A square battery cell group of an energy storage battery module

A technology for energy storage battery modules and square cells, which is applied in small-sized batteries/battery packs, large-sized batteries/battery packs, battery pack components, etc. It can improve reliability and safety, prevent expansion and deformation, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

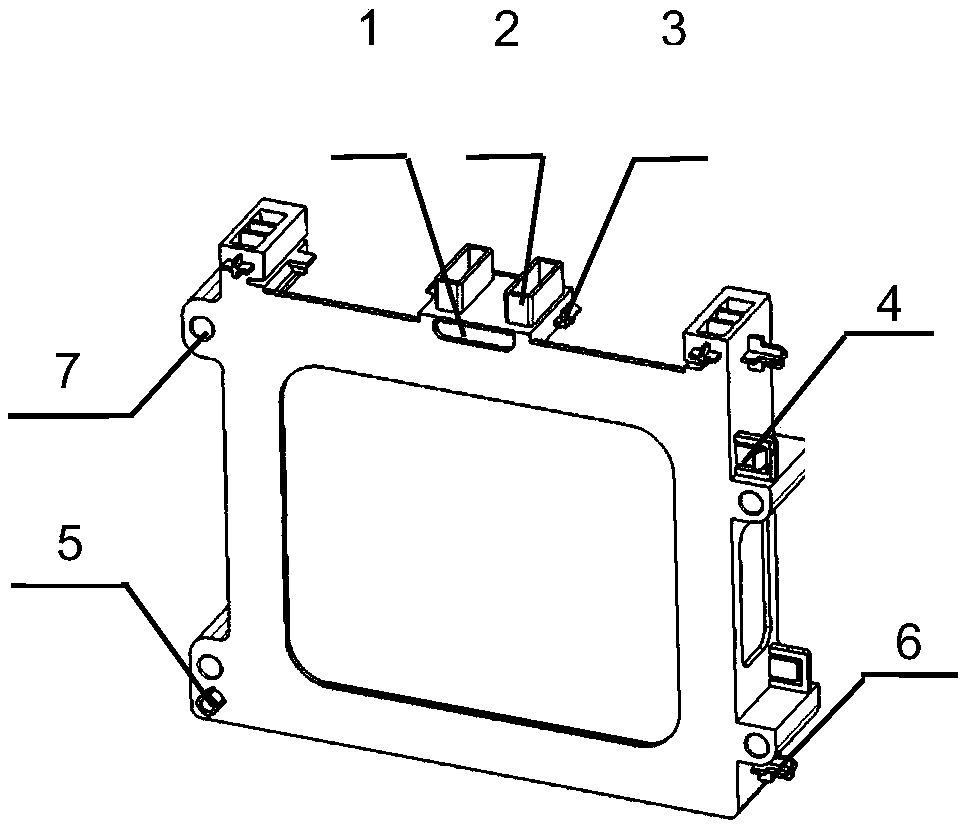

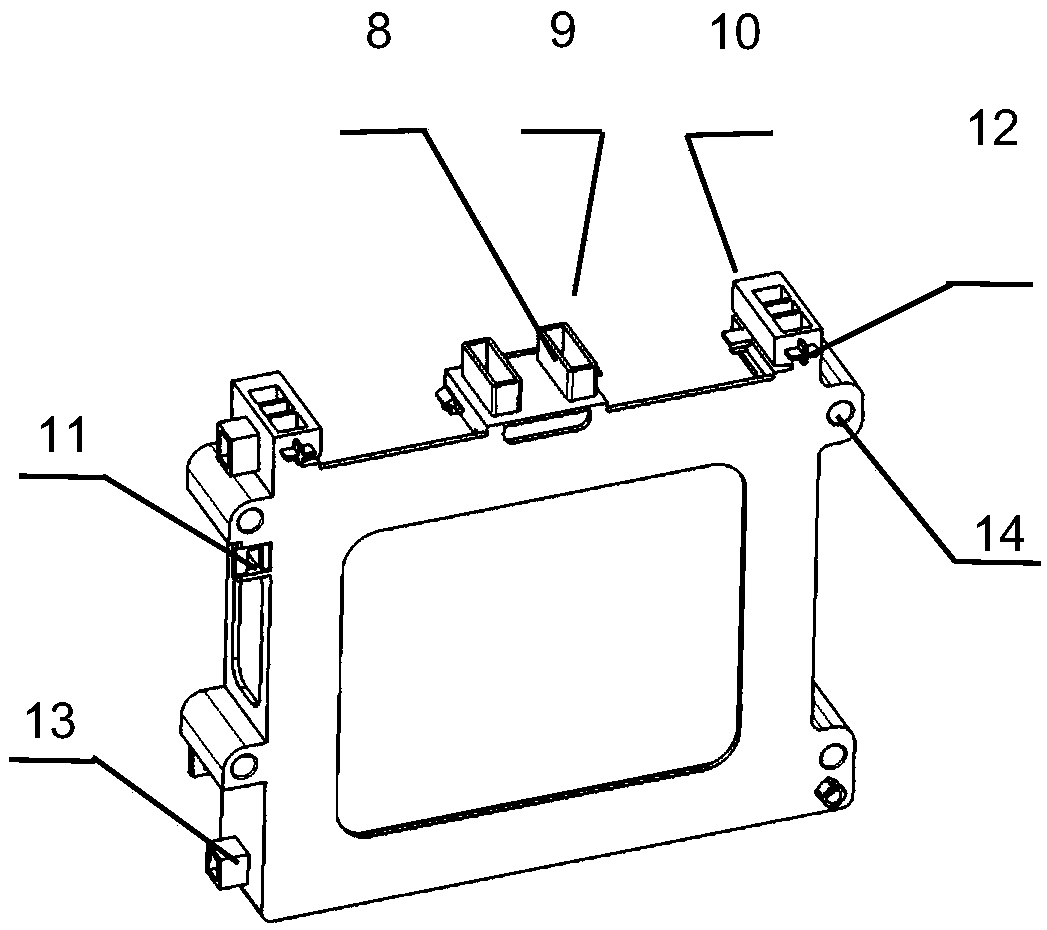

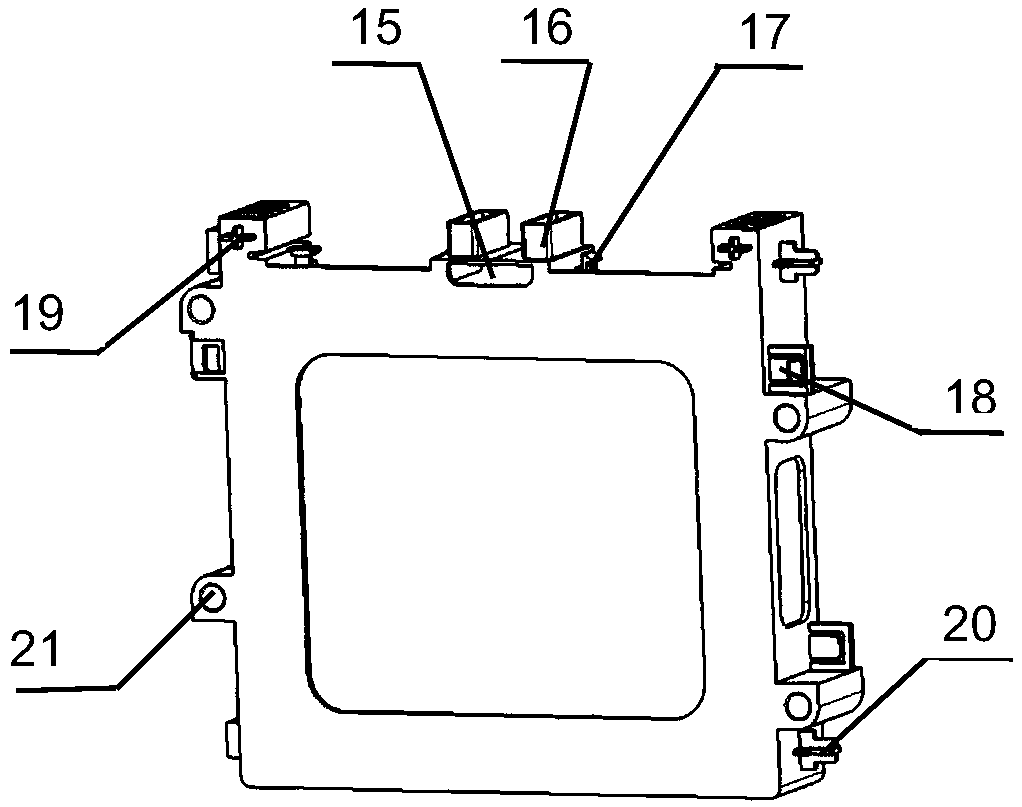

[0021] Such as Figure 7 As shown, the schematic diagram of 16 rows and 2 rows of combined battery module units, the square cells of the energy storage battery module are grouped with three kinds of plastic brackets, which are universal left bracket, universal right bracket, and universal middle bracket; The plastic bracket can be combined with the square battery alone to form a battery unit. After the three battery units are combined with each other, the horizontal expansion and vertical expansion of the battery unit can be realized; the longitudinal expansion is assembled by a long screw to form 16 rows. As for the cell combination unit, the horizontal expansion is assembled through the horizontal buckles on three kinds of plastic brackets to form 2 rows of cell combination units, and finally form 16 rows of 2 rows of cell combination units. The universal left bracket (such as figure 1 As shown) is provided with the first air vent 1 between the plastic brackets, the first p...

Embodiment 2

[0025] Such as Figure 8 As shown, in the 12-row and 4-column battery module combination unit, the square cells of the energy storage battery module are grouped with three kinds of plastic brackets, which are the universal left bracket, the universal right bracket, and the universal middle bracket; The plastic bracket can be combined with the square battery alone to form a battery unit. After the three battery units are combined with each other, the horizontal expansion and vertical expansion of the battery unit can be realized; the longitudinal expansion is assembled through a long screw to form 12 rows. As for the cell combination unit, the horizontal expansion is assembled through three kinds of horizontal buckles on the plastic brackets to form 4 rows of cell combination units, and finally form 12 rows of 4 rows of cell combination units. The universal left bracket (such as figure 1 As shown) is provided with the first air vent 1 between the plastic brackets, the first pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com