An optimal design method of axially phase-separated magnetic suspension switched reluctance flywheel motor

A flywheel motor and switched reluctance technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems that the flywheel energy storage cannot be guaranteed to obtain the optimal comprehensive performance and the motor is complicated to operate, so as to avoid the dimensional disaster. , Improve the optimization accuracy and optimization efficiency, the effect of accurate modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

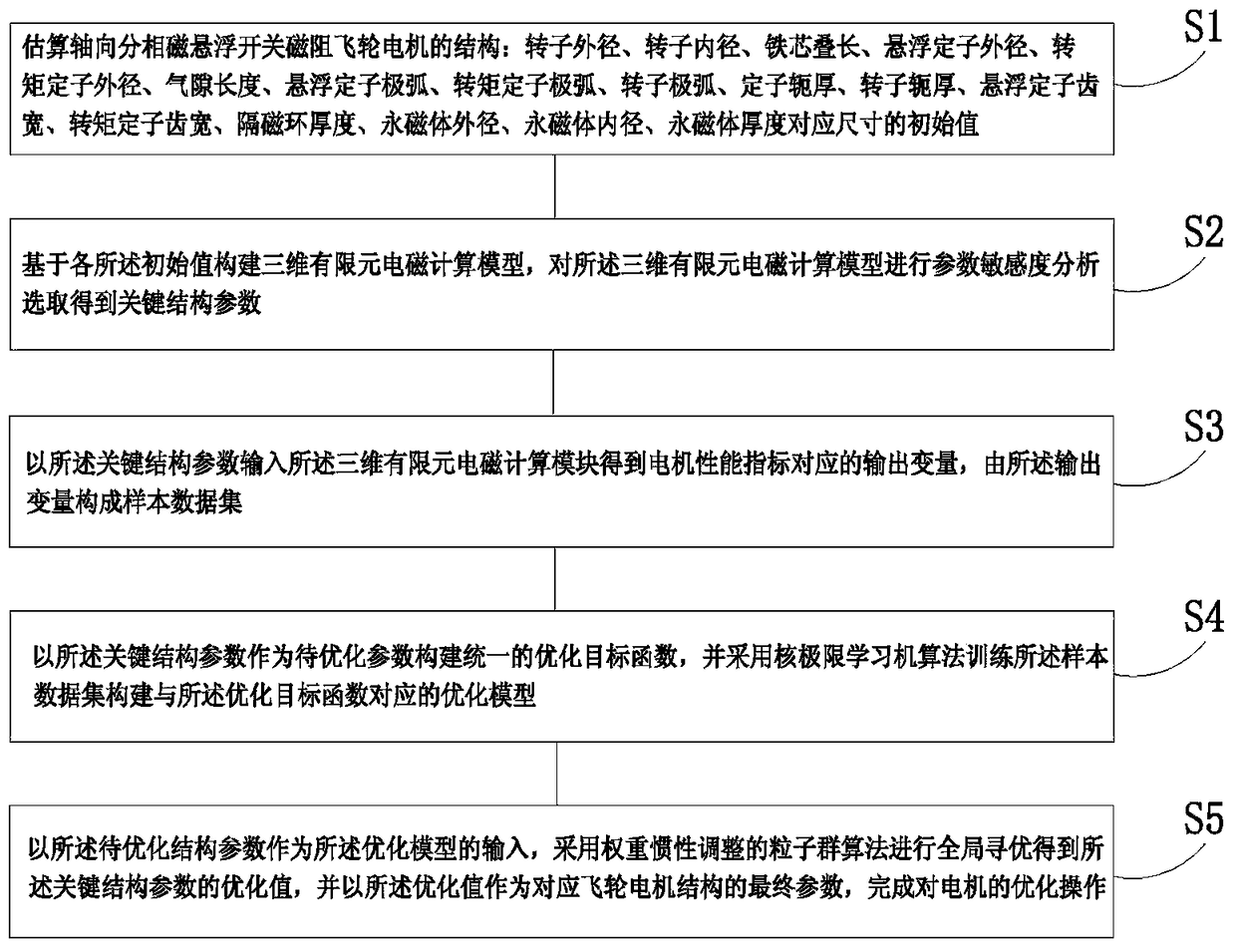

[0048] refer to figure 1 , in an embodiment of the present invention, a method for optimal design of an axial phase-splitting magnetic levitation switched reluctance flywheel motor is provided, the method comprising the steps of:

[0049] S1. Estimating the structure of the axial split-phase magnetic levitation switched reluctance flywheel motor: rotor outer diameter, rotor inner diameter, iron core stack length, suspended stator outer diameter, torque stator outer diameter, air gap length, suspended stator pole arc, torque The initial value of stator pole arc, rotor pole arc, stator yoke thickness, rotor yoke thickness, suspended stator tooth width, torque stator tooth width, magnetic isolation ring thickness, permanent magnet outer diameter, permanent magnet inner diameter, and permanent magnet thickness is :

[0050] D. a0 ,D i0 , l a0 ,D sw0 ,D sn0 , g 0 ,β sw0 ,β sn0 ,β r0 ,h cs0 ,h cr0 ,b sw0 ,b sn0 ,h ms ,D pma0 ,D pmi0 , l pm0 ;

[0051] Specifically...

Embodiment 2

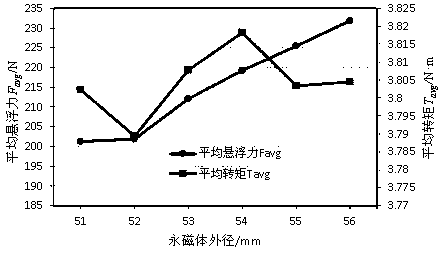

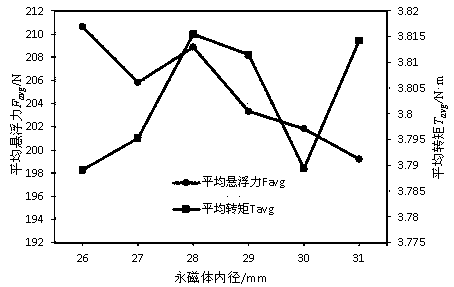

[0065] Combined with Figure 2~ Figure 10 The optimal design method of the axial phase-splitting magnetic levitation switched reluctance flywheel motor in the first embodiment will be described in detail.

[0066] First, set the predetermined performance parameters of the flywheel motor as: rated power P N =3kW, rated speed n N =2000r / min, rated voltage U N =220V, rated efficiency η=0.8, according to the traditional calculation method of the structural parameters of the switched reluctance motor and the existing design experience, the initial value of the structural parameters of the axial split-phase magnetic levitation switched reluctance flywheel motor is: the outer diameter of the rotor D a0 =130mm, stator outer diameter D sn0 =103.4mm, inner diameter of rotor D i0 =104mm, suspension pole yoke thickness h csw0 =6mm, torque pole yoke thickness h csn0 =8.5mm, rotor yoke thickness h cr0 =6mm, air gap length g 0 =0.3mm, floating pole arc β sw0 =30°, torque polar arc β...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com