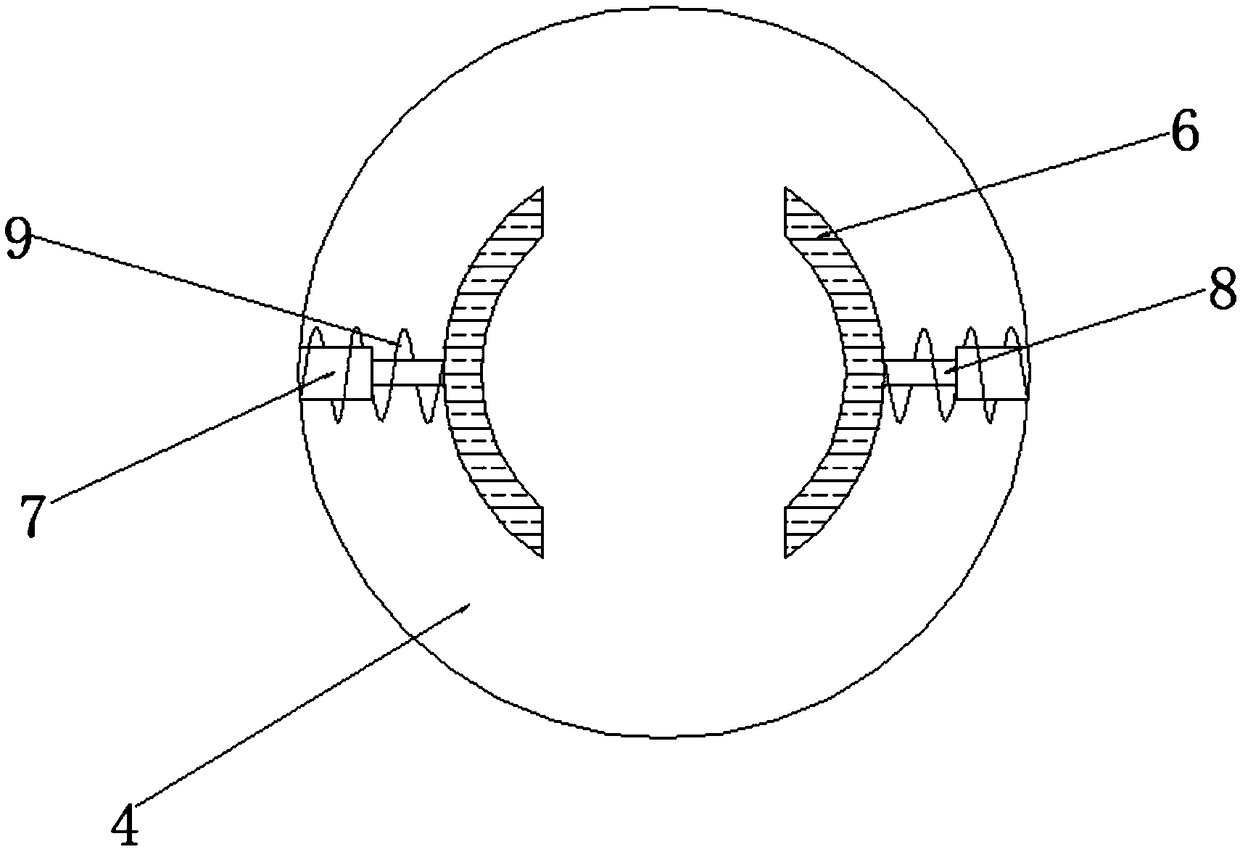

The invention discloses a method for predicting fatigue crack growth of an inner container of a CNG2 gas bottle under a burning environment. The method comprises the following steps: 1, placing a plurality of CNG2 gas bottles in a fixed device, and performing inflation and deflation fatigue test for the CNG2 gas bottles, using a gas bottle pressure circulating test device, wherein test medium is hydraulic oil, circulating pressure lower limit is 2MPa, circulating pressure upper limit is 30 MPa, pressurization circulating rate is 6 times / minute, and after circulating inflation and deflation times respectively reach test ruled times 5000, 10000, 15000 and 20000, the inflation and deflation fatigue test is finished. In the method, a cylindrical barrel segment circumferential original sample is cut, the sample is processed into a stretching sample, a 8000 DEG C high temperature creep and stress rupture test is executed, the sample is downloaded 20 minutes later, and the sample is further processed into a metallographic phase sample, meanwhile, a barrel slice which is not subjected to high temperature test is processed into the metallographic phase sample, the two types of metallographic phase samples are observed under a field scan electron microscope (SEM), and a comparative test is executed for improving test precision.

Description

technical field [0001] The invention relates to the technical field of CNG2 gas cylinders, in particular to a method for predicting the expansion of fatigue cracks in the inner tank of CNG2 gas cylinders in a burning environment. Background technique [0002] As the number of filling and deflation of CNG2 gas cylinders for vehicles increases, due to the accumulation of microscopic cyclic plastic strain damage, fatigue crack initiation and propagation will occur in the barrel section of the metal liner. The research on the fatigue life of CNG2 gas cylinders under normal working conditions and Some research results have been obtained on the microscopic fatigue damage mechanism of the metal liner. However, there are few related studies on fire conditions. When a gas vehicle fires, the general burning time is about 40 minutes. It is lower than 300°C within 20 minutes, and reaches 800°C in 20-40 minutes. The fiber layer wrapped around the cylinder section of the CNG2 gas cylinder...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/36G01N3/18

CPCG01N3/18G01N3/36G01N2203/0071G01N2203/0641

Inventor 谢志刚陈小芹卢旭锦余阿陵方迪成

Owner 汕头职业技术学院

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap