A charging gun for fast charging of high-protection electric vehicles

An electric vehicle and fast charging technology, applied in the field of charging rush, can solve the problems of insulation protection for people who cannot operate, low insulation protection level, and fires, etc., to improve flexibility and convenience, improve safety and reliability, and achieve The effect of insulating isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

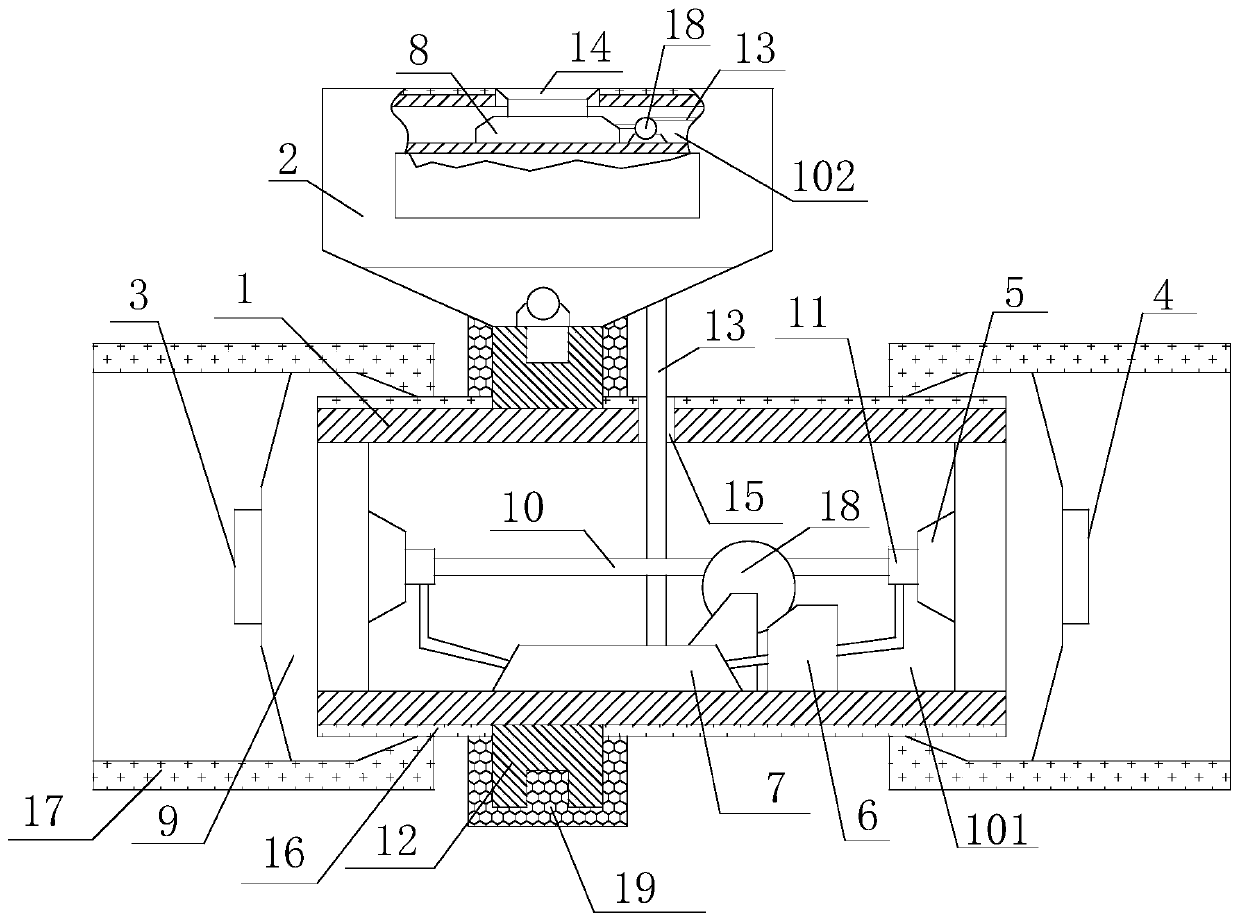

[0017] Such as figure 1 The charging gun for fast charging of high-protection electric vehicles includes a gun body 1, a grip handle 2, a wiring plug 3, a charging plug 4, a current-limiting fuse 5, an overload protection circuit 6, a charging and discharging controller 7, and Integrated control circuit 8. The gun body 1 has a hollow tubular structure, and its front and rear ends are both provided with insulating sealing ends 9. The insulating sealing ends 9 cover the front and rear surfaces of the gun body 1 and form a hermetic seal with the gun body 1. In the charging chamber 101 of the cavity structure, the wiring plug 3 is embedded in the outer surface of the insulating sealed end 9 on the rear surface of the gun body 1, and the charging plug 4 is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com