An ultra-low particle size lead power extraction device

An extraction device, lead powder technology, applied in lead-acid batteries, electrode manufacturing, electrical components, etc., can solve problems such as limited electricity storage performance, large gap in lead powder particle size, and lead-acid battery capacity limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

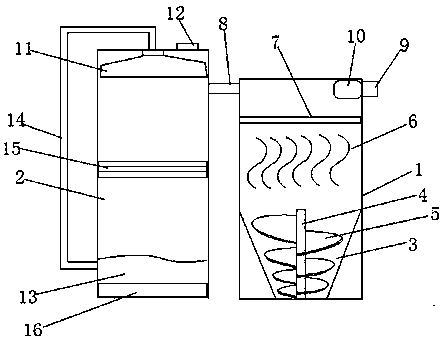

[0016] Such as figure 1 As shown, a kind of ultra-low particle size lead powder extracting device of the present invention comprises interconnected particle suspension bin 1 and particle capture bin 2, and particle suspension bin 1 is used for raising the lead powder particles of small particle size, only needs The part of the lead powder suspended particles flying in the uppermost layer, and the particle capture bin 2 is used to collect the lead powder suspended particles.

[0017] The bottom of the particle suspension bin 1 is a lead powder drop-in area 3, and the central position of the lead powder drop-in area 3 is provided with a central rotating shaft 4, and the central rotating shaft 4 is provided with a spiral blade 5, and the top of the lead powder drop-in area 3 is provided with a The particle flow layer 6, the particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com