Optical element coating device and coating method

A technology of optical components and coating devices, which is applied in the field of thin film optical preparation and optical equipment, can solve the problems that the coating machine cannot place baffles, etc., and achieve the effects of improving scientific research and production efficiency, reducing the number of experiments, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

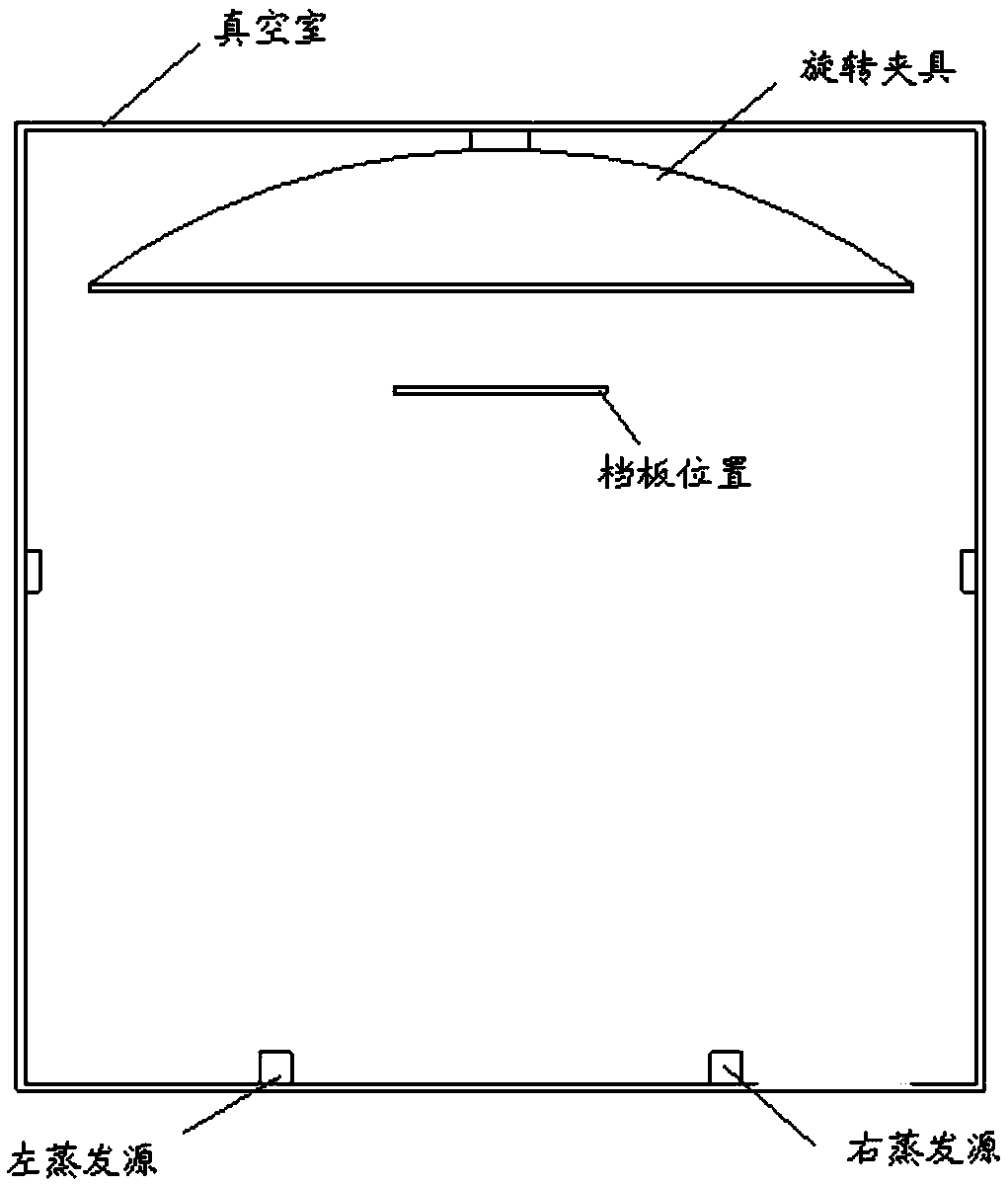

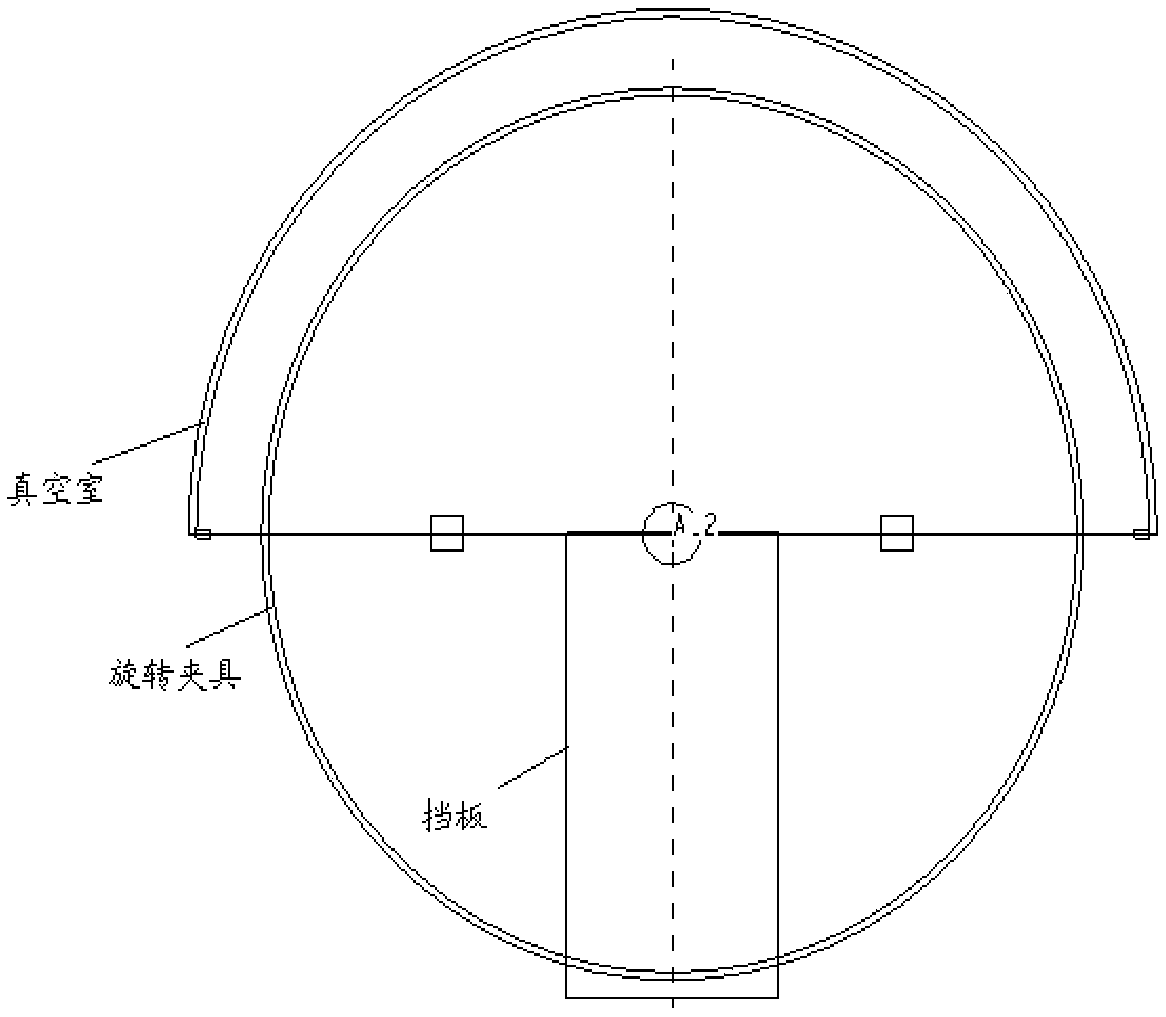

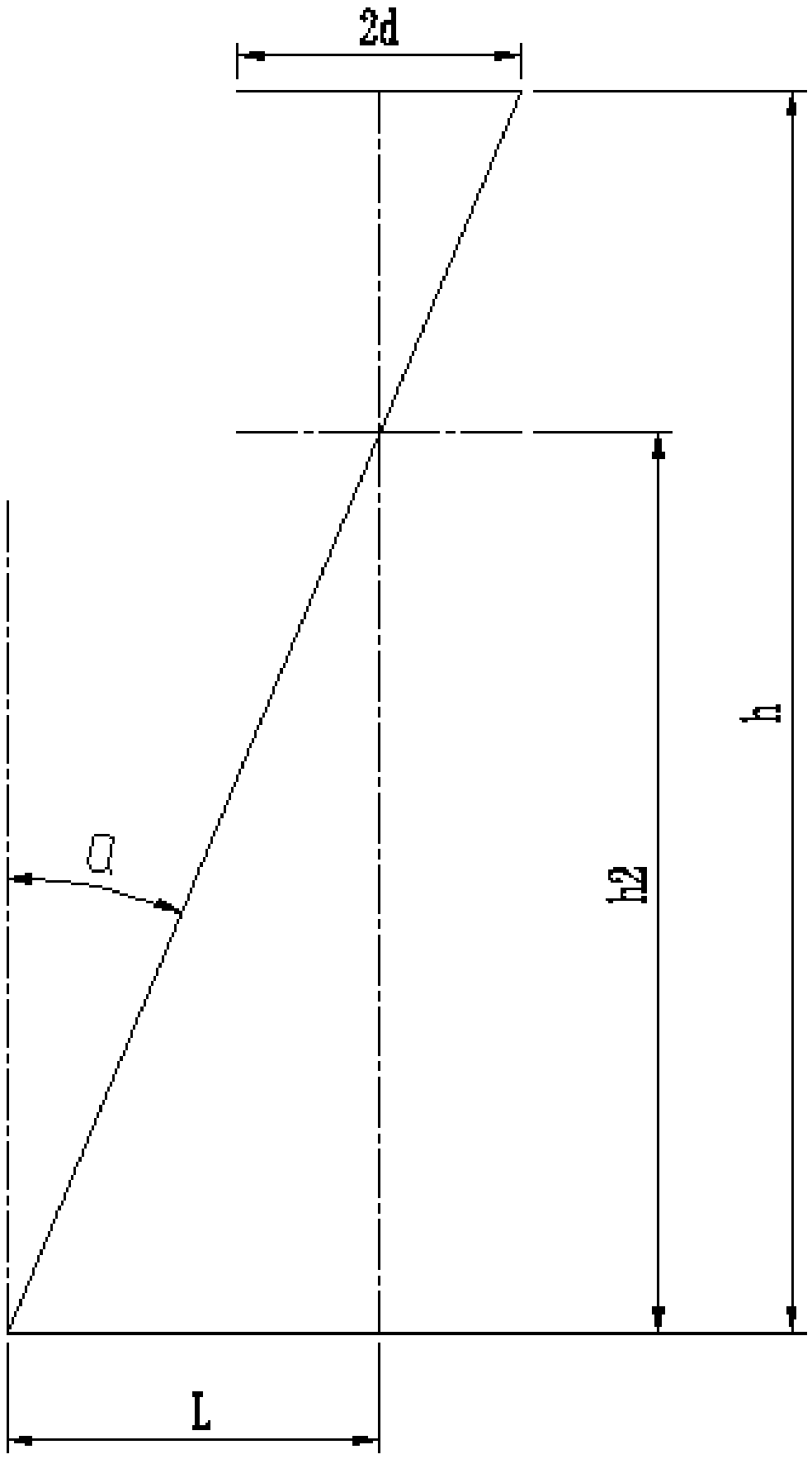

[0070] Such as Figure 1-4 As shown, a coating device for an optical element, the coating device includes a coating machine and a baffle; the coating machine includes a vacuum chamber, a left evaporation source, a right evaporation source and a fixture, and the left evaporation source and the right evaporation source are placed in the vacuum chamber At the bottom, the fixture is fixedly installed on the top of the vacuum chamber, the baffle is placed in the vacuum chamber of the coating machine, and the distance between the center of the baffle and the center of the left evaporation source is the same as that of the center of the right evaporation source; the fixture is used for coating and the distance between the center of the left evaporation source and the center of the bottom end of the vacuum chamber is L=1150mm, the distance between the center of the right evaporation source and the center of the bottom end of the vacuum chamber is L=1150mm; the maximum evaporation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com