panel structure

A panel and substrate technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems affecting the reliability of display panels, non-rectangular panel cutting cracks, performance degradation, etc., to improve resistance to external moisture Ability to invade, reduce cracking and/or flaking spots, increase the effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

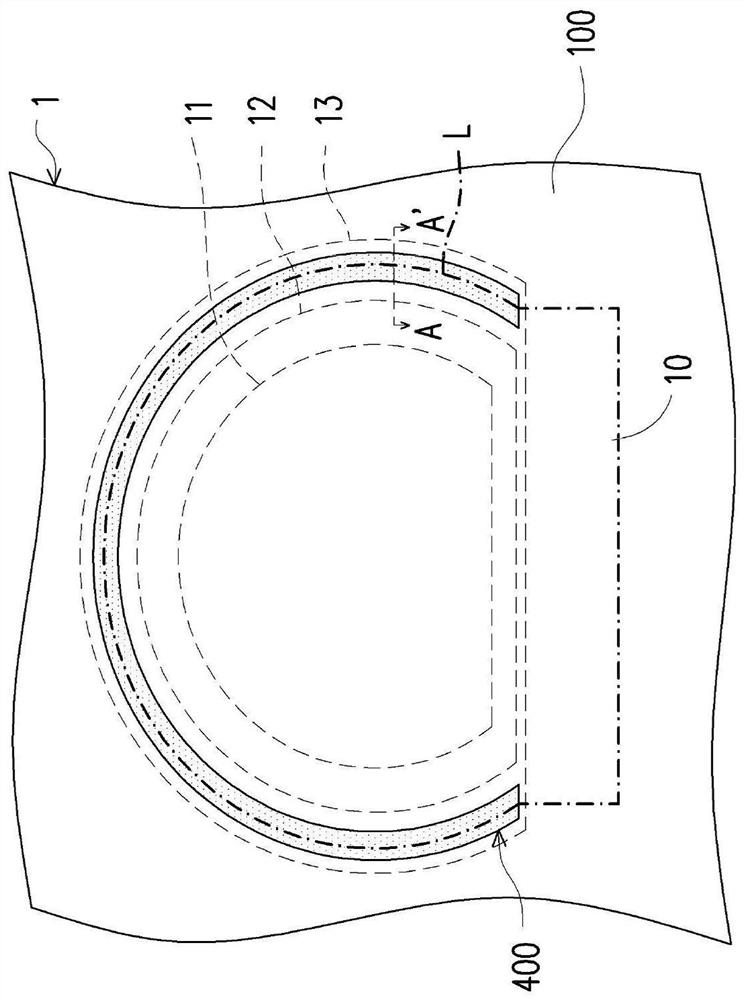

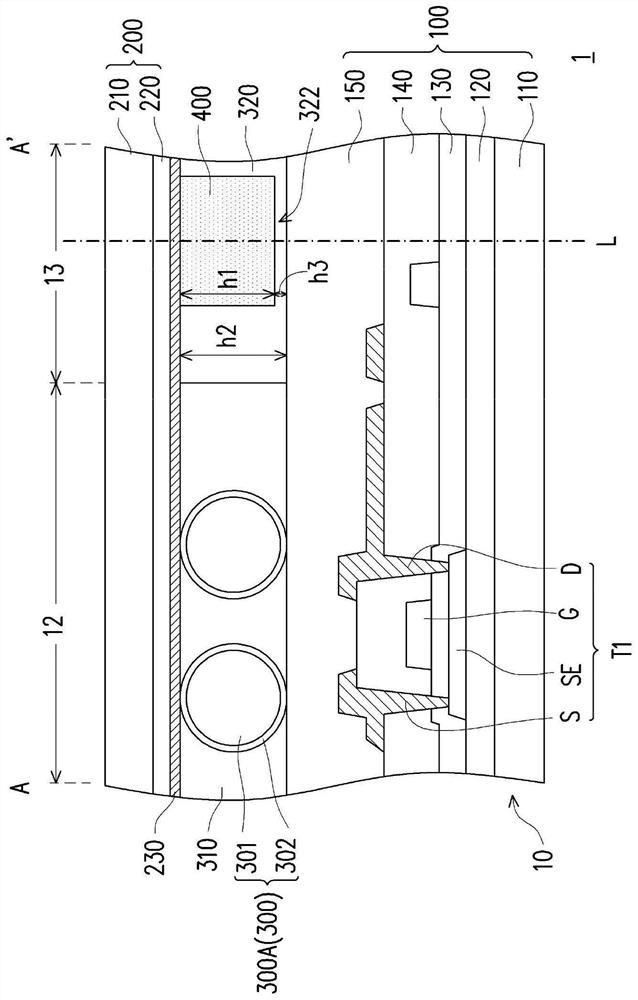

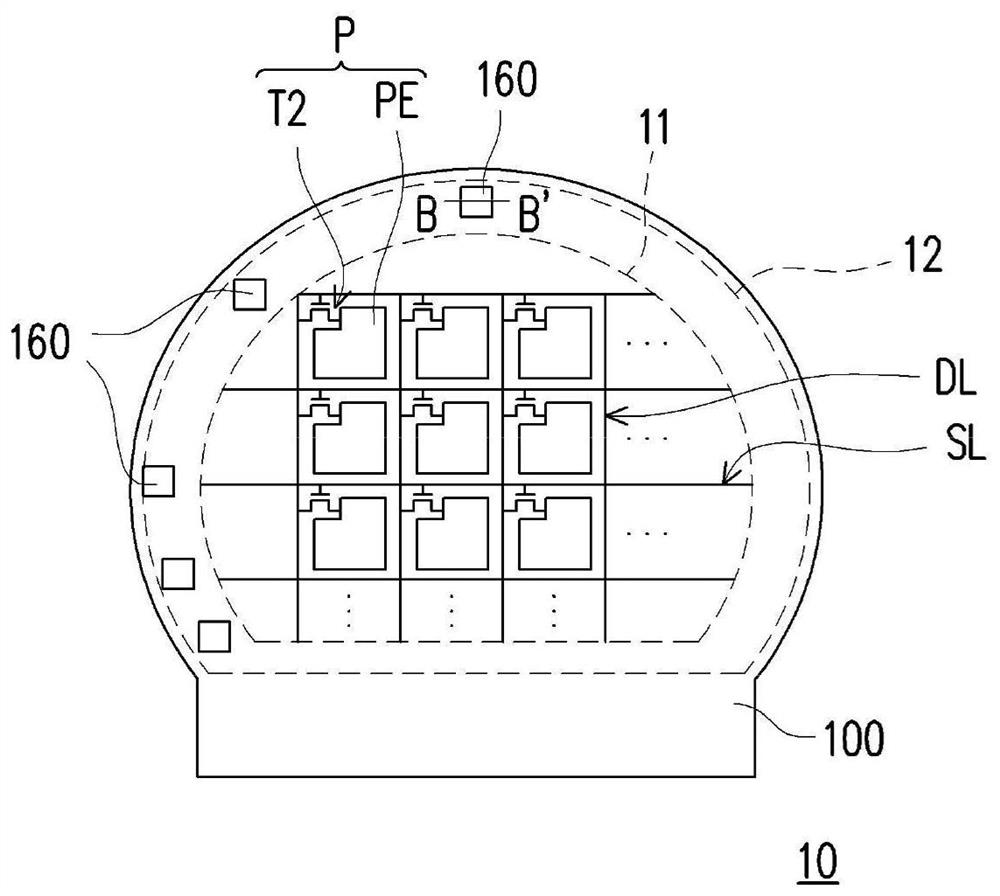

[0060] figure 1 Shown is a top view of a motherboard of an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the motherboard 1 includes a first substrate 100 and a second substrate 200 opposite to the first substrate 100 (shown in figure 2 ), and includes a plurality of panel structures 10 that have been prepared but not yet cut. The uncut panel structure 10 has a display area 11, a first peripheral area 12, a second peripheral area 13 and a cutting line L. Specifically, the motherboard 1 is the first substrate 100 and the second substrate 200 that have not undergone a cutting process. It should be noted that, for the convenience of explanation and observation, figure 1 Omit drawing some components. The following embodiments will take some components disposed on the first substrate 100 as an example, but the present invention is not limited thereto. In other embodiments, figure 1 The components shown can also be disposed on the second s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com