Automatic orientation control system used for notched workpieces

A technology of orientation control and workpiece, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of manual orientation, time-consuming, labor-intensive, and poor efficiency, and achieve the effect of ensuring normal work, convenient operation, and high use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

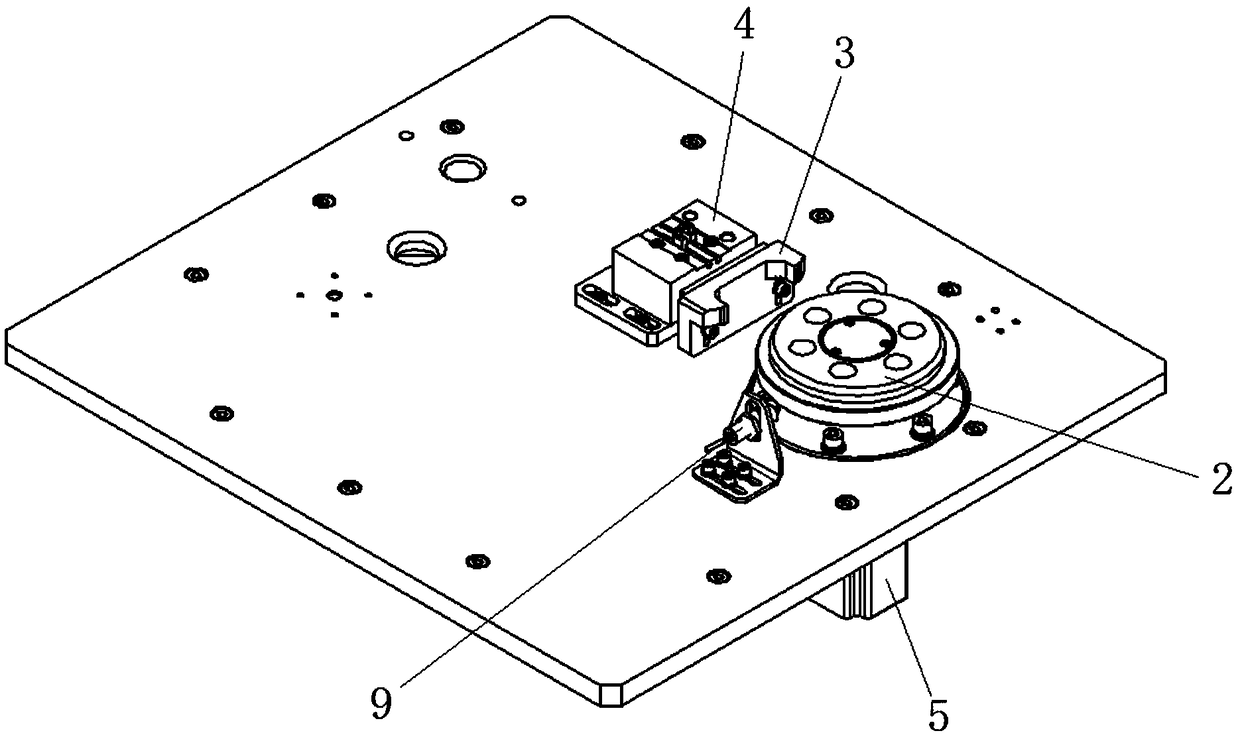

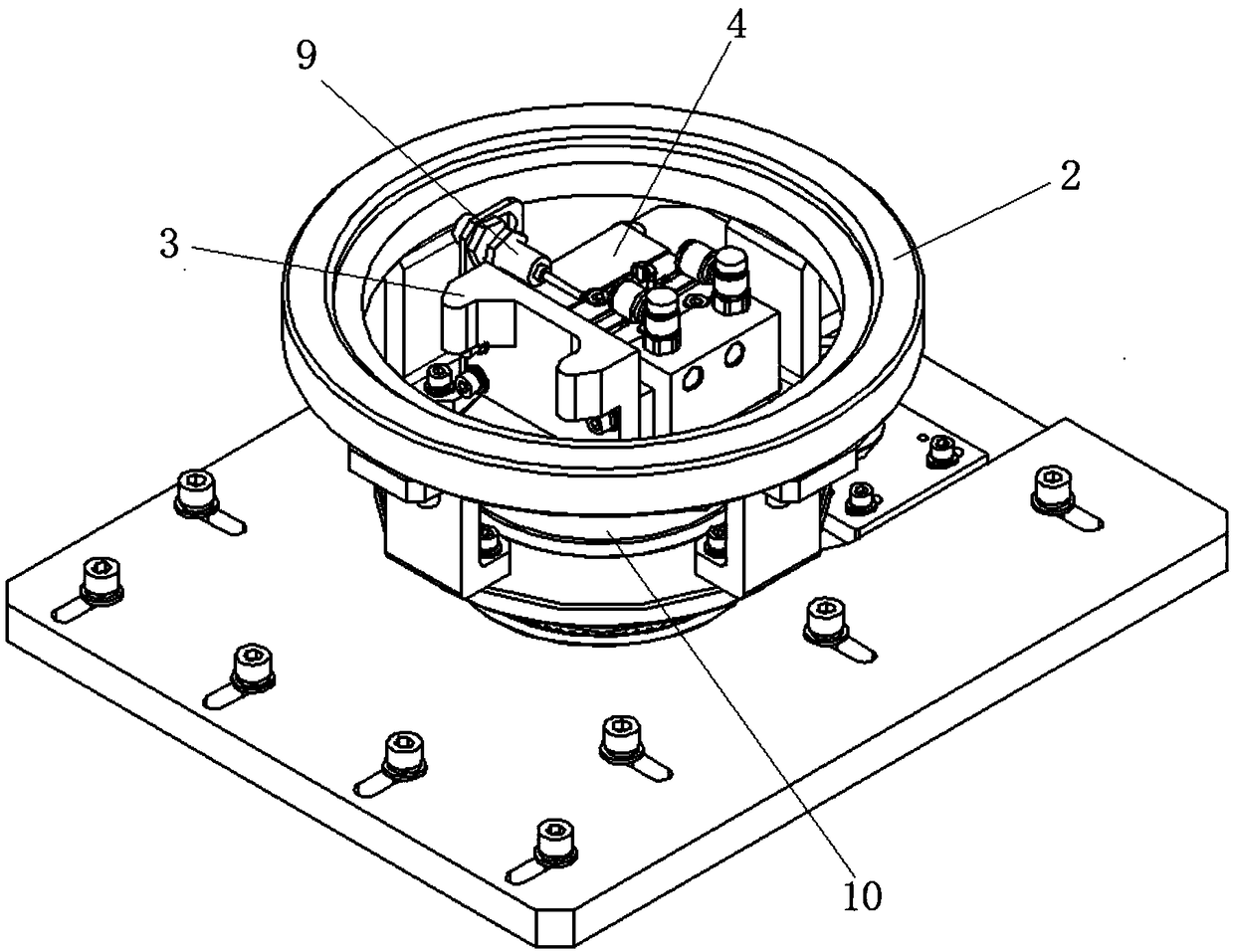

[0016] Attached below Figure 1-2 A first embodiment of the present invention will be described.

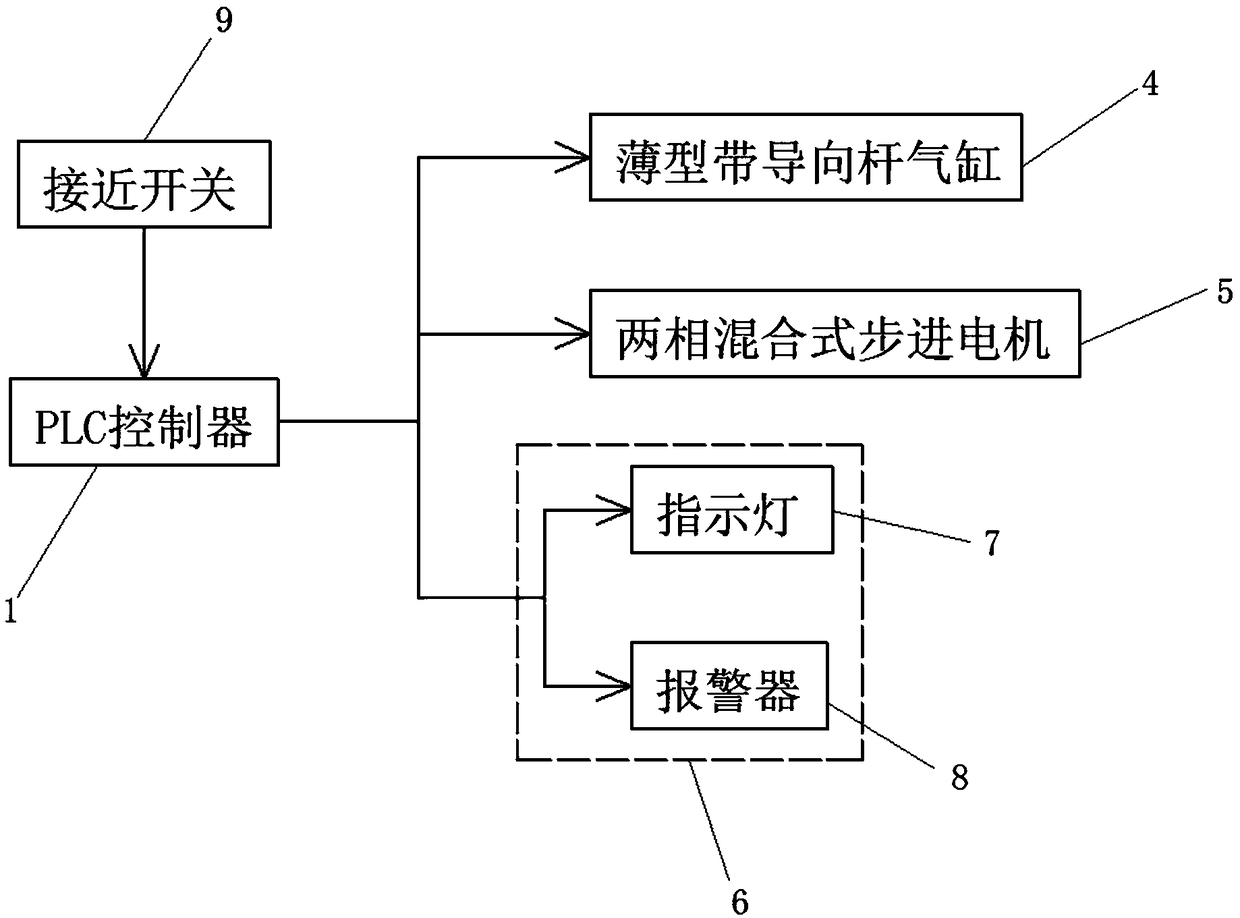

[0017] An automatic orientation control system for workpieces with notches, including a PLC controller 1, a notch position detection unit, a workpiece orientation unit and a power drive unit, the PLC controller 1 is connected to the notch position detection unit and the notch position detection unit is connected to the workpiece Corresponding to the position of the gap, the PLC controller 1 is connected to the workpiece orientation unit and the power drive unit, and the PLC controller 1 controls the power drive unit to connect and drive the workpiece pallet 2 for installing the workpiece. After the rotation, the gap position detection unit detects the gap of the workpiece , the PLC controller 1 controls the power drive unit to stop and start the workpiece orientation unit according to the gap position information fed back by the gap position detection unit, and then the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com