A semiconductor production device

A technology for production equipment and semiconductors, which is used in semiconductor/solid-state device manufacturing, fine working equipment, electrical components, etc. It can solve the problems of unstable pressing of semiconductors and low cutting quality of semiconductors, so as to improve cutting quality and improve cutting stability. , Improve the effect of clamping flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

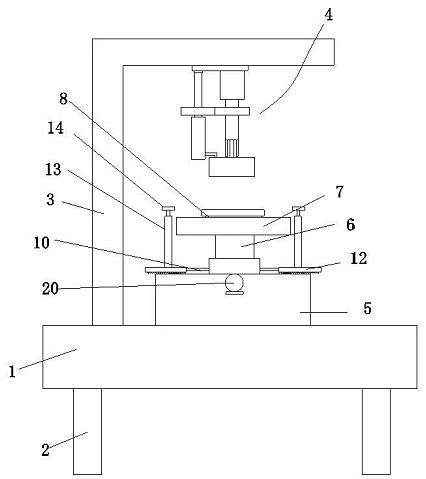

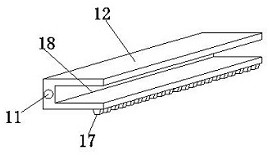

[0034] Embodiment one, by Figure 1 to Figure 8Given, the present invention includes a base 1, the bottom of the base 1 is symmetrically provided with a support column 2, the top of the base 1 is provided with a support frame 3, the inner top of the support frame 3 is provided with a cutting mechanism 4, and the top of the base 1 is provided with a The support platform 5 below the cutting mechanism 4, the top middle position of the support platform 5 is provided with a mounting base 6, the top of the mounting base 6 is provided with an operating table 7, and the top of the operating table 7 is provided with a metal placement plate 8, through which the metal placement plate 8 The design is convenient for cutting the semiconductor placed on the top of the metal placement plate 8, and then can realize the protection of the console 7. The two sides of the mounting base 6 are symmetrically provided with a slide plate 12, and the bottom end of the slide plate 12 is equidistant from o...

Embodiment 2

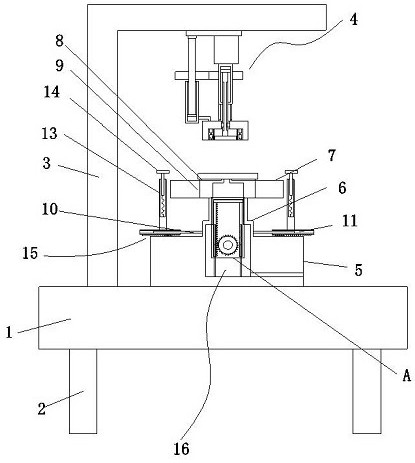

[0037] Embodiment two, on the basis of embodiment one, by image 3 , Figure 4 with Figure 5 Given, one side of the support table 5 is provided with a mounting plate 19, and the slide plate 12 is provided with a groove 2 18 which is slidably connected with the mounting plate 19. By the design of the mounting plate 19 and the groove 2 18, it is convenient to make the slide plate 12 Sliding on the mounting plate 19 has effectively improved the stability of the movement of the slide plate 12. The middle position on both sides of the console 7 is provided with a groove-9 that is sleeved on the outside of the moving cylinder 13. Through the design of the groove-9, it is convenient The moving cylinder 13 is moved to both sides of the metal placing plate 8 to facilitate the clamping of the semiconductor on the top of the metal placing plate 8. The clamping rod 14 is a T-shaped structure, and the bottom end of the clamping rod 14 is in contact with the inner surface of the moving cy...

Embodiment 3

[0038] Embodiment three, on the basis of embodiment one, by figure 1 , figure 2 , Figure 5 , Image 6 with Figure 7 Given, the metal placement plate 8 is a concentric circle structure, the top of the console 7 is provided with a ventilation hole 30 located in the center of the metal placement plate 8, the interior of the support table 5 is provided with a receiving groove 31, and the interior of the mounting seat 6 is provided with a Accommodating groove 31 and vent hole 30 are communicated communication groove 32, and adsorption mechanism 16 comprises gear four 33, tooth plate 34, piston plate 35, stabilizer one 36, fixed rod 37 and movable groove 38, is connected on the rotating shaft two 22 The gear four 33 that is positioned at the interior of the accommodation groove 31 is movably connected with a piston plate 35 inside the communication groove 32, and the bottom end side of the piston plate 35 is provided with a tooth plate 34 meshingly connected with the gear four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com