Synthetic preparation method of multi-layer graphite nanosheets hybrid transparent polyimide film and product thereof

A technology of transparent polyimide and nano-graphite sheet, which is applied in the field of multi-layer nano-graphite hybridized transparent polyimide film and its preparation, to achieve the effects of easy identification, clear and visible color changes, and avoiding sudden accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

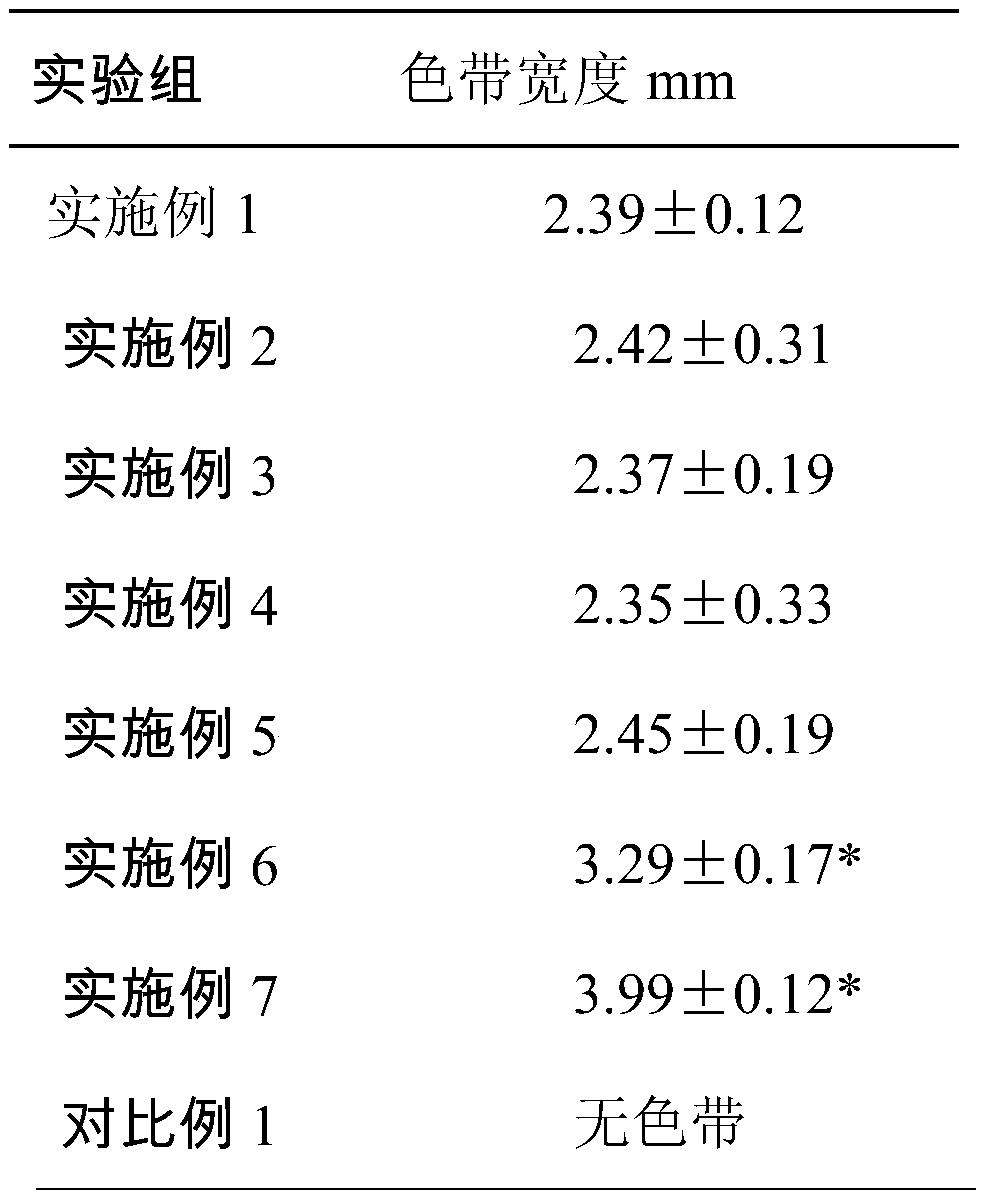

Examples

Embodiment 1

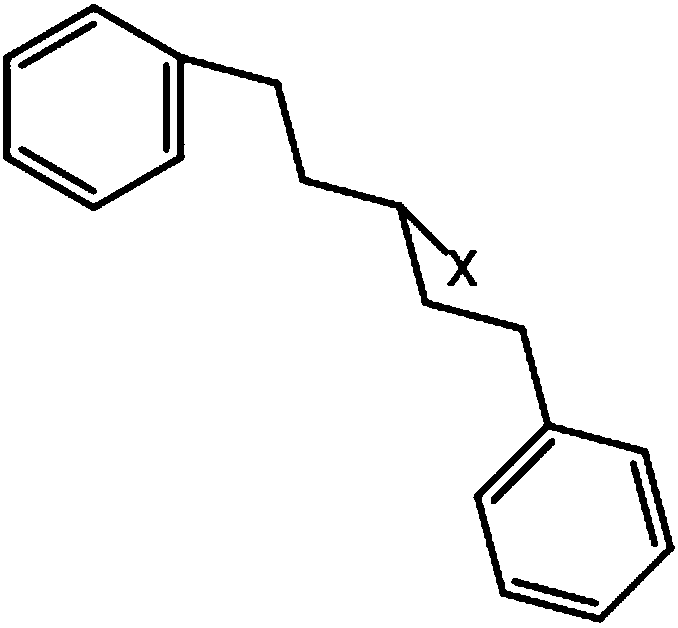

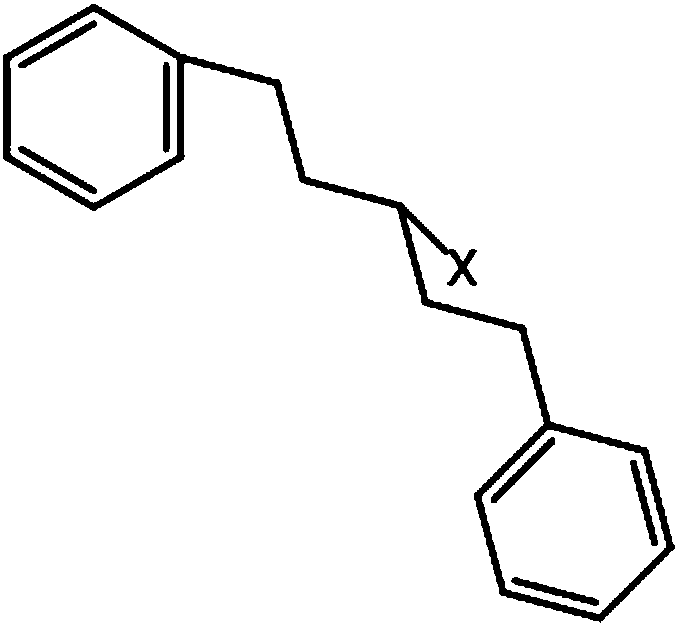

[0024] A multi-layer nano-graphite flake hybrid transparent polyimide film, comprising the following materials in parts by weight: 350 g of polyimide, 5 g of nano-graphite, and 8 g of 1,2,3,10b-tetrahydrofluoranthene.

[0025] The preparation method of the above-mentioned multi-layer nano-graphite hybrid transparent polyimide film is carried out according to the following steps:

[0026] (1) At room temperature, 1180g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane and 990g of 4,4'-oxydiphthalic anhydride were added to the reactor, under nitrogen protection Add 15000g of m-cresol, stir evenly, add 500g of isoquinoline, heat up to 190°C, react for 12 hours, after cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin;

[0027] (2) 5g of nano-graphite is placed in 500g of N-methylpyrrolidone, pre-dispersed after high-temperature treatment by a high-shear disperser, and the treatment temperature is 500°C;

[0028] (3) Get prepared polyimide resin 3...

Embodiment 2

[0033] A multilayer nano-graphite flake hybrid transparent polyimide film, comprising the following materials in parts by weight: 200 g of polyimide, 3 g of nano-graphite, and 3 g of 9-ethylfluorene.

[0034] The preparation method of the above-mentioned multi-layer nano-graphite hybrid transparent polyimide film is carried out according to the following steps:

[0035] (1) At room temperature, add 1108g 2,2'-bis(trifluoromethyl)benzidine and 880g pyromellitic dianhydride to the reaction kettle, add 13000g m-cresol under the protection of nitrogen, stir well, add 400g isoquinoline, heated up to 170°C, reacted for 10 hours, after cooling, poured the reaction solution into ethanol to precipitate, and made polyimide resin;

[0036] (2) 3g of nano-graphite is placed in 300g of N-methylpyrrolidone, pre-dispersed after high-temperature treatment by a high-shear disperser, and the treatment temperature is 300°C;

[0037] (3) Get 200g of the prepared polyimide resin, add in the nano-...

Embodiment 3

[0042] A multilayer nano-graphite sheet hybridized transparent polyimide film, comprising the following materials in parts by weight: 500 g of polyimide, 12 g of nano-graphite, and 12 g of 9-benzylfluorene.

[0043] The preparation method of the above-mentioned multi-layer nano-graphite hybrid transparent polyimide film is carried out according to the following steps:

[0044] (1) At room temperature, add 1320g α, ω-bis(methylamino)polydimethylsiloxane and 1010g bisphenol A dianhydride to the reaction kettle, add 15000g m-cresol under nitrogen protection, and stir evenly , add 500g of isoquinoline, heat up to 200 ° C, react for 14 hours, after cooling, pour the reaction solution into ethanol to precipitate, and make polyimide resin;

[0045] (2) 12g of nano-graphite is placed in 600g of N-methylpyrrolidone, pre-dispersed after high-temperature treatment by a high-shear disperser, and the treatment temperature is 800°C;

[0046] (3) Add the synthesized polyimide resin and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com