Horizontal drying chamber

A drying chamber and horizontal technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of processing heat dissipation area, large internal volume, increase energy consumption, etc., and achieve fan power reduction, The effect of reducing the internal volume and reducing the overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

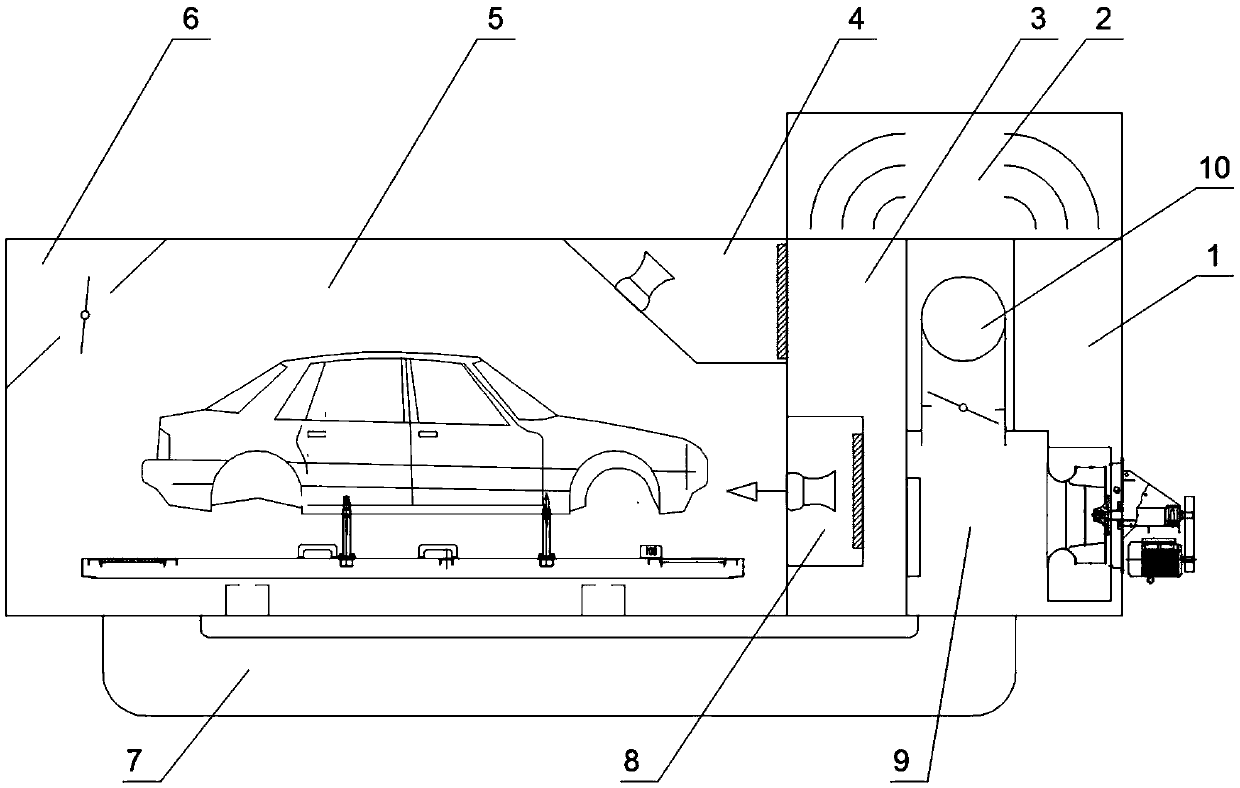

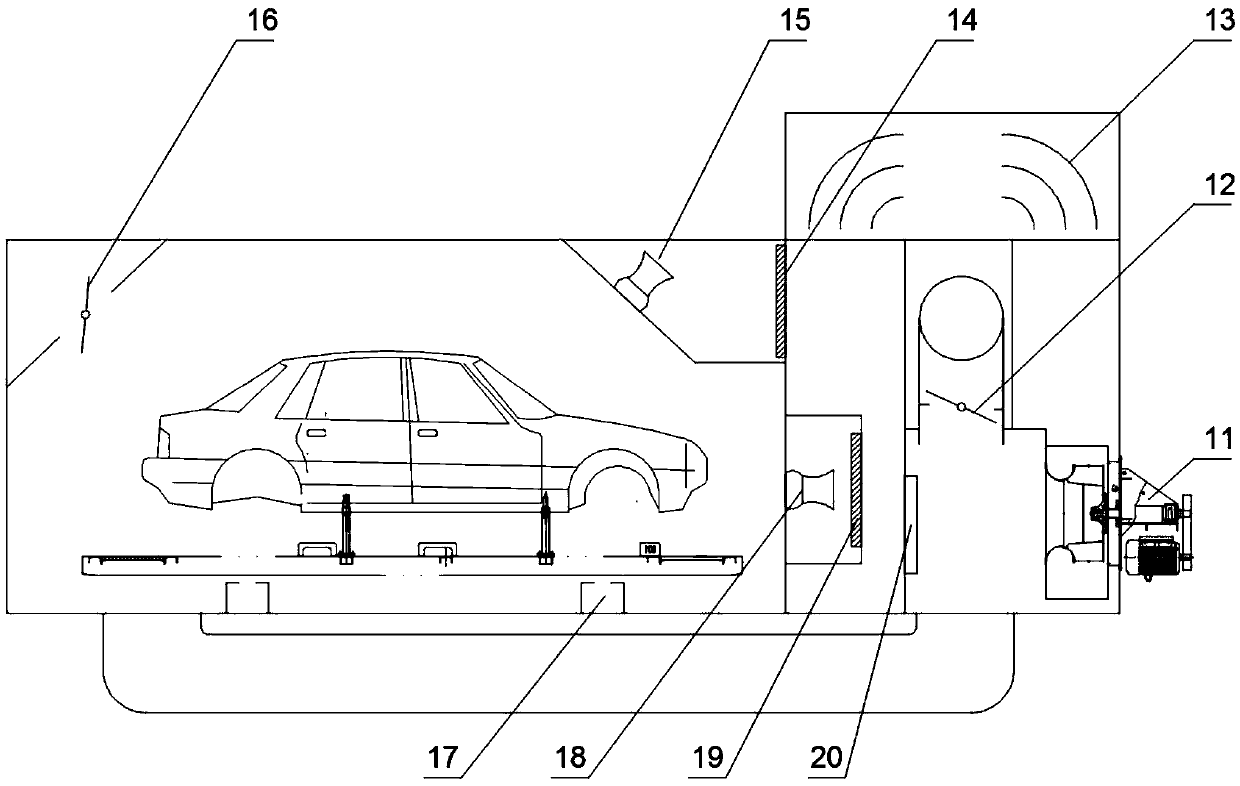

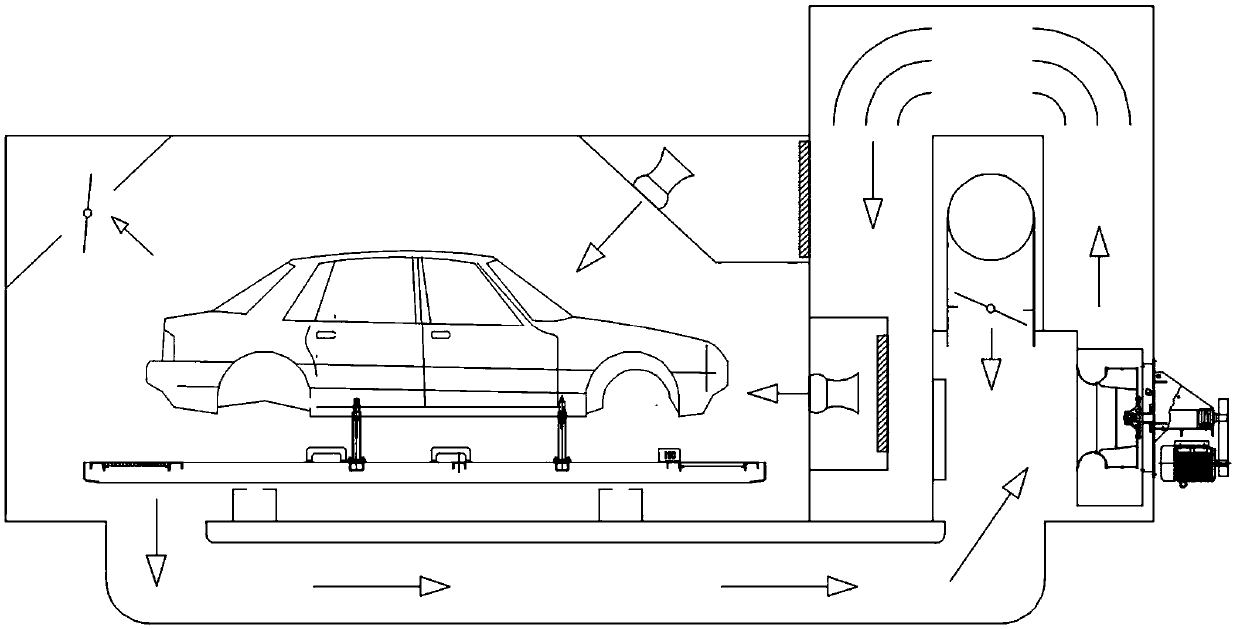

[0024] see Figure 1-3 As shown, a horizontal drying chamber includes a drying channel 5 for the lateral movement of the vehicle. One side of the drying channel 5 in the axial direction forms a side inner air channel 8, and the upper side of the side inner air channel A roof air channel 4 is formed at the corner of the drying channel 5, an exhaust air channel 6 is formed at the corner of the drying channel on the opposite side of the roof inner channel, and the bottom of the drying channel is set There is a bottom return air channel 7, which communicates with the air mixing chamber 9 located outside the side inner air channel; a high temperature air channel 10 for introducing high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com