Vacuum pipeline self-cleaning control system for continuous multi-station polishing machine

A vacuum pipeline and control system technology, which is applied in the direction of surface polishing machine tools, grinding automatic control devices, grinding/polishing equipment, etc., can solve problems such as troublesome operation, complicated vacuum pipelines, and pipeline blockages, so as to save materials, The effect of reducing production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

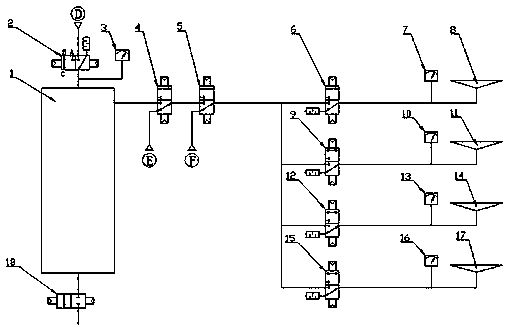

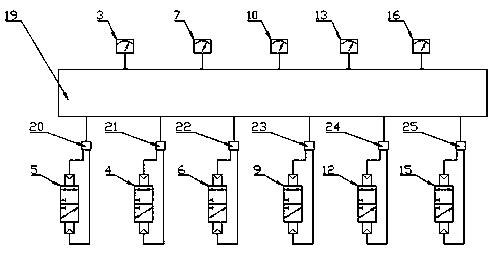

[0026] refer to figure 1 and figure 2 , a self-cleaning control system for the vacuum pipeline of a continuous multi-station polishing machine, including a vacuum gas storage tank 1, a pneumatic three-way ball valve I2, an air pressure sensor I3, a pneumatic three-way ball valve II4, a pneumatic three-way ball valve III5, and a pneumatic three-way Ball valve Ⅳ6, air pressure sensor Ⅱ7, polishing disc Ⅰ8, pneumatic three-way ball valve Ⅴ9, air pressure sensor Ⅲ10, polishing disc Ⅱ11, pneumatic three-way ball valve Ⅵ12, air pressure sensor Ⅳ13, polishing disc Ⅲ14, pneumatic three-way ball valve Ⅶ15, air pressure Sensor Ⅴ16, polishing disc Ⅳ17, pneumatic two-way ball valve 18, programmable controller 19, solenoid valve Ⅰ20, solenoid valve Ⅱ21, solenoid valve Ⅲ22, solenoid valve Ⅳ23, solenoid valve Ⅴ24 and solenoid valve Ⅵ25;

[0027] The top of the vacuum gas storage tank 1 is connected to the pneumatic three-way ball valve I2 and the air pressure sensor I3 through pipelines, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com