Modular battery pack

A battery pack and power technology, applied in battery pack components, batteries, secondary batteries, etc., can solve the problems of shortened battery life, increased safety hazards, and short service life of lead-acid batteries. It is convenient for assembly and on-site construction, reduces the oxidation of the connecting piece, and improves the safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

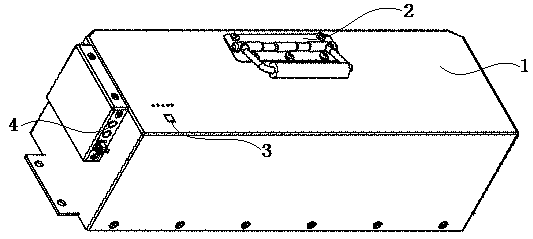

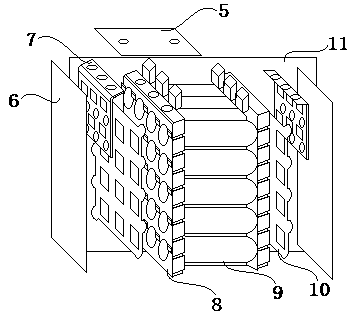

[0017] Such as figure 1 , figure 2 A modular battery pack is shown, including a sheet metal box 1, a handle 2, a power indicator 3, a protective top cover 5, an insulating plate 6, a fixing bracket 8, a battery pack 9 and a cushion 11.

[0018] Such as figure 1 As shown, the handle 2 is connected to the side of the sheet metal box 1, and a power indicator 3 is provided on the side where the handle 2 is located. combine figure 1 , figure 2 As shown, the protective top cover 5, the insulating plate 6, the fixed bracket 8 and the battery pack 9 are connected to the inside of the sheet metal box 1, the protective top cover 5 is connected to the upper wall of the sheet metal box 1, and the insulating plate 6 is connected to the On both sides of the sheet metal box 1, the insulating boards 6 are epoxy resin boards, and there are at least two.

[0019] The opposite surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com