Ultra-thin plate vacuum pumping adsorption device

An adsorption device and vacuum pumping technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., to achieve the effect of preventing scratches, simple structure, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

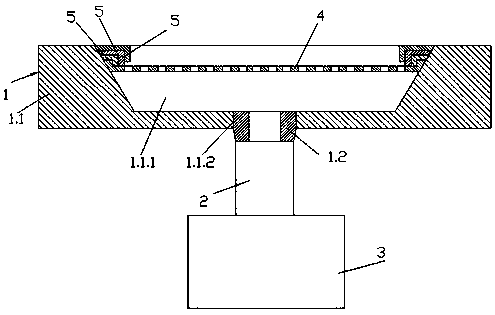

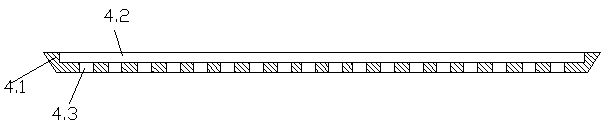

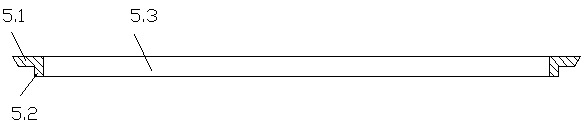

[0018] Embodiment 1: A vacuum suction device for ultra-thin plates, including a suction plate 1, a vacuum pipeline 2 and a vacuum pump 3, the suction plate 1 includes a square base 1.1, a vacuum chamber 1.1.1 set on the surface of the square base 1.1, the vacuum chamber 1.1.1 The cross-section is a trapezoidal square hole, the center of the bottom surface of the vacuum chamber 1.1.1 is provided with a vacuuming through hole 1.1.2, the inner seal of the vacuuming through hole 1.1.2 is connected with a vacuuming nozzle 1.2, and the vacuuming nozzle 1.2 is connected to a vacuum pipe 2. The vacuum pipeline 2 is connected to the vacuum pump 3, and the first vacuum bracket 4 is erected inside the vacuum chamber 1.1.1, and the first vacuum bracket 4 includes a substrate 4.1 that cooperates and seals with the side wall of the vacuum chamber 1.1.1 1. The first adsorption cavity 4.2 opened on the substrate 4.1 for placing the plate and the adsorption holes 4.3 opened on the bottom surfac...

Embodiment 2

[0019] Embodiment 2: Referring to Embodiment 1, the vacuum chamber 1.1.1 is set as a tapered hole. The suction disc 1 is made of aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com